When one has hundreds of different data acquisition devices to choose from on a wide variety of buses, it can be difficult to select the right bus for a specific application’s needs. This article examines the most common PC bus options available and outlines the technical considerations to keep in mind when choosing the right bus for a measurement application.

Five questions to ask when choosing the right bus

There are five questions to ask oneself when choosing the right bus:

1. How much data will be streaming across this bus?

2. What are the single-point I/O requirements?

3. Is it necessary to synchronise multiple devices?

4. How portable should this system be?

5. How far will the measurements be from the computer?

1. How much data will be streaming across this bus?

All PC buses have a limit to the amount of data that can be transferred in a certain period of time. This is known as the bus bandwidth, and is often specified in megabytes per second (MBps). If dynamic waveform measurements are important in an application, one should be sure to consider a bus with enough bandwidth.

Depending on the bus that is chosen, the total bandwidth can be shared among several devices or dedicated to certain devices. The PCI bus, for example, has a theoretical bandwidth of 132 MBps that is shared among all PCI devices in the computer. Buses that offer dedicated bandwidth, such as PCI Express and PXI Express, provide the maximum data throughput per device.

When taking waveform measurements, a certain sampling rate and resolution need to be achieved based on how fast the signal is changing. One can calculate the minimum required bandwidth by taking the number of Bytes per sample (rounded up to the next Byte), multiplied by the sampling speed, and then multiplied by the number of channels.

For example, a 16-bit device (2 Bytes), sampling at 4 MSps on four channels would require:

The bus bandwidth needs to be able to support the speed at which data is being acquired, and it is important to note that the actual system bandwidth will be lower than the theoretical bus limits. Actual observed bandwidth depends on the number of devices in a system and any additional bus traffic from overhead. If a lot of data needs to be streamed on a large number of channels, bandwidth may be the most important consideration when choosing the data acquisition bus.

2. What are the single-point I/O requirements?

Applications that require single-point reads and writes are often depending on I/O values to be updated immediately and consistently. Based on how bus architectures are implemented in both hardware and software, single-point I/O requirements could be the determining factor for the bus that is chosen.

Bus latency is the responsiveness of I/O. It is the time delay between when a driver software function is called and the actual hardware value of the I/O is updated. Depending on the bus chosen, this delay could range from less than a microsecond to a few milliseconds. In a PID control system, for example, this bus latency can directly impact the maximum speed of the control loop.

Another important factor in single-point I/O applications is determinism, which is a measure of how consistently I/O can execute on time. Buses that always have the same latency when communicating with I/O are more deterministic than buses that can vary their responsiveness. Determinism is important for control applications because it directly impacts the reliability of the control loop, and many control algorithms are designed with the expectation that the control loop will always execute at a constant rate. Any deviation from the expected rate will make the overall control system less effective and less reliable. Therefore, buses that are high in latency with poor determinism, such as USB, should be avoided when implementing closed-loop control applications.

The software side of how a communications bus is implemented plays a big part in bus latency and determinism. Buses and software drivers that have support for real-time operating systems will provide the best determinism and therefore give the highest performance. In general, internal buses such as PCI Express and PXI Express are better for low-latency single-point I/O applications than external buses such as USB or wireless.

3. Is it necessary to synchronise multiple devices?

Many measurement systems have complex synchronisation needs, whether it is synchronising hundreds of input channels or multiple types of instruments. A stimulus-response system, for example, might require the output channels to share the same sample clocks and start triggers as the input channels to correlate the I/O and better analyse the results. Data acquisition devices on different buses provide different ways of accomplishing this.

Almost all National Instruments data acquisition (DAQ) devices provide access to programmable function input (PFI) lines that can be used to route clocks and triggers between difference devices, and software support in NI-DAQmx to configure these lines. Certain buses, however, have additional timing and triggering lines built in to make multidevice synchronisation as easy as possible. PCI and PCI Express devices offer the real-time system integration (RTSI) bus, on which multiple boards in a desktop system can be cabled directly together inside the case. This removes the need for additional wiring through the front connector and simplifies I/O connectivity.

The best bus option for synchronising multiple devices is the PXI platform, including PXI and PXI Express. This open standard was specifically developed for high-performance synchronisation and triggering, with a number of different options for synchronising I/O modules within the same chassis, as well as synchronising multiple chassis.

4. How portable should this system be?

The dramatic adoption of portable computing is undeniable, and has offered engineers and scientists new ways to innovate with PC-based data acquisition. Portability is an important factor for many applications, and could easily be the primary reason to choose one bus over another. In-vehicle data acquisition applications, for example, benefit from hardware that is compact and easily transported.

External buses like USB and Ethernet are particularly good for portable data acquisition systems because of quick hardware installation and compatibility with laptop computers. Bus-powered USB devices provide additional convenience because they do not require a separate power supply to be present, and are powered off the USB port. Using wireless data transfer buses is another good option for portability, because the measurement hardware itself becomes portable, while the computer can remain stationary.

5. How far will the measurements be from the computer?

The distance between measurements and where the computer is located can drastically vary from application to application. To achieve the best signal integrity and measurement accuracy, one should place the data acquisition hardware as close to the signal source as possible. This can be a challenge for large distributed measurements like those used for structural health monitoring or environmental monitoring. Running long cables across a bridge or factory floor is costly and can result in noisy signals. One solution to this problem is to use a portable computing platform to move the entire system closer to the signal source. With wireless technology, the physical connection between the computer and the measurement hardware is removed all together, and distributed measurements can be taken and the data sent back to a central location.

