Fumes and gases in industrial areas are very often dangerous to the people working in these areas. Some of these products are visible, but others are not visible or even noticeable. Many of these fumes and gases are toxic and lead to occupational asthma and allergic reactions.

Occupational asthma is a major issue in electronics manufacturing because when a person has developed occupational asthma he/she has to be removed from the working area. In some countries occupational asthma due to flux fumes/isocyanate has already led to legal claims from employees.

Occupational asthma is a disease characterised by variable air flow limitation and/or airway hyper-responsiveness due to causes and conditions attributable to a particular occupational environment and not to stimuli encountered outside the workplace.

Its diagnosis depends on four requirements being fulfilled, namely that there should be a sensitising agent present, the individual should have been exposed to the agent, the symptoms should improve when away from work and should recur when further exposure takes place.

Occupational asthma can be categorised into two types:

When the symptoms of chest tightness, wheezing, shortness of breath, dry cough, etc, appear after a latent period of occupational exposure.

When occupational asthma is associated with an exposure to high concentrations of irritants, the symptoms may somewhat differ from that of asthma that follows a latent period. This is often referred to as RADS (reactive airways dysfunction syndrome).

Lung structure and function

The airways of the lung derive from the trachea (wind pipe) downwards by progressive division into two or more branches. Those airways beyond the trachea that contain cartilage are called bronchi. The airways lacking in cartilage beyond the bronchi are the bronchioles. These lead into hollow spaces called alveoli which have a diameter of about 0,1 mm each.

There are approximately 300 million alveoli and their total surface is about 140 m². The conducting airways are lined with cells with cilia, or small motile surface projections. Interspersed between these cells are mucus secreting cells. Secreted mucus spreads over the cilia which direct it upwards to the larger airways by rhythmic undulating movements, thus helping to clear deposited dusts.

The respiratory units ie, the alveoli and the smallest bronchioles called respiratory bronchioles are responsible for the exchange of gases. They are lined mainly by flat, extremely thin cells which permit easy diffusion of oxygen through them from the air in the alveolar spaces to the blood in the capillaries and easier diffusion of carbon dioxide in the opposite direction.

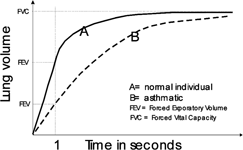

It can be seen from the accompanying graph that trace B rises more slowly in the case of an asthmatic, so that after one second very much less air has been exhaled, or it will take a longer period of time to exhale the same amount of air.

Imagine the lung as a series of tubes along which air flows in and out. When the tubes are narrowed, the same amount of air can flow along the tubes but it will take longer and in addition the airflow will become noisy. This is the effect of asthma because the tubes are narrowed and the breathing process takes a longer period for the same amount of air.

Symptom

There is a latent period between first exposure and the onset of symptoms. This is the period required for sensitisation and may range from a few months to 20 years, but an average is four years. The sensitising agent will therefore have been in use for some time before symptoms develop.

Asthmatic reactions of workers with occupational asthma show different forms:

* Immediate asthmatic reaction. This starts within minutes of exposure and lasts 1 to 2 hours after exposure has ended.

* Late asthmatic reaction. This is the most common reaction and due to the fact that it starts up to 18 hours after exposure, the occupational cause can be overlooked. In the majority of cases the symptoms appear in the evening and at night.

* Recurrent asthmatic reactions. Cases have been documented where a single exposure has led to continuing symptoms for days or weeks even when not being present on the work floor but in office areas away from the factory, due to the fact that the sensitising agent was spread with the central ventilation system. When being exposed for a longer period the asthmatic reactions can be much more prolonged.

Sensitising agents

A wide range of chemicals and agents of biological origin have been described as causes for occupational asthma. Workers may be unaware of the possible relationship between their symptoms and their work.

Another important causal agent within the electronics industry is flux containing colophony – rosin/resin which contains abietic acid and other acids. Both di-isocyanates and colophony fumes are low molecular-weight substances and are likely to be more persistent with regards their symptoms to occupational asthma, even after exposure to these materials has ended for a longer period.

On both coated wires and printed circuit boards, solderable enamels are found, which are basically polyurethanes and therefore contain isocyanates. The problem with polyurethane is that when it is heated to soldering temperatures (above 150°C), toluene di-isocyanate (TDI) is given off. It is known that soldering on polyurethane coatings without adequate extraction can exceed the maximum allowed exposure levels almost instantly.

Di-isocyanate exposure, TDI and MDI from exposure in occupations such as work involving polyurethane varnishes or foams, certain waterproofing agents etc, has been shown in the UK to be the major causative agent of occupational asthma.

Four recognisable medical effects of flux fumes are known. These are lacrymation and rhinorrhoea (running eyes and nose), irritation of the throat, asthma and skin irritation. The first two symptoms are acute irritations due to high levels of fumes. As such, these are self-limiting symptoms which disappear when the exposure to the fumes ceases.

Prevention

Low molecular-weight gases such as aldehydes and iso-cyanates are dangerous as they form amines in the human body. Local extraction at the source where the fumes occur, in combination with a filtering system which removes these gases from the airflow, is the only correct solution. Low molecular-weight gases can be filtered through chemical adsorption.

Weller manufactures fume extraction systems which are equipped with a gas filter containing a chemical adsorption process. All of these systems have been tested by independent institutes for their efficiency of filtration of gases such as aldehydes and isocyanates.

| Tel: | +27 11 704 3020 |

| Email: | [email protected] |

| www: | www.ama-sa.co.za |

| Articles: | More information and articles about Allan McKinnon & Associates |

© Technews Publishing (Pty) Ltd | All Rights Reserved