In industrial nations up to half or more of all electrical energy is consumed by electric motors. They account for two-thirds of industrial electricity consumption and about one-fourth of residential electric use. Therefore, improving the efficiency of electric motors can significantly save energy and reduce operating costs.

Because of this, energy efficiency should be a major consideration when designing a motor drive, over and above price concerns. Now, a new generation of microcontrollers enables the energy efficient control of brushless DC motors (BLDC), permanent magnet synchronous AC motors (PMSM) and AC induction motors and contributes to the overall reduction of energy consumption.

The cost of ownership of an electric motor mainly consists of electricity costs. Over a motor’s lifetime electricity is more than 90% of its total cost, far outweighing the original purchase price and maintenance costs. According to the US Department of Energy (DOE), using a motor with about 4% to 6% higher efficiency rating can pay for itself in just two years, if the motor is in operation for more than 4000 hours a year. Given these factors, it makes sense to optimise the drive controller and/or algorithms.

As stated previously, in a typical industrial facility, electrical motors are responsible for approximately two-thirds of the total electrical energy consumption. To improve the efficiency and lower the operating costs of the electric motors, certain factors need to be considered. The major factors are:

* Selecting a high efficiency motor.

* Selecting the right size of motor.

* Selecting the appropriate motor technology.

* Using appropriate control algorithms.

Efficiency drops dramatically when motors are operated below 40% of full rated load. Therefore the right size of motor is important to reduce operating costs. Motors should be sized to operate with a load factor between 65% and 100%. The common practice of over-sizing results in less efficient motor operation.

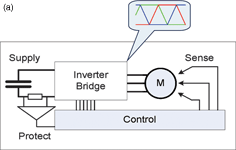

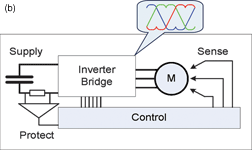

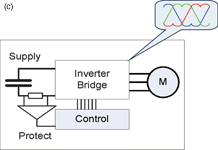

Various motor technologies like brushed DC motors, brushless DC motors, stepper motors or AC induction motors offer different benefits on purchase costs, control design, operating costs and energy efficiency. The type of motor control (Figure 1) used for the application has a big impact on energy efficiency. For low-power applications, stepper motors and brushed DC motors are popular due to their low purchase price and simple control circuitry, but they provide somewhat lower energy efficiency and, therefore, higher operating costs. The usage of BLDC, PMSM or AC induction motors, combined with powerful motor control algorithms running on optimised microcontrollers, offer the most energy efficient solutions. For brushless motors, a wide range of motor control system algorithms – including trapezoidal, sinusoidal, and field oriented control (FOC) – are available.

Block commutation

The simplest but lowest-performance method of motor control is trapezoidal control or block commutation, also known as six-step control (Figure 1a). For each of the six commutation steps, the motor drive provides a current path between two windings while leaving the third motor phase disconnected. This method has performance limitations in the form of torque ripple, which causes vibration, noise, mechanical wear and reduced servo performance.

Brushless motor control requires knowledge of the rotor position and mechanism to commutate the motor. Typically, Hall-effect sensors are used to provide absolute position sensing of the rotor. This results in more wires and higher cost. Sensorless BLDC control eliminates the need for Hall sensors, using the back-EMF of the motor instead to estimate the rotor position. Sensorless control is essential for low-cost variable speed applications such as fans and pumps. Refrigerator and airconditioning compressors also require sensorless control when using BLDC motors.

Sinusoidal control

Sinusoidal control, also known as voltage-over-frequency (V/f) commutation, eliminates some of the issues with block commutation (Figure 1b). A sinusoidal controller drives the three motor windings with currents that vary smoothly. This eliminates the torque ripple issues and offers smooth rotation. The fundamental weakness of sinusoidal commutation, however, is that it attempts to control time-varying motor currents using a basic proportional-integral (PI) control algorithm and does not account for interactions between the phases. As a result, interaction between the phases causes performance loss at high speeds.

Field oriented control

Sinusoidal commutation produces smooth motion at slow speeds, but is inefficient at high speeds. Block commutation can be relatively efficient at high speeds, but causes torque ripple at slow speeds. This leads to FOC, which provides the best of both worlds (Figure 1c). Using FOC, the efficiency of an electrical motor can be increased by up to 95%, providing less power consumption, less noise and excellent torque dynamics. This results in better efficiency of the inverter, a smaller power stage and smaller motor dimensions at the same torque.

The FOC algorithm works by removing time and speed dependencies and allowing the direct and independent control of both magnetic flux and torque. This is done by mathematically transforming the electrical state of the motor into a two-coordinate time-invariant rotating frame using mathematical formulas known as the Clarke and Park transformations. FOC can be used on both AC induction and brushless DC motors to improve their efficiency and performance. It can be applied also to existing motors by upgrading the control system.

