Cabinet coolers use vortex technology

12 November 2008

Enclosures, Racks, Cabinets & Panel Products

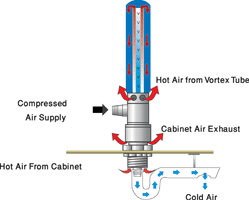

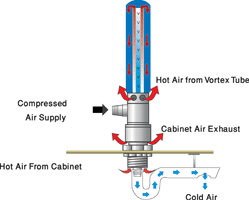

Cabinet coolers from Exair provide a low-cost, reliable way to cool and purge electronic control panels. Their functioning employs a vortex tube to produce cold air from compressed air, with no moving parts. The compact units can be installed in minutes through a standard electrical knockout. NEMA 4, 4X and 12 cabinet coolers are available in many cooling capacities for large and small control panels.

The vortex tubes incorporated in the coolers are constructed of stainless steel, whose wear, corrosion and oxidation resistance ensures long life and maintenance-free operation.

How the cabinet coolers work

Compressed air enters the vortex tube and is converted into two streams, one hot and one cold. Air from the vortex tube is muffled and exhausted through the vortex tube exhaust, while cold air is discharged into the control cabinet through the cold air distribution kit. The displaced hot air in the cabinet rises and exhausts to atmosphere through the cabinet air exhaust at a slight positive pressure. Thus, the control cabinet is both cooled and purged with cool, clean air and outside air is never allowed to enter the control panel.

This cooling system has several advantages over conventional methods. Heat exchangers and heat pipes have serious limitations when it comes to summertime heat. In many cases, the temperature of the hot plant on a summer day is close to that inside the enclosure. There is not enough difference in temperature for a decent exchange. These also rely on electricity to run.

Refrigerant panel airconditioners are expensive, take almost a day to install, and are prone to failure when dust and dirt clogs the filter. Vibration from machinery contributes to component failures and loss of Freon. Life expectancy for most compressors is rated at 2,5 years of continuous operation. Often a floor drain is not readily available for the condensation tube. These units also require electricity to run.

According to Exair, heat exchangers, heat pipes and refrigerant coolers all have filters that can clog. Left unattended, mechanical failure of the cooler is likely, resulting in overheating inside the enclosure and possible equipment failure. Vortex coolers have no moving parts to wear out and do not require constant monitoring. All models are UL listed and available in a large number of styles and capacities.

Thermostat control limits compressed air use by operating the cooler only when the enclosure reaches predetermined levels. Most plants have their compressor running continuously; by using a vortex cooler, energy savings are achieved through utilising a machine that is already consuming electricity, instead of using products which would require additional power.

Typical applications are found in the food and pharmaceutical industries with capacities ranging from 160 to 700 kilo calories per hour.

Further reading:

Smart track busway for scalable power delivery

RS South Africa

Enclosures, Racks, Cabinets & Panel Products

The latest generation Legrand Data Center Track Busway system combines mechanical safety, smart diagnostics, material efficiency, and modular flexibility to provide a dependable platform for optimised power distribution.

Read more...

Cabinets for industrial applications

Vepac Electronics

Enclosures, Racks, Cabinets & Panel Products

Verotec’s VERAK cabinets addresses the most stringent enclosure requirements providing both IP65 environmental protection and EMC screening.

Read more...

Battery modules with lithium iron phosphate technology

Phoenix Contact

Enclosures, Racks, Cabinets & Panel Products

With its new lithium battery modules with IQ Technology, Phoenix Contact is expanding its portfolio with powerful energy storage solutions with a capacity of 284 Wh.

Read more...

Transporting and storing lithium-ion batteries

Enclosures, Racks, Cabinets & Panel Products

Lithium-ion batteries have become ubiquitous in modern life, but along with their benefits comes a serious challenge: these batteries pose fire and safety risks and are classified as dangerous goods for transport.

Read more...

Non-contact safety door switch

Omron Electronics

Enclosures, Racks, Cabinets & Panel Products

OMRON has unveiled its latest innovation in non-contact safety door switches, the D40A-2, designed to enhance workplace safety and streamline machinery operations.

Read more...

Easy installation panel mount assembly

Future Electronics

Enclosures, Racks, Cabinets & Panel Products

NKK’s new easy installation Panel Mount Assembly (the BYB201-470) consists of a PCB, resistor, connector, and a straight PC adaptor.

Read more...

RF shield box to 12 GHz

Vepac Electronics

Enclosures, Racks, Cabinets & Panel Products

The HDRF-1467-S from RF Electronics has a thick RF-absorbing foam that deadens standing waves and reflections to provide more than 100 dB of isolation.

Read more...

High visibility 4-digit panel ammeters

Electrocomp Express

Enclosures, Racks, Cabinets & Panel Products

The MP-335PAS-1 is a 4-digit 7-segment red display ammeter with a measurement range of 4 to 20 mA and a very low power consumption.

Read more...

Multi-channel SMPS cable assemblies

RFiber Solutions

Enclosures, Racks, Cabinets & Panel Products

Withwave’s multi-channel SMPS cable assemblies (WMCS Series) provide a wide range of multiple coaxial connectors and flexible cable assemblies with a choice of

26,5, 40, 50 and 67 GHz configurations.

Read more...

Building the control panels of the future

Omron Electronics

Enclosures, Racks, Cabinets & Panel Products

The industrial automation world is built on robust and efficient control panels that are designed precisely and assembled to manage machines, processes and equipment across different industries.

Read more...