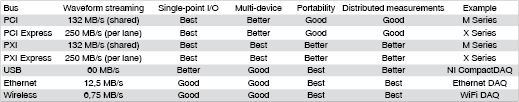

Based on these five questions, Table 1 shows a selection guide for the most common data acquisition buses available.

Overview of data acquisition buses

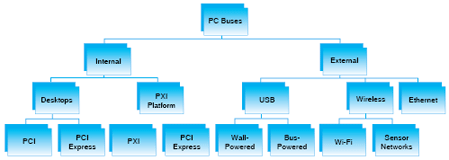

While there are many different buses and form factors to choose from, this section focuses on the seven most common buses, which are PCI, PCI Express, USB, PXI, PXI Express, Ethernet and Wireless. Figure 1 shows these buses organised into a PC-bus hierarchy of NI data acquisition products, from internal plug-in options to hot-swappable external buses.

PCI

The peripheral component interconnect (PCI) bus is one of the most commonly used internal computer buses today. With a shared bandwidth of 132 MBps, PCI offers high-speed data streaming and deterministic data transfer for single-point control applications. There are many different data acquisition hardware options for PCI, with multifunction I/O boards up to 10 MSps and up to 18-bit resolution.

PCI Express

PCI Express is an evolution of PCI and offers a new level of innovation in the PC industry. The single biggest benefit of PCI Express architecture is the dedicated bus bandwidth provided by independent data transfer lines. Unlike PCI, in which 132 MBps of bandwidth is shared among all devices, PCI Express uses independent data lanes that are each capable of data transfer up to 250 MBps.

The PCI Express bus is also scalable from a single x1 (pronounced 'by one') data lane to x16 data lanes for a maximum throughput of 4 GBps, enough to fill a 200 GB hard drive in less than a minute. For measurement applications, this means higher sustained sampling and data throughput rates, and multiple devices do not have to compete for time on the bus.

USB

The universal serial bus (USB) was originally designed to connect peripheral devices, such as keyboards and mice, with PCs. However, it has proven useful for many other applications, including measurement and automation. USB delivers an inexpensive and easy-to-use connection between data acquisition devices and PCs. Hi-Speed USB 2.0 has a maximum theoretical bandwidth of 60 MBps, which is shared among all devices connected to a single USB controller. USB devices are inherently latent and nondeterministic. This means that single point data transfers may not happen exactly when expected, and therefore USB is not recommended for closed-loop control applications such as PID.

On the other hand, the USB bus has several characteristics that make it easier to use than some traditional internal PC buses. Devices that connect using USB are hot pluggable, so they eliminate the need to shut down the PC to add or remove a device. The bus also has automatic device detection, meaning that users do not have to manually configure their device after plugging it in. Once the software drivers have been installed, the operating system should detect and install the device on its own.

PXI platform

PCI extensions for instrumentation (PXI) were developed to bridge the gap between desktop PC systems and high-end VXI and GPIB systems. The PXI Systems Alliance, with more than 200 members, maintains this open standard, and in 2006, passed the PXI Express specification to deliver PCI Express data transfer technology to the PXI platform.

Based on CompactPCI, PXI incorporates instrumentation extensions and more rigid system-level specifications to ensure an open yet high-performance specification for measurement and automation. The benefits of PXI-based data acquisition systems include rugged packaging that can withstand the harsh conditions that often exist in industrial applications. PXI systems also offer a modular architecture, which means that several devices can be fitted into the same space as a single standalone instrument, and one has the ability to expand a system far beyond the capacity of a desktop computer with a PCI bus. One of the most important benefits PXI offers is its integrated timing and triggering features. Without any external connections, multiple devices can be synchronised by using the internal buses resident on the backplane of a PXI chassis.

Ethernet

Ethernet is the backbone of almost every corporate network in the world and is therefore widely available. As a bus for data acquisition, Ethernet is ideal for taking portable or distributed measurements at distances beyond the 5 metre length of a USB cable. A single Ethernet cable can extend 100 metres before needing a hub, switch or repeater. This distance, in combination with a large installed base of networks in labs, offices and manufacturing facilities, makes Ethernet an ideal choice for distributing measurements to remote locations.

Though available network bandwidth is dependent on the number of networked devices, 100BASE-T (100 Mbps) Ethernet can accommodate multiple Ethernet data acquisition devices running at full speed. In addition, gigabit Ethernet (1000BASE-T) can aggregate data from multiple 100BASE-T networks for larger systems.

Wireless

Wireless technology extends the flexibility and portability of PC-based data acquisition to measurement applications where cables are inconvenient or impractical, such as wind farms or civil structures. Wireless can dramatically reduce costs by eliminating cables and installation time. However, wireless also has the highest latency of any data acquisition bus, so applications requiring high-speed control or determinism are not recommended. There are many different wireless technologies available, the most popular of which is IEEE 802.11 (Wi-Fi).

Wi-Fi is among the easiest of wireless technologies to set up. Connecting to a Wi-Fi ‘hotspot’ is as familiar to most as plugging in a USB cable. After 10 years of use in the IT sector, Wi-Fi is also secure. IEEE 802.11i (WPA2) is the highest commercially available wireless security standard to date with 128-bit AES encryption and IEEE 802.1X authentication. For streaming dynamic waveform signals, Wi-Fi provides more bandwidth than other wireless technologies, making it ideal for machine condition monitoring and other high-speed applications.

For more information contact National Instruments, 0800 203 199, [email protected], www.ni.com/southafrica

© Technews Publishing (Pty) Ltd | All Rights Reserved