With its new XMC1000 microcontroller family, Infineon is offering a 32-bit alternative for related 8-bit products, with significantly higher performance but for 8-bit prices.

The product family is based on the standard Cortex-M0 processor core from ARM, which has been specially designed for applications in the 8-bit market. By combining this processor core with extensive, dedicated peripheral functions, tools with high design productivity and production on the basis of state-of-the-art, cost-efficient process technology, Infineon is offering a genuine alternative for hitherto 8-bit users.

The trend towards replacing 8-bit microcontrollers with 32-bit MCUs is evident. According to market observers, for example, almost half of developers in German industry are planning to make this switch. The right price level has thus far been the limiting factor. Infineon is now catering to this situation with the introduction of the XMC1000 family.

The new products will be manufactured with an internal feature size of 65 nm and on 300 mm wafers. Customers who use a broad spectrum of microcontrollers also benefit from the fact that the XMC1000 is a genuine complement to the XMC4000 microcontroller family introduced in early 2012.

Numerous peripheral units such as timers, A/D converters and serial communication interfaces are identical in construction to those of the XMC4000 Cortex M4 products. This opens up numerous and diverse possibilities for scaling. For efficient software development, the development environment DAVE is available free of charge.

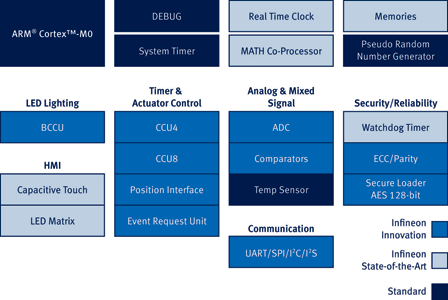

In addition to a number of the peripheral functions already known from the XMC4000 family, the XMC1000 derivatives offer features which, to date, were not found in 8-bit microcontrollers (Figure 1). A unique feature for this market segment is, for example, the range of Flash memory variants, which extend from 8 KB up to 200 KB.

In particular, special peripheral functions permit the professional and at the same time simple implementation of LED lighting applications and energy-efficient motor controls. With a solution concept for the IP protection of embedded software, Infineon is also picking up on an ever more important trend within the microcontroller market.

Three product series for various applications

The range of applications addressed by the XMC1000 family include such applications as motor controls, LED lights, digital power conversion, smart sensors, capacitive control elements and LED displays in addition to numerous other possible uses.

To this end, the new devices offer, besides the 32-bit Cortex-M0 with 32 MHz, numerous new features such as up to 200 KB Flash memory, powerful mixed-signal peripherals, modules for touch control and LED displays, a peripheral unit patented by Infineon for the dimming and colour control of LEDs, a Flash loader with 128-bit AES encryption for software IP protection and a MATH coprocessor with 64 MHz for efficient motor controls.

What is more, with such features as hardware error correction (ECC) and corresponding memory tests, the new microcontrollers satisfy the requirements defined by the IEC60730 class B standard, as prescribed for the safety of household appliances sold in Europe.

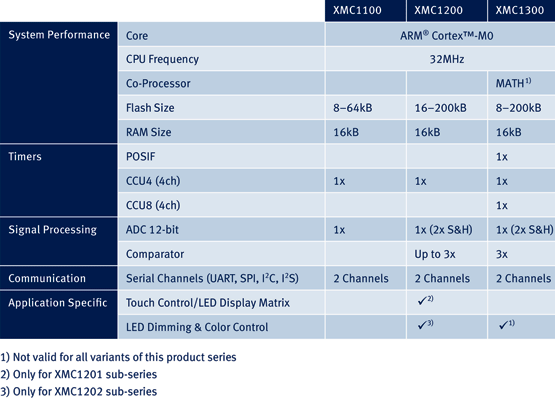

With three product series (Figure 2) and more than 20 products, each member of the XMC1000 family caters to different applications. By way of example, the XMC1100 Entry Series offers a basic range of functions to facilitate entry into the XMC world. Nonetheless, the features are state of the art, with 12-bit A/D converters and 16 bit timers which allow various PWM patterns to be generated.

The XMC1200 Feature Series comprises additional application-specific features, such as the above-mentioned peripheral unit for LED colour control and circuit units for capacitive touch control and LED displays. Furthermore, versions are available for the extended temperature range of -40°C up to 105°C.

Last but not least, the XMC1300 Control Series is specially geared to applications in the area of motor control and digital power conversion. To this end, besides the powerful Capture/Compare Unit 8 (CCU8), it also features, for example, a position interface (POSIF) for the precise detection of the motor position as well as a MATH coprocessor, which permits efficient sensorless FOC (field oriented control) solutions for electric motors – the latter being unique for Cortex-M0-based products. The XMC1300 family also offers variants for the temperature range up to 105°C.

