Video walls utilising multicolour LEDs are in high demand, especially if the LED can be mounted using surface-mount technology.

This article deals with the latest red, green and blue (RGB) LED package approaches for full-colour indoor and outdoor displays, as well as technical considerations which designers should take into account when designing these large full colour displays.

SMT products for full-colour LED displays

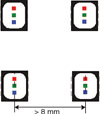

There are different packages available in the market that can be used to build up a video wall using a surface mount approach. For instance, PLCC-2 LEDs can be used to build up a monochromatic display or full-colour display where one pixel is made from multiple LEDs. On the other hand, due to the size of a PLCC-2 LED, the pixel pitch of such a screen can be quite large. This might be acceptable in screens with a distance to the viewer of at least 10–15 metres, but in situations where the viewer is closer to the screen, like at a shopping mall, a finer resolution would be more favourable. 3-in-1 RGB packages enable smaller pixel sizes to be achieved. The most popular 3-in-1 RGB packages are based on either a PLCC-4 or PLCC-6 platform.

Recently, Avago released a new 3-in-1 RGB PLCC-4 LED (ASMT-QTB0), which has highly reflective white package material that provides a high extraction of light. However, a black surface is used on the upper side of the LED to achieve a high contrast ratio. The black surface needs to be non-reflective to absorb as much light as possible shining onto the screen from various sources, eg, spotlights or the setting sun. The pixel pitch of the aforementioned PLCC-4 can go down to 8 mm for high resolution video screens.

A completely black package PLCC-4 leads to an even better contrast ratio, enabling enhanced visual performance and appearance of indoor full colour screens. For example, Avago’s ASMT-QTC0 enables screens to be built with a similar visual appearance to an LCD display, but in much larger sizes.

Another popular package platform for full colour video screens is a PLCC-6 LED which has six leads with an individual anode and cathode for each chip. A highly reflective white package enables good colour mixing and high brightness, making it suitable for outdoor applications. The black surface helps to achieve a high contrast ratio in indoor and outdoor video walls. Additionally, the small package design enables a pixel pitch down to 8 mm. However, for optimum performance, the recommended pixel pitch is 10 mm.

Considerations that help to further improve full-colour screens

Thermal management and LED component behaviour

Higher brightness is one easy way to boost the visual performance of full-colour displays. The ASMT-QTB0 and ASMT-YTB0, for example, have a typical total brightness of 2,1 cd at 20 mA for each chip; the fully black ASMT-QTC0 comes with typically total 925 mcd at 20 mA for each chip. The LED chips are made of semiconductor materials called AlInGaP and InGaN. As it is taught in physics or electronics, semiconductors tend to be quite sensitive to heat. In the case of AlInGaP and InGaN LED chips, this heat leads to a significant decrease in brightness. For example, at 125°C, the light output of a green InGaN chip decreases by up to 40% compared to its performance at 25°C. Therefore, good heat conduction from the LED chip to the supporting PCB or heatsink is essential.

The thermal resistance between the junction of the chip and the pin of the package is about 280 K/W in a conventional PLCC-2 and about 140 K/W for a mono-colour PLCC-4 LED. These values are quite high, especially in the case of a 3-in-1 LED with three chips heating up. Because of this, the package of a multicolour LED has to be designed with the lowest possible thermal resistance. The PLCC-4 ASMT-QTB0 and ASMT-QTC0 have been designed with a typical thermal resistance junction to pin, Rθ-JP of less than 95°C/W

RGB display panels are used to display a wide range of televised events such as soccer matches or rock concerts, and are not only run at night. In the afternoon, the LEDs and the sunlight combine to add heat to the display. Good visibility can be maintained by either increasing the contrast ratio with low-reflective potting material or by increasing the forward current. With the first solution being costly, driving the LED at a higher current seems to be an attractive alternative.

A low thermal resistance enables the LED to be driven at a higher forward current in warm ambient conditions. For example, the ASMT-QTB0 can be driven at the maximum current of 50 mA for the red, and 30 mA for green and blue at 70°C ambient temperature. A conventional RGB PLCC-4 LED can only be driven at 25 mA (red) and 13 mA (green and blue) under the same ambient conditions. If the ambient temperature around the LED increases to 85°C, the red chip can still be driven at 35 mA, the green and blue at 22 mA. By comparison, conventional RGB PLCC-4 LEDs can only be driven at 15 mA or 8 mA respectively at such high ambient temperatures. This means that with a low thermal resistance LED, the brightness of the display will still be very high in warm environments. This also ensures good readability in sunlight or when a spotlight is pointing towards the display.

