Electronics packaging systems for the housing of electronic components must satisfy a wide range of requirements, from accommodating printed circuit boards to containing complete systems, and are realised in various physical forms (see Figure 1) such as cabinets for indoor or outdoor use, as portable cases for mobile applications or for stationary use in a desktop enclosure, or as a case for mounting in a cabinet or wall-mounted enclosure.

Various environmental conditions may demand sealing against splash water, optimised cooling options, EMC shielding and much more. The user must pay due attention to these fundamental requirements in selecting the appropriate electronics ‘packaging’ for a given application.

What has to be packaged and where should it be positioned? These questions can only be answered by the user and are the starting point from which the particular requirements for a suitable electronics packaging can be evaluated.

Specifying packaging dimensions

The dimensions of the electronics packaging are governed, on the one hand, from the size and type of the electronics component groups themselves, and on the other, by any applicable guidelines or restrictions related to the location in which the system is to be used. If the components are primarily non-standardised, such as non-standard PCBs, then non-standard enclosures are used, at least with regard to the interior construction. If the electronic component groups are not too large, a suitable container is the so-called frame-type plug-in unit – a relatively compact unit that can in turn be mounted in standardised subracks or cases. In their exterior dimensions, frame-type plug-in units are 19-inch compatible and can accommodate both standard and non-standard components.

It is always advisable to make use of standardised components, eg, those compatible with the 19-inch standard, as there are a large number of solutions available for these on the market. Use of standard products saves the user development time, tool costs and the need to warehouse special components. Where the electronics sub-assemblies and components are larger, subracks, cases or cabinets can provide suitable packaging. In most of these, various accessory parts also provide the option of mounting non-standard assemblies. If the components to be accommodated are themselves 19-inch-compatible, the situation is further simplified.

The final installation location also has a bearing on the dimensions of the packaging. Often the available space is very limited, eg, on ships or other vehicles or even in data centres, such that specific guidelines must be observed. These boundary conditions can then create the first specifications and options relevant to the construction system being used. Mounting of electronics components can thus be in the form of:

* A frame-type plug-in unit in a subrack or case.

* Directly in a subrack or a case.

* A portable case.

* A desktop enclosure.

* A case mounted within a cabinet.

* A wall-mounted enclosure.

* A cabinet.

Standards and specifications

Depending on the area of application of the electronics, international and/or market specific standards and specifications must be observed. Current electronics packaging standards include standard dimensions supplements (IEC 60297-1, IEC 60297-2, IEC 60297-3-101, IEC 60297-3-102, IEC 60297-3-103, IEC 61969-2-1, IEC 61969-2-2, IEC 60917-2-X) and – at a higher level - criteria for physical integration (IEC 61587-1, IEC 61969-3), earthquake resistance (IEC 61587-2), electromagnetic compatibility (IEC 61587-3) and thermal management (IEC 62194 Ed.1).

The ETS standards are set by ETSI (European Telecommunication Standards Institute) for telecommunications systems in Europe. ETS standards are closely tied to the IEC standards with particular reference to telecommunications systems.

In addition to the IEC standards are specifications for applications that are necessary in certain market segments. Examples are VME from VITA (VME International Trade Association) or CompactPCI, MicroTCA and AdvancedTCA from PICMG (PCI International Computer Manufacturing Group). Moreover, there are special standards for applications in railway and military technology such as special welding specifications (IEC 60297) and environmental tests (EN 50155) for railway technology, shock and vibration tests (MIL 901D) (Figure 2) for maritime applications, etc.

Special safety and protection standards must also be observed. All conductive parts of a mechanical enclosure that come into contact with dangerous voltages must be earthed and tested to IEC 61010-1. The mechanical parts of a system must be free of sharp edges to prevent injury. Assemblies that generate heat and are accessible by the user must be covered or shielded. The materials and construction of the enclosure system must also be chosen in such a way as to prevent the spread of fire.

Plastics should conform to class V 2 (or better) for self-extinguishing materials, tested to IEC 60707. ISO 14000 must be observed in regard to the toxic additives found in materials of the higher self-extinguishing classes. The covering of a construction system must be so designed that flammable material cannot drip into other areas such as a cabinet. IEC 60950 specifies eg, the design requirements for ventilation holes on the underside of a cover.

IEC 60529 sets out the degree of IP protection for cabinets and cases against the entry of dust and water, and also the protection of persons from dangers in the enclosure. The IP grade consists of two digits: the first indicates the protection against foreign bodies (from inserted fingers through to the entry of dust); the second gives the protection against entry of water.

The multitude of considerations may seem complicated and confusing but need not be so – this hurdle can easily be overcome by using a competent electronics packaging partner. The user’s task is to describe the area of application of the electronics in as much detail as possible, and the electronics packaging specialist will handle the rest. It is important that the specialist be involved in the project from the early planning stage in order that the best and most cost-effective solution can be worked out.