Powerful, target-oriented peripherals

The XMC1000 family incorporates numerous powerful peripheral functions for a diverse range of industrial applications.

Key features are the CCU4 and CCU8 timer units. The Capture/Compare Unit 4 (CCU4) is important for systems that require efficient timers for signal monitoring and processing as well as PWM signal generation. This facilitates, for example, the implementation of switched-mode power supplies and UPS units.

The 16-bit timer modules consist of four identical, easily cascadable ‘timer slices’. This internal modularity of the timer unit permits software-friendly systems for rapid code development and simple porting. Each CCU4 timer slice can work in compare mode (one compare channel) or in capture mode (with up to four capture registers). In addition, the generation of up to four independent PWM signals is supported.

The CCU8 also supports applications with more complex PWM signal generation with complementary switches in half-bridge configuration, polyphase control and parity checking. This functionality, in conjunction with a highly versatile and programmable scheme for signal conditioning, means that the CCU8 is ideally suited for particularly powerful motor controls, polyphase and multi-level systems.

In compare mode, two compare channels are available for each timer slice. This allows up to four PWM signals to be generated per timer slice (up to 16 per CCU8 unit) with a delay in order to prevent short circuits in the switches. Each CCU8 module incorporates four service request lines, which can be programmed such that the timer acts as a synchronised trigger between the PWM signal generator and A/D converter.

The XMC1300MCUs also comprise positioning interface modules (POSIF) for supporting rotary transducers, Hall sensors and multi-channel position detection. The module is used for input filtering, edge detection and the control signals for the PWM unit. It can be configured for a diverse range of motor controls. This allows both simple and complex control loops to be realised with registration of the motor speed and position.

The LEDTS (LED and touch sense) modules provide a simple means of controlling LEDs and touch panels in HMI applications. Using the flexible USIC interface module, it is possible to implement various serial communication protocols such as ASC, SSC, I²C and I²S. A USIC module offers two independent communication channels. A dedicated FIFO permits buffering for slower applications.

The A/D converter module consists of a kernel that operates according to the principle of successive approximation (SAR). The resolution can be programmed with 8, 10 or 12 bits. What is more, the amplification can be set individually for each channel. A FIFO memory prevents data loss when working with very fast sampling rates.

The XMC1200/1300 series also integrate two sample-and-hold stages and high-speed analog comparators. Measurements with the A/D converters can be triggered by the CCU4/CCU8 timers. Other helpful peripheral functions include a pseudo random number generator, a real-time clock (RTC) and a window watchdog timer (WDT).

Innovative LED control

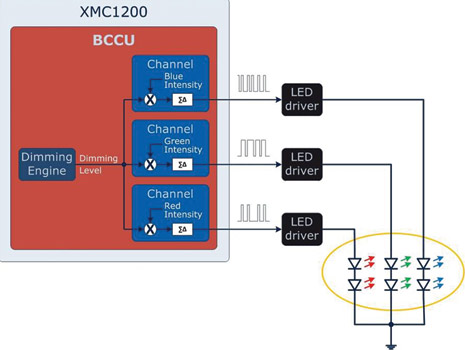

The XMC1200 and XMC1300 series feature a BCCU (brightness and colour control) unit. The basic function of the BCCU consists in automatically making dimming signals available at the port connections for external LED drivers (Figure 3). The BCCU is designed for automatically controlling the dimming and the colours of multi-channel LED lamps.

A key feature is the automatic high-frequency intensity modulation (PDM with 12-bit resolution) which permits a flicker-free display. The exponential dimming and linear adjustment of the intensity allow the dimming steps and colour changes to appear totally natural to the human eye. A wide range of high-performance LEDs is supported.

Using the two LEDTS modules of the XMC1200 family, it is possible, as mentioned, to drive LEDs and touch panels in HMI applications. At the same time, the LEDTS can measure the capacitance of up to eight touch pads each with the aid of an RO (relaxation oscillator) topology.

Up to 64 (8x8) LEDs can be controlled in one LED matrix and the modules can be synchronised with each other for optimised results. Touch pads and LEDs can share connections, which in turn minimises the number of pins required.

Energy-efficient motor control

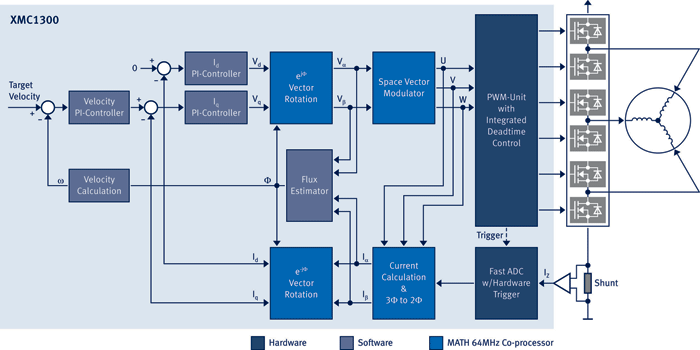

The CCU4/CCU8 timer units and POSIF position interface provide a simple means for ascertaining the position and speed of a motor for efficient motor controls. In addition, the MATH coprocessor can perform vector rotation (PARK transformation) with 24-bit resolution, which in turn allows powerful algorithms to be implemented for field oriented motor control (Figure 4).