Product stability

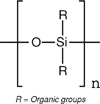

LEDs which will be used in outdoor full-colour signs must use robust packaging materials. For example, epoxy encapsulation is more sensitive to near-UV or UV radiation. Moreover, the blue emissions from the LED chip discolour the epoxy over time, which decreases the light output. A much better material to use for encapsulation is silicone. Silicone’s strong siloxane bond results in superb stability under heat, or near-UV and UV radiation. This enables long life performance of multi-colour or high-brightness LEDs with little intensity degradation. Additionally, silicone can be formulated with different hardness properties. For examples, silicone used in LEDs for full colour signs should be formulated elastic to absorb potential thermal stress in the application. This relaxation also helps to prolong the lifetime expectancy of the LED.

A lead frame dissipates a majority of the heat from the LED chip to the thermal pads on the PCB. Therefore, a highly thermally conductive material should be used as the base material in the lead frame. Ideally, the lead frame is made from copper, which has the best thermal conductivity factor (minimum 350 W/m*K) among any metals that are the currently available. Additional silver plating makes the soldering easier and inhibits the growth of tin whiskers in the later product.

Colours and colour mixing

In a full colour display, it is important to be able to display colours with high purity or saturation. This can only be achieved if the basic red, green and blue colours are highly saturated. For example, a very saturated blue (dominant wavelength ~465 nm) enables good colour mixing with green or red. This creates highly distinguished mixing colours with excellent saturation. Of course, the same approach also applies for red (dominant wavelength ~621 nm) and green (dominant wavelength ~528 nm).

In order to achieve a D65 white colour point, the ratio between red, green and blue is estimated to be approximately 3,5:8:1 for wavelengths of 621 nm, 528 nm and 470 nm. Different wavelengths will determine a different ratio. This means, if you have 200 mcd blue light, you need 700 mcd red and 1600 mcd green lights to generate a neutral white colour from RGB multicolour LEDs. The LED manufacturer can help the display manufacturer by pre-selecting the appropriate wavelength and intensity chips for use in the LEDs’ assembly.

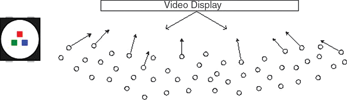

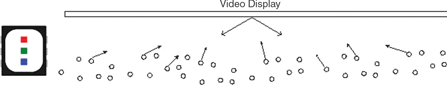

Depending on the installation and size of the display, it is important to choose the right internal dice arrangement. There are two types of arrangements available in the market: a triangular or 'star' arrangement of the chips, and an in-line or linear chip arrangement.

The 'star' chips’ positioning is especially favourable for centred screens with a 4:3 or 16:9 ratio, as this arrangement enables excellent light mixing and high colour uniformity from a wide range of viewing angles. People watching or passing the display within an angle of 120° will perceive the screen to be very uniform. The 'star' chip arrangement also makes the screen suitable for vertical viewing as well.

In-line chip positioning is recommended for screens such as U-TVs which can be found in soccer stadia across the world. These exceed the ratio of a conventional screen. Because these displays are very wide, but relatively small in the vertical direction, they are being viewed from directions which can easily exceed 120°. The linear placement of LEDs helps to ensure a uniform perception of the display and good colour mixing from wider horizontal viewing angles.

Assembling a display and soldering the LED components

It is recommended that designers of large displays follow the JEDEC guidelines when using surface mount (SMT) LED components. Display manufacturers that are accustomed to using through-hole LEDs before switching to SMT need to be especially careful, because SMT components are sensitive to moisture. The moisture sensitivity level (MSL) indicates how long the LEDs can be exposed to a factory controlled environment prior to soldering without the risk of moisture ingress. Moisture trapped inside the LED will vaporise immediately during reflow soldering. This can cause the chip or the bond stitch to lift from the lead frame, leading to a broken mechanical or electrical connection. This effect is called 'delamination' and can lead to field failures of an LED display.

For example, Avago’s PLCC-6 ASMT-YTB0 has an MSL rating of 2a. This means four weeks floor life with the ambient conditions maintained at a temperature below 30°C and a relative humidity below 60%. As outlined in JEDEC J-STD-033B, the floor life of SMT components with a thickness below 2,1 mm will decrease from four weeks to one day if the relative humidity is increased by only 10% (to 70%) at a temperature of 30°C. Therefore, it is important to carefully control the ambient conditions of the production line during both day and night in order to avoid failures in the display. If an LED has been exposed to unknown ambient conditions, it is recommended that it is baked on the reel at 60°C ±5°C for 20 hours. This will eliminate all moisture from the inside of the LED, and ensure that they can be soldered with the recommended soldering profile.

For more information contact Thami Moitoi, Arrow Altech Distribution, +27 (0)11 923 9600, [email protected], www.arrow.altech.co.za

| Tel: | +27 11 923 9600 |

| Email: | [email protected] |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

© Technews Publishing (Pty) Ltd | All Rights Reserved