Static and dynamic loading

Static loads arise primarily from the weight of the housed components. Factors affecting this include the material used in the construction (steel plate, aluminium, plastic), whether this is glued, welded, bolted or formed of a single piece, and the extent to which a weight-optimised design is possible. Depending on the application, eg, for railway applications, it may be necessary for suitable extra reinforcement or stiffening to be allowed for.

Also significant here is whether the system will be moved and repositioned or whether it is specifically designed for mobile use. If the system is to be transported to the installation location fully assembled, allowance is normally also made for variable dynamic loads. Such shock and vibration influences must also be taken into account for certain installation locations, such as near to rotating machines, in railway or transport applications and on ships and aircraft. If the application location is situated in an earthquake zone, the appropriate seismic testing must in all cases be performed beforehand.

Electromagnetic shielding

Requirements for electronic devices concerning EMC shielding vary according to the application and the environment in which it is located. This issue does not only concern high-frequency aspects. Shielding starts with the topic of ESD and extends through low-frequency capacitive or inductive coupling and mains-frequency interference up to high-frequency interference from electromagnetic radiation. Side, top and base parts, plus rear and front elements of cases and cabinets, are thus conductively linked to one another all round with a conductive surface (passivated or similar) and also with contact materials such as stainless steel spring seals or textile EMC gaskets. Even every cable entry must be appropriately protected.

Whether or not the steps taken for EMC sealing satisfy the appropriate requirements can be verified by means of the standardised EMC tests (VG95373 part 15)(Figure 3). In this area Schroff works together with independent, certified laboratories. The environmental standard IEC 61587 also defines tests for the EMC behaviour of cabinets, cases and subracks. Part 3 of IEC 61587 defines the test conditions for empty cabinets and subracks in terms of their EMC shielding characteristics in a frequency range from 30 Hz to 1 GHz and the required attenuation values. Here the standard relates primarily to IEC 60297 and IEC 60917.

The definition of various shielding efficiencies should also facilitate the choice by the user of the appropriate construction system on the basis of reference values. It must be borne in mind that this standard is restricted solely to the mechanics for electronic devices; it does not apply to the electronic devices themselves. Other standards apply to the end products. In normal cases, the test procedures required for these differ substantially from those described in the above standards. These tests are usually carried out by the manufacturer of the finished system or by testing laboratories contracted for the purpose. Different levels of shielding can be achieved depending on the type of cabinet, case or subrack construction.

In order to establish the necessary level of shielding, it is necessary to determine not only the critical interference frequencies emitted by the installed electronics, but also the frequencies of interference received from outside that may affect the enclosed electronics.

Temperature conditions

To assure the functional reliability and dependability of a system, it is necessary, among other things, to extract the heat generated by the active components housed in the cabinet or case. In most cases, the type of cooling is selected on the basis of two criteria: the magnitude of the dissipated heat and the installation location.

In airconditioned rooms, the electronics cabinets used are mostly open, air-cooled units. Where the waste heat is greater, external fans are added to those of the components themselves, which may be eg, chassis fans, pusher fans, air-filtered fans or air/air heat exchangers (AAHE). Depending on the type of this supporting air cooling, the cabinets must be partially or fully closed, as in the case of air-filtered fans or an AAHE. Wherever the temperature of the surrounding air is insufficient to maintain the required temperature in the required location, however, further cooling is effected with either an airconditioner unit or water cooling.

An optimised air cooling system is normally sufficient for subracks and cases. For more complex VMEbus, CompactPCI, MicroTCA and AdvancedTCA systems, guidelines are also provided in their respective specifications. Schroff develops and manufactures its own cooling solutions in line with these guidelines.

Often helpful, and increasingly necessary, is a thermal simulation of the heat generation and the effect of the heat in a cabinet or case, using purpose-designed software (Figure 4). In the hands of an experienced specialist, the software provides results that allow an optimal cooling design as well as the best use of the available space. The professional design of an electronics system therefore assumes that a specialist in these calculations is involved in the planning phase to advise the developer and to perform the calculations required.

Noise emission and sound insulation

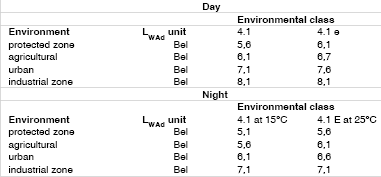

The possible noise exposure for employees (where the system is installed indoors) or residents (outdoor installation) close to the installation should not be underestimated. Therefore, particular attention must be paid to observing the relevant guidelines and regulations. These set limit values or benchmarks for noise levels for offices, workspaces and machines. The noise level should be kept as low as is technically possible. For office or laboratory environments the limits are from 40 to a maximum of 50 dB(A). For outdoor installations, standards such as ETS 300 753 (European Telecommunication Standard) (Table 1) determine the permissible limits.