All ingredients for energy efficient motor control

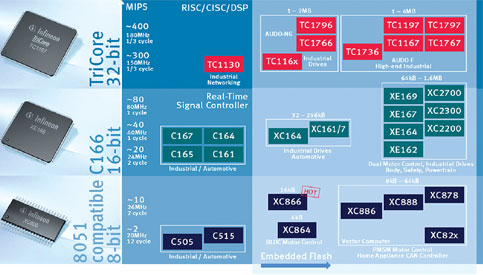

The effective implementation and execution of innovative motor control concepts needs an optimised microcontroller architecture and easy to use tools. Infineon not only offers powerful microcontrollers with 8-, 16- or 32-bit power (Figure 2), but also provides complete solutions with the related tool chain. In addition, a broad portfolio of application kits, which ease the evaluation and implementation of hardware and software solutions for highly efficient motor drives, is available. Depending on the application, a complete range of MCUs with 8-, 16- and 32-bit performance up to 400 MIPS is available.

The XC800 MCUs are based on the popular 8051 processor. It offers scalable solutions with 4 KB to 64 KB Flash memory, high-speed 10-bit ADC, PWM unit and packages with 20 to 64 pins. In addition the XC886, XC878 and XC888 series are equipped with a 16-bit vector computer supporting FOC. Using the vector computer, only about half of the CPU performance is needed to implement FOC. The XC800 MCUs are ideal for low-end drives in fans, pumps, appliances, airconditioners, etc.

The realtime signal controllers (RTSCs) of the XE166 family are built around an enhanced C166S V2 core. High CPU performance with up to 100 MIPS, a MAC unit for DSP functions, enhanced IO capabilities, flexible power management and new peripherals such as universal serial interface (USIC) make the XE166 devices suitable for demanding industrial applications such as motor control, power supplies, transportation and communication. With features like standard FOC support, dual motor control, dynamic load response and zero speed control, the XE166 family is ideal for use in inverters, servo drives, escalators or forklifts.

At the upper end, the 32-bit devices TC1167 and TC1197 focus on the most demanding industrial drives and offer high performance for motion control, such as multi-axis systems.

Application kits: Scalable motor control solutions

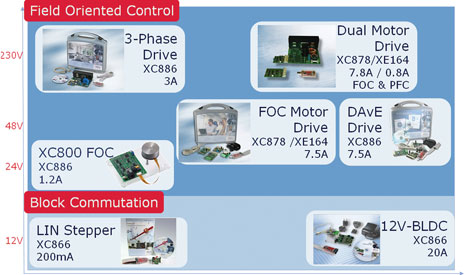

The available application kits and tool chain support the fast implementation of new motor control techniques on the microcontrollers. A complete portfolio of reference systems for motor drive applications is available supporting the whole range of algorithms, from block commutation to FOC (Figure 3).

All application kits contain a free tool chain (compiler, realtime debugging environment, etc,) and offer plug-and-play design, as all related hardware and software parts are provided. A complete solution with microcontrollers, power semiconductors and passive components is provided. Comprehensive documentation with hardware design examples is included with the application kits, serving a voltage range from 12 V to 230 V and drive currents from 200 mA to 20 A for stepper, BLDC and PMSM motors.

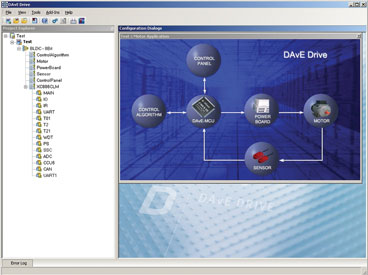

The kits are ready to be used with DAvE Drive (Figure 4), a unique auto code generator for motor drives. DAvE Drive is an application code generator available for the company’s 8-bit MCU families – support for XE166 is under development. It helps to reduce the software development time for motor drives due to fast and easy configuration of complex control algorithms like FOC. Designers of motor controls can quickly focus on application-specific software, such as the programming of drive functions. The DAvE Drive software tool generates complete algorithms with documented source code and does not derive from precompiled libraries. It also enables fast adaption for customer specific motors. The motor type can be selected from a library or defined by setting the key characteristics such as nominal voltage, phase inductance or resistance.

For more information contact EBV Electrolink, +27 (0)21 402 1940, [email protected], www.ebv.com, Electrocomp, +27 (0)11 458 9000, [email protected], www.electrocomp.co.za

| Tel: | +27 11 236 1900 |

| Email: | [email protected] |

| www: | www.ebv.com |

| Articles: | More information and articles about EBV Electrolink |

| Tel: | +27 11 458 9000 |

| Email: | [email protected] |

| www: | www.electrocomp.co.za |

| Articles: | More information and articles about Electrocomp |

© Technews Publishing (Pty) Ltd | All Rights Reserved