Circuit protection using PTC resettable fuses

29 October 2008

Circuit & System Protection

Information from Bourns

It is frequently necessary to separate a part of a circuit from the power source while maintaining the integrity of the remaining circuit in a working status. In instances where a part of a system could be damaged and the remaining section will need to continue to operate, the following circuit design, employing a PPTC (polymetric positive temperature coefficient) resettable fuse is an option.

In this example application, a series of circuits are attached to the secondary side of the transformer or single bus bar from the power supply. The total resistance of each circuit branch is calculated using the algebraic form of Ohm’s law (voltage = resistance x current.) Typically, the inductance and capacitance are negligible when compared to the overall impedance of the device. In series, the resistance is added directly.

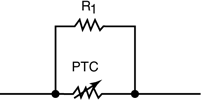

Figure 1.

R(T) = R1 + R2

(Calculation 1)

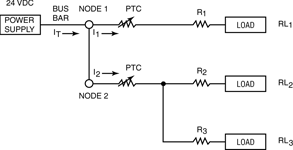

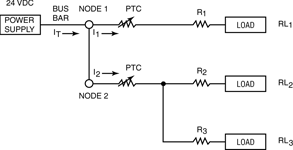

Resistances in parallel are added using the parallel resistance formula R(T) = 1/((1/R1)+(1/R2)) where R(T) is the total resistance of the two resistors in parallel. R1 and R2 (see Figure 2) are the values of the resistors in the parallel circuit.

Figure 2.

R(T)= 1/((1/R1) + 1/(R2))

(Calculation 2)

A Bourns Multifuse PPTC device can be chosen depending on the value of each branch resistance and the voltage applied – see Calculation 3 and Figure 3. With the known voltage of the power supply and the calculated value of the branch circuit, we can determine the current of the branch. For the branch at node one, the calculated resistance is 8 Ω. We then determine the current using the voltage of 24 volts and Ohm’s law. The current is 3 amps, so we choose the MF-R300. In the same way, the value of current at node 2 is determined to be 2 amps, so the MF-R200 is chosen.

Figure 3.

R(T1) @node 1 = R1 + RL1 = 8 O

R(T2) @node 2 = 1/((1/(R2 + RL2)) + (1/(R3 + RL3)) = 12 Omega;

V = IR

V = I1 (R1 + RL1) = I1 8 O V = 24 V d.c.

24 V d.c./8 O = 3 Amps = I1 @ node 1

V = IR</b>

V = I2 R(T2) = I2 12 Omega; V= 24 V d.c.

24 V d.c./12 O = 2 Amps = I2 @ node 2

The Ihold for the PPTC device R1 at Node 1 will be 3 amps, so an MF-R300 will be chosen

The Ihold for the PPTC device R2 at Node 2 will be 2 amps, so an MF-R200 will be chosen

I(T) for the circuit will be I1 + I2 = 5 amps. So the Imax over current rating of the PPTC is not violated.

(Calculation 3)

If the overall resistance is calculated (see Calculation 2), the current can be solved by using Ohm’s law. The overall current calculation should equal the sum of the current at node 1 (I1) and node 2 (I2) where I(T) = I1 + I2.

If there is a short circuit at load RL2, the current, which is the same current through the MF-R200 at node 2 (R2), will rise. As this occurs, the I2R will also rise. As the I2R rises, the resistance of the PPTC will rise exponentially. According to Ohm’s law, as the resistance rises, the current will drop sharply.

This will not affect the circuit at node 1. The current will be blocked from node 2 until the fault condition is removed and the PPTC is reset through thermal radiant dissipation. The entire resistance of node 2 becomes exponentially high, causing I2 to go towards 0 amps. Thus the total current I(T) = I1.

Further reading:

Smarter protection without disruption

NewElec Pretoria

Circuit & System Protection

Designed for operations still running without integrated automation, NewElec’s retrofit-friendly systems let you upgrade performance and safety without overhauling your entire network.

Read more...

Circuit breaker for reliable, compliant protection

RS South Africa

Circuit & System Protection

Legrand’s low-voltage power distribution portfolio encompasses the DX3 range of miniature circuit breakers, designed to deliver dependable protection in residential, commercial and industrial installations.

Read more...

Reducing noise on power supply lines

Future Electronics

Circuit & System Protection

Murata has introduced the EMIFIL ESD Series Noise Filters, a breakthrough solution engineered for superior noise suppression and enhanced electrostatic discharge (ESD) protection.

Read more...

Clearing the Static: Fundamental principles of static control

Actum

Circuit & System Protection

Controlling electrostatic discharge in electronics manufacturing is essential with effective ESD programs built on six key principles.

Read more...

Electrical fire safety in lithium-ion battery rooms

Circuit & System Protection

Pratliperl is a non-combustible, ultra-lightweight aggregate that can be mixed with cement and applied as a plaster or screed to walls, floors, and ceilings.

Read more...

Clearing the Static: ESD training in the workplace

Actum

Circuit & System Protection

To protect sensitive electronic components, A structured, consistent, and sustainable ESD training program is essential.

Read more...

Protect your pumps – protect your profit

NewElec Pretoria

Circuit & System Protection

In South Africa’s demanding agricultural landscape, irrigation is not just an essential service – it is the heartbeat of farm productivity.

Read more...

Clearing the Static: ESD and installation: A durable antistatic solution

Actum

Circuit & System Protection

ESD flooring provides a reliable, long-term solution for managing static electricity by safely dissipating static charges through the floor to a designated ground point.

Read more...

Why wait to automate

NewElec Pretoria

Circuit & System Protection

NewElec’s initiative helps you gain operational visibility via HMI or PLC by retrofitting intelligent motor protection relays without replacing MCCs or rewiring the plant.

Read more...

Clearing the Static: Effectively control static in your workplace

Actum

Circuit & System Protection

Controlling electrostatic discharge in the workplace is crucial to protect sensitive electronic equipment from damage. Implementing an ESD control program involves various measures and tests.

Read more...