Loudspeakers and amplifiers are manufactured by numerous companies building one or both of the systems.

Different design parameters cause impedance mismatching which can be damaging to speakers.

Over-current situations caused by overdriving power amps can damage the wirewound coils, causing shorts or opens in the copper windings of speaker components. Low power amps may act as clippers, causing a frequency shift or high frequency signals which can damage speakers, tweeters and constant directivity horns.

Another common failure mode is caused by taking a speaker from a zero state to a highly excited state in an extremely short period of time. The design of crossover networks concerns itself with the load seen from the amplifier. The initial internal resistance of the device is extremely small compared to the total impedance of a crossover circuit such as a Zobel network or conjugate impedance network.

The obvious solution is circuit protection using over-current protection devices. Two choices are fuses and circuit breakers. Circuit breakers can add undesirable distortion as the metal contacts separate. The electric field generated by the current flow resists the change in current, resulting in arcing and electrical white noise.

Fuses must be accessible and manually replaced. The cost of the fuse, fuse holder and access panel to the fuse makes typical fusing economically unattractive. Also, there is the possibility of mistakenly or intentionally over-rating the fuse, setting the system up for damage and violation of agency safety certifications. In crossover networks, a minimal number of components is used to protect the tweeter.

The obvious solution is to use an inexpensive resettable fuse that can be buried in the cabinet without needing maintenance or replacement.

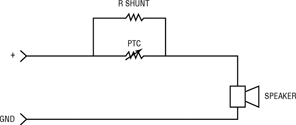

A Multifuse PPTC from Bourns can be used in a parallel circuit with a large resistor (typically 10 kΩ) and this circuit is placed in series upstream of the speaker - see Figure 1.

During normal operation within the parameters of the tweeter, the PPTC acts as a conductor for the speaker. When an over-current situation such as an overdriven amp occurs, the polymer within the PPTC will expand and the carbon chains will disengage. This shunts all of the current through the shunt resistor, dropping the voltage across the resistor and protecting the speaker. Once the signal changes to a low value, the PPTC will begin to reset and the circuit will react as designed.

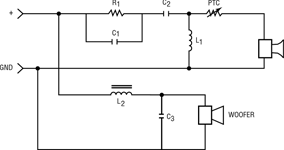

Another application is to use the PPTC without a shunt resistor - see Figure 2. As the PPTC's resistance increases exponentially, the speaker, horn or other delicate instrument will see little to no current flow.

The choice of PPTC depends upon the current demanded by the parameters of the speaker which the PPTC protects during normal operation. The Ihold of the PPTC is the amount of operational current desired in the design. The Itrip is the value at which the designer wishes to begin protecting the circuit, keeping in mind that the ambient temperature is an integral part of the circuit design when selecting the correct device.

Figure 2 shows a typical crossover network design, with typical values as follows:

C1: Ranges from 2 to 10 μF.

R1: Ranges from 2,7 to 22 Ω.

C2: Ranges from 2,2 to 4 μF.

L1: Ranges from 300 to 450 μH.

L2: Ranges from 0,7 μH to 2,5 mH.

C3: Ranges from 4,7 to 33 μF.

The input voltage can range up to 60 Volts continuous for newer speaker systems and about 53 Volts on older systems. Typical music peaks are a minimum of 12 db and normally 15 db. New woofers can handle 500 Watts while older styles are limited to 350 Watts. Tweeters fall into values of 60 Watts for new speakers, and 40 Watts for older speakers.

© Technews Publishing (Pty) Ltd | All Rights Reserved