One of the parameters of an isolated DC-DC converter is the range of the input voltage over which the converter can operate.

For the industry-standard ‘bricks’ available for the nominal 48 V input telecom marketplace, this range is usually 36 V to 75 V, or a ratio of about 2:1 from the highest to the lowest value. But there are many applications where a converter that can handle a much wider range of input voltage variation is desirable. For instance, in some systems the distributed input voltage has significant transients and surges that last too long to be removed by a filter.

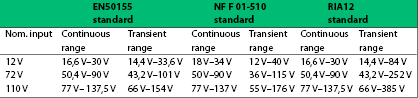

As one example, Table 1 shows the steady state and transient range of the distribution voltage that might be seen in various railway systems, as specified by the various agencies listed. Military and vehicle specifications have a similarly wide range over which their distribution voltages may vary. Another reason for using a DC-DC converter that can operate over a wide input voltage range is to create a ‘universal’ product that can be used in different DC systems. Instead of having to produce three different versions of a product to work off a nominal 36 V, 48 V and 72 V bus, a converter that could operate from 18 V to 135 V would permit a single solution, saving manufacturing costs and reducing inventory.

However desirable it might be to have a wide input converter, there is a major problem: in traditional products, the wider you make the operational input voltage range, the worse you make the converter’s performance. Generally, both the converter’s efficiency and the amount of power it can handle in a given size – such as a quarter-brick – is reduced.

This is the natural consequence of having to design for the highest input voltage while at the same time needing to handle the very large input current that results when the input voltage is at its lowest. For a converter that handles a 2:1 input range, the product of this maximum voltage and maximum current is twice that of the power being processed – a penalty, but one that can be accepted as a reasonable compromise. But in the case of a converter designed to handle an 8:1 input voltage range, the product is now eight times the processed power, and the penalty is extreme. This is most severely felt by the power circuitry associated with the isolation transformer of the converter.

Due to the aforementioned limitations, there are not many DC-DC converters commercially available to handle very wide range input voltages. The few ‘ultra-wide’ 4:1 input ratio converters that are available typically process less than one half the power in a given physical size compared to their counterparts that handle only a 2:1 input voltage range. In addition, their efficiencies are typically 10%-25% lower than 2:1 units.

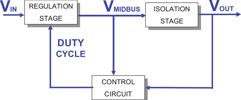

One way to mitigate this loss in performance in wide input range converters is to separate the converter’s regulation function from its isolation function, as shown in Figure 1. Here, the first stage of the converter is a non-isolated down-converter that provides regulation by varying its duty cycle. The second stage then provides electrical isolation (and typically a further step-down according to the turns ratio of the transformer) without any further regulation. This is how SynQor designs all its products.

The advantage of this two-stage design is that only the first stage sees the wide range of the input voltage. While a penalty for the wide range must be paid for by this first stage, it is not so severe because the first stage does not require an isolation transformer. The isolation stage, which does have the transformer, never experiences the wide input voltage range. In this two-stage design, the input voltage – the mid-bus voltage of the two-stage approach – is always constant. This permits the isolation stage to be optimised for a single operating condition, and it makes it much easier to implement a design based on synchronous rectifiers, which greatly reduces losses. The resulting increase of efficiency in the isolation stage goes a long way toward making up for any additional losses that occur in the regulation stage.

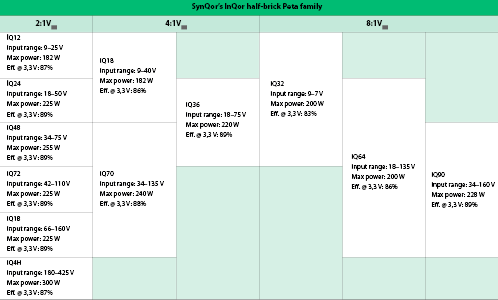

Figure 2 shows SynQor’s new IQ64 half-brick DC-DC converter with the super-wide 8:1 input range. The matrix in Table 2 shows the InQor converters and the various input voltage ranges for which they are designed. As can be seen, besides the normal 2:1 input ranges, there are products for 4:1 and even 8:1 ranges. The maximum power levels and typical efficiency for a 3,3 V output version are also shown in the figure. Although there is some reduction in power and efficiency as the input voltage range widens, it is not very significant. This is the result of the two-stage approach to the power circuit design.

In addition to handling the various input voltage ranges required, the SynQor line of InQor DC-DC converters are fully encased and ruggedised to handle the harsh environments that often accompany systems that have such challenging technical requirements.

For more information contact Conical Technologies, +27 (0)12 347 5035, [email protected], www.conical.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved