The ability to consume energy in portable products is growing faster than the ability to supply it. Also, electrochemical devices are inherently dangerous.

Furthermore, all portable and rechargeable devices must be managed in accordance with the battery laws. With this in mind, battery management can be divided into three elements: recharge, safety and security, and runtime estimation.

Battery charge system requirements are simply stated as "the desire to recover the battery to a full state of charge as quickly as possible without harm to the battery or user". To accomplish this task, one must first target customer expectations. Equipment runtime ranges from 20 minutes, in the case of a power tool, to five days for a voice-only cellphone. With exceptions, recharge time naturally follows what is perceived as an acceptable period of user downtime. User downtime for the previously cited examples can vary from a 10-minute coffee break to overnight. The standard exceptions are based on the question, "How much is the customer willing to pay for minimal downtime?"

Though charge regimes vary as a function of the battery technology employed, all must adhere to the conversion of power from a source, whether it is a wall plug, car adaptor, another battery, or, in the near future, a fuel cell.

The object of the power converter is to deliver charge to the battery in a form suitable to the cell technology with an efficiency that is compatible with the economic and environmental goals. Examples of topologies range from, on the high end, an AC-to-DC switching constant-current controller with power factor correction for the professional power-tool market to a linear constant-current constant-voltage circuit for cellular applications. Again, the choice here is based on economics: the 'switcher-fast' charger metric is up and to the right on a cost vs performance curve as opposed to 'linear-slow' charge.

The charge regime must also comprehend termination of charge when the battery is full. The term 'charge termination' refers to the rule established for ending battery charging and is a requirement for achieving acceptable battery service life. Li-Ion batteries are charged at a constant current rate, between 1/10 to three times the rated capacity, until voltage compliance is reached. Voltage must be held to ½% accuracy within the range from 4,1 V to 4,4 V per cell, depending on the technology under charge. Maintaining this compliance voltage is critical to the health of both the battery and user. Termination of charge occurs either when the charge current falls to a minimum limit or when a specified charge time is exceeded. One of the more interesting ideas lately is that of storing charge parameters in the pack electronically in order to modify the charge process to the particulars of the battery under charge. This capability allows greater flexibility for the end equipment when it comes to packs from multiple suppliers or batteries with differing performance ratings.

Battery safety is an issue of growing concern, as witnessed by current press and standards body activity. When properly used, a Li-Ion cell will provide hundreds of charge cycles, possibly outlasting the service life of the portable equipment. Unlike the NiMH technology powering the portable products of the '90s, this technology is unforgiving with regards to over-charge or poor cell construction. Abuse may result in permanent loss of capacity, swelling of the cell, and even explosion and fire. It is common practice to employ redundant safety measures in order to avoid single-point failures. For example, in addition to precisely controlling charge voltage, redundant safety elements are employed within the battery pack to break the electrical connection in the event of a runaway charge or short circuit.

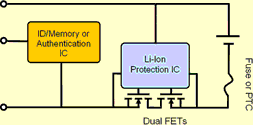

These measures are effective only if they are employed. Unfortunately, by their nature, a product with a removable battery pack begets an aftermarket for packs of varying quality. To combat the hazards of unauthorised battery cloning, the OEM may implement means to authenticate the origin of the pack. Solutions range from stickers of authenticity to silicon authentication. Pack-resident devices for this purpose may be as simple as a resistor or ROM identifier or as daunting to the counterfeiter as cryptographic authentication.

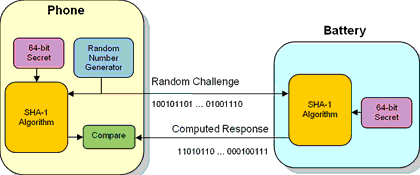

Crypto-solutions work as follows: the phone sends a challenge, then the battery provides a response. If the response is the appropriate one, the battery is authenticated and therefore can be managed. The efficacy of such a scheme depends on the strength of the algorithm, the challenge periodicity, and ease of physical attack of the device used.

In addition to fast charging and safety, knowing the available runtime is important to meeting user's needs. Remaining runtime estimation is probably the most misunderstood and least appreciated of the three functions mentioned in this article. For example, a Smartphone rings a chime that warns of a low battery condition and is configured to provide 72 hours of battery life in standby operation before losing both data and programs in its volatile memory. How does the device know with any certainty when to cease user operation? If the device were to use a voltage level to determine when to go to standby, the uncertainty in the selection of a cutoff point could be as high as 30% of the battery capacity. That is to say that due to variations in temperature, rate of discharge, and age of the battery, the user will be prematurely ejected from completing a task because the system does not really know how much energy is available. More sophisticated solutions using current accumulation, temperature, rate of discharge, and battery impedance, in addition to voltage, yield remaining capacity estimates with accuracies of 5% or better. Employing these types of solutions allows the user to extract more runtime from a given battery while providing continuous battery runtime and time-to-full-charge status information. Without accurate capacity information, the user is uninformed or misinformed about how long the equipment can be used.

Without a major advance in cell technology, the goals of more runtime, less downtime, and a safe user experience will fall under the province of electronic control. These issues become more acute with continual user demand for function, connectivity, and portability. To this end, electronic content addressing recharge, safety and security, and accurate runtime estimation is key to customer satisfaction.

For more information contact CST Electronics, +27 (0)11 608 0070.

© Technews Publishing (Pty) Ltd | All Rights Reserved