Recently, pick-and-place machines have expanded their applications to include complex dispensing tasks.

Such combined placement/dispensing machines can produce products at lower costs than individual specific machines. Previously, pneumatic dispensing valves mounted on SMT pick-and-place machines were just a useful accessory to save expensive stencils when producing prototypes. Today, the application range is much wider because modern SMT placement machines can also be combined with high-tech metering systems.

A state-of-the-art pick-and-place machine can be two to three machines in one: a component placer and up to two dispensing machines. Such a combination can reduce production cost: investment cost is less than half compared to individual machines, space and energy consumption is 60% less and maintenance is minimised. Further advantages result from the improved efficiency, including reduction of inventory cost and lower demand for consumables.

In a flexible production, there are often large differences in the utilisation of individual machines. Screen and stencil printers, for example, typically are not used for a significant amount of time. However, solder paste on the printer will spoil quickly because it is directly exposed to oxygen, temperature and humidity. Therefore, a printer should work continuously and possibly print a whole series at one time. As a result, there is a great need for storage areas for PCBs printed with solder paste. Additionally, the effort for cleaning and changeover of a printer are high. Using a dispensing system eliminates these challenges.

A dispensing valve is quickly prepared, cleaned and programmed. In addition, it can produce just-in-time which reduces the demand of storage space. Furthermore, the dispensing medium is sealed inside the cartridge, providing longer floor lifetime than paste on a printer. However, one of the great advantages of a dispenser compared to a printer is its flexibility: changeover requires no more than switching the program and cartridge.

Combined dispensing/pick-and-place machines are already used for many applications such as in the automotive industry, medical devices and even in the optical industry. In electronics manufacturing, many specific applications can only be solved using such machines, for example military applications where components are glued and soldered to withstand high G-forces. Another example, which will be seen more in the future, is the smart PCB.

Smart PCBs are compact and highly integrated, and protect sensitive components. In many cases, they can replace the housing because electronic components are mounted inside rather than outside the PCB. These components can be simple chips, ICs, flip chips or dies. They can be mounted into cavities of the PCB that are fully sealed. With a combined dispensing/placement machine, all required process steps can be done on a single platform: adhesive dispensing, component placement and the connection with conductive adhesive or the sealing of the cavity.

Another classic application for this type of machine is the manufacturing of membrane keyboards. Because flexible circuits are difficult to transport and even more difficult to store, a combined dispensing/placement machine with a vacuum table is an ideal solution. All production steps can be done without moving the foils: dispensing glue, placement and dispensing conductive glue. Furthermore, a UV lamp can be integrated to cure if UV adhesive is used.

The correct dispensing valve

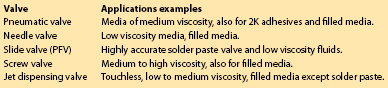

There are a number of dispensing valves adaptable to placement machines – see Table 1. Simple time/pressure valves can be combined with highly accurate, touchless jet valves, needle valves, screw valves, slider valves and more. Furthermore, there are heating and cooling options, spray valves, different dispensing needles and special valve versions.

Jet dispensing and piezo flow valves (PFV) are the most accurate solutions. The jet valve can shoot drops with a volume of only two nanolitres, while a PFV can create solder dots of only 100 µm diameter. If large volumes are required, for example for casting or for dispensing of LED lenses, screw, time/pressure or jet valves can be good solutions.

However, the selection should not be made without the help of an experienced specialist because the number of decision factors is high: the media to be dispensed, the required volumes, the final product and the surrounding conditions.

Limitations and outlook

An important principle to consider is that dispensing and placement processes are always serial on combined machines. On the one hand, this increases the utilisation of a machine, but on the other hand it limits the total production. Therefore, such solutions are less suited for high-volume production, but they are ideal for pilot lines, process and development laboratories, schools and universities, small series production and special applications.

A limitation imposed by the process may be the form of the dispensing dot which is always round or oval. For SMD applications, this may be limiting because soldering pads are normally rectangular and cannot be filled with solder paste to the edges. A printing process using stencils or screens can be more reliable because this process can force wetting of the complete pad.

Currently, development is ongoing towards 2- and 3D motion control of the dispensing head, which was not possible until now. The latest pick-and-place platforms such as the Paraquda from Essemtec will allow curve dispensing just like on specified dispensing machines. Therefore, the differences between a combined machine and single machines will narrow and this will allow more complex products to be produced on a single platform such as 3-D MID. The days when a dispenser was only a prototyping accessory on a pick-and-place machine have passed.

© Technews Publishing (Pty) Ltd | All Rights Reserved