Suitable measures for observing these regulations include, for example, the use of an intelligent algorithm to control the fan rotation speed where active air cooling is provided with air-filtered fans. This allows the system to stay within the noise level limits specified. Moreover, in Schroff designs, the fans are over-dimensioned, so that they do not have to run at full speed in order to provide the necessary air throughput, thus also keeping noise low. In the case of AAHEs and airconditioner units, special vibration insulation is employed to provide a high degree of mechanical decoupling from the cabinet. Where necessary, additional stiffening is added to the interior of the cabinet in order to convert any oscillation to a frequency that causes less of a disturbance.

Environmental considerations for outdoor installation

For outdoor installations, extremes of environmental conditions must also be borne in mind – such as sand, dust, insects, rodents, vandalism and vibration. It is also recommended that such installations avoid any visible screws or fixings, to prevent unauthorised access or tampering.

Similar in importance are the influences of cold, heat and direct sunlight. The matter of climate control is particularly important in outdoor situations: here not only must the heat generated by the components be dealt with, but also the effects of external influences (such as the time of year and time of day). For such installations, Schroff has developed cabinets eg, with a double-wall design. This concept provides a natural airflow between the outer and inner walls, thus requiring substantially less energy input for additional cooling. Heat gain from direct and reflected sunlight is avoided by up to 85%. Where external temperatures are very low, a heating unit is installed in the cabinet or case.

Environmental considerations for indoor installation

Indoor installation can be in a variety of settings, from office and laboratory environments to harsh situations in an industrial production facility. Important criteria here are the type of IP protection, EMC shielding, temperature and noise prevention. If the installation is in an office environment, temperature and noise prevention are the most important criteria. In removing waste heat it must be ensured that this is not exhausted into the room, as this would raise the room temperature. The noise level limits are also considerably lower in office settings than they are in, for example, industrial production.

In industrial installations, the removal of waste heat is of course important, but here IP protection and EMC shielding are of particular significance. Some machines and production systems can emit interference signals that may interfere with the functioning of the electronics in the cabinet or case if it is not sufficiently shielded. Simulations and tests performed during the course of project development in a packaging partner’s laboratories, such as heat simulation using Schroff’s Flotherm software, can shorten development time and give assurance between the individual development stages.

Visual aspects

The exterior design of electronics enclosures has become more important in recent years, even in industry. Schroff therefore offers a platform of cases that differ in their outward appearance but feature the same interfaces and/or internal mounting options. This ensures that the same off-the-shelf components from Schroff’s ‘construction kit’ can be used in any of them. Various exchangeable parts allow entire families of devices to be constructed – small cases, desktop enclosures or tower systems – with the same visual design. Different design variants are also available for cabinets. A wide selection of RAL colours (Figure 5), different surface treatments and printing options allow a customised, individual product to be created.

Integrating cabling, earthing, backplanes and power supply

Electronics packaging is more than merely the ‘packaging’ of the electronics, as users increasingly request that additional components be integrated into the package. With Schroff, this system integration includes the integration of electromechanical and electronic components such as EMC components, cabling, switches, backplanes, PSUs, monitoring devices and cooling solutions within a cabinet or case. Users thus obtain a kind of plug-and-play product for their 19-inch system. Schroff undertakes the entire project management and advises the customer from the initial specification and design through purchase, prototype manufacture, testing and checking through to actual product manufacture, including logistics and after-sales service.

Ease of assembly, transportation and packaging

The ease of assembly of a system is also of importance. Normally systems can be supplied either as kits or fully assembled. In all cases it is important to ensure that the system can be assembled simply (Figure 6), without requiring expensive special tools or demanding excessive time because the assembly instructions are unclear or complicated.

Also of increasing importance is customer support around the product, beginning with configuring and advising on the ordering and covering delivery and, finally, disposal. With Schroff, customers can create their individual product from a large pool of off-the-shelf components. Support is available for this via interactive online configurators.

Schroff supports and advises its customers throughout the entire product lifecycle: from delivery to recycling. This also includes services such as delivery to the point of use, commissioning, warranty extensions, maintenance, repair, parts and modernising. And since Schroff places a high priority on responsibility towards the environment, the service is completed with an environmentally sustainable recycling process at the end of the product’s useful life.

| Tel: | +27 11 608 3001 |

| Email: | [email protected] |

| www: | www.actum.co.za |

| Articles: | More information and articles about Actum |

© Technews Publishing (Pty) Ltd | All Rights Reserved