The Capture/Compare Unit (CCU4) is primarily designed for switched-mode power supply applications. It can be used, for example, for pulse generation or, with the aid of the dither function, for stabilising slow control loops. In conjunction with the programmable POSIF block, it is also possible to evaluate an incremental encoder.

For various applications, using the POSIF allows the accuracy to be improved and the software simplified, since the corresponding data can be acquired at the same time. A low-pass filter suppresses the noise and interfering impulses from the Hall sensor and rotary transducer, which can otherwise lead to incorrect position and/or speed readings.

Using the CCU8 and the additional compare channel, it is possible to define different delays for rising and falling edges and to generate asymmetric PWM signals. Typical applications that benefit from this include 3-phase inverters for drives, 3-level inverters for solar modules and half-bridge converters.

The 64 MHz MATH coprocessor consists of a 32-bit scaler and a 24-bit CORDIC for trigonometric calculations. Both the scaler and the CORDIC unit can operate in parallel with the Cortex-M0 CPU. The MATH unit increases the processing power significantly for real-time applications.

IP security

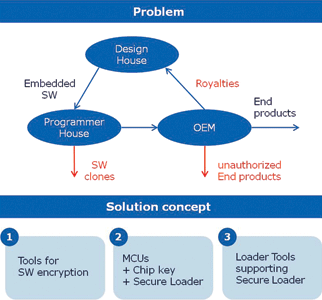

In terms of the development of microcontroller applications, specialisation and division of work is advancing. By way of example, corresponding data is increasingly exchanged between design companies for embedded software, service providers for serial programming and production and the OEMs of the finished products.

In this regard, there is always the risk of IP being spied on and, as such, for example, unauthorised copying and fraud when dealing with business models based on licence payments. In developing its new XMC1000 family, Infineon has addressed this ever more important aspect and has devised a concept for IP protection as illustrated in Figure 5. The company’s expertise from the field of chip cards also went into developing this.

Essentially, it is about ensuring that software can only run on specific microcontrollers and that only certain persons have access to the software code throughout the production process.

Infineon’s concept involves providing the IP owner with a tool that encrypts the embedded software, with a key that is only known to defined XMC1000 microcontrollers and, accordingly, which only permits programming on just these MCUs.

At the same time, the MCUs each carry customer and/or project-specific keys and execute a routine (secure loader mode, which is supported by the loader tool) that works on the basis of the 128-bit AES method and only encrypts the code during the loading process, which it saves to the Flash memory, before finally providing it with a lock protection facility.

Efficient development support

For efficient software development, in common with the XMC4000 series, the development environment DAVE is available, which can be downloaded free of charge from the Infineon website (www.infineon.com/dave). The tool package comprises an automatic code generator on the basis of DAVE Apps, a free GNU compiler and debugger, including Flash loader.

Furthermore, Infineon collaborates with numerous development partners who offer additional development tools such as compilers, debuggers, software analysis and Flash programmers in addition to software solutions, training and technical support for the XMC1000 family.

DAVE supports automatic code generation based on predefined and tested software components – otherwise known as ‘DAVE Apps’. In contrast to the conventional approach with libraries and sample programs, the DAVE Apps are more abstract and permit the simple graphic combination of multiple apps. This allows the hardware resources to be mapped automatically and accurately on the chip.

In conjunction with DAVE, corresponding DAVE Apps are available for downloading. These support, for example, Ethernet, data integrity and encryption solutions, PWM generation, various counter and timer application scenarios, interrupt handling and DMA (direct memory access) configuration. The apps are constantly updated and cater to a wide range of applications.

Since DAVE is an open platform, simple extension and adaption is possible. By way of example, users can work with their familiar design environment (IDE) and exploit the advantages of automatic code generation offered by DAVE without restrictions.

A simple evaluation facility for the new XMC1000 products is offered by what are known as boot kits, which are available for each of the three product series. In conjunction with DAVE, a debugger and a number of sample apps, they provide a complete package for the development of simpler application software.

For an application-oriented approach, Infineon provides dedicated application kits. For XMC1000, a kit will initially be available for the development of LED lighting solutions as well as one for standard and highly efficient motor controls.

For more information contact Davis Moodley, Infineon Technologies, +27 (0)11 706 6099, www.infineon.com

© Technews Publishing (Pty) Ltd | All Rights Reserved