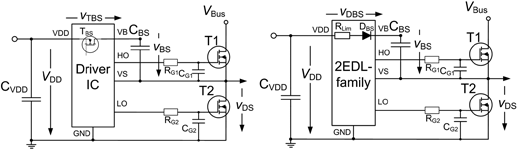

Only a few half bridge driver ICs currently available offer an integrated bootstrap function for the high-side supply. More typically the integrated bootstrap functions are realised by high-voltage FET structures, which are very area consumptive.

This is shown on the left in Figure 1. The resulting on-state resistance of the FET is above 120 Ω and therefore quite high. On the other hand, the high on-state resistance causes a high voltage drop at low duty cycles and additionally high power dissipation in the IC.

However, the advantages of a powerful integrated bootstrap function are striking. Firstly, the layout gets simpler because of fewer components on the board. Secondly, fewer components of course need less PCB space. The bootstrapping components and tracks are high-voltage ones and a suitable creepage distance must be considered when routing these connections.

Finally, better placement of the driver IC is possible in terms of the distance to the gate terminal of the power transistor. This also keeps the switching EMI low and optimises the switching performance, hence the switching losses of the power transistor.

In consideration of these advantages, Infineon developed its new half-bridge EiceDRIVER IC family, which uses integrated diode structures to overcome the disadvantage of a high on-state resistance bootstrap FET. This article presents evaluation results as well as a thermal model which is derived out of the measurements.

Thermal behaviour in application

Test setup

The application self-heating behaviour combines the static and dynamic losses of the driver IC. These are:

* Gate charge Qg of the driven power transistor including external gate-emitter capacitance CG according to Figure 1.

* Junction capacitance between high side and low side (CHL).

* Reverse recovery losses of the bootstrap diode (Erec).

* Resistive losses of the current limiting resistor (PRLim).

* Quiescent losses of the IC caused by the supply.

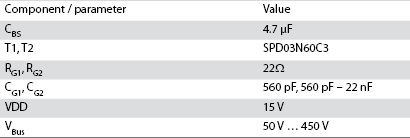

The test setup is defined on the right side of Figure 1. An infrared camera continuously measures the surface temperature of the device under test and communicates with a PC. The evaluation of the thermal performance of the 2EDL EiceDRIVER Compact family was performed using a 2EDL05I06PF device. The values of the test circuit are given in Table 1.

The external gate source capacitors are chosen in order to obtain an approximate total gate capacitance of 1 nF. Two measurements with 10 kHz and 200 kHz were performed in order to evaluate the self-heating effect as a function of the DC link voltage VBus.

Additionally, it is proven by measurement that the device temperature scales linearly with the switching frequency. A third measurement shows the IC temperature depending on the external gate-source capacitance.

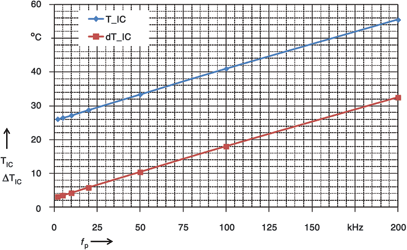

Influence of switching frequency fP

The blue curve in Figure 2 shows the absolute temperature TIC of the device surface, while the red curve shows the relative temperature increase ΔTIC above ambient temperature. The lines are strictly linear, which proves the linear dependency of the power dissipation on the switching frequency. It gives a simplification for the thermal modelling further below.

The temperature increase of the EiceDRIVER IC operating at 200 kHz is excellent at around 31°C. This measurement shows that the IC is capable of supporting modern switch mode power supply technologies.

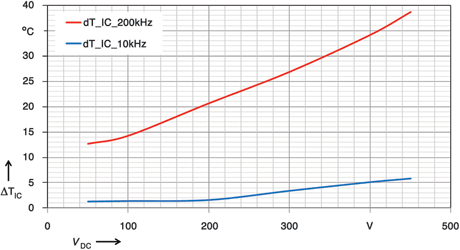

Influence of DC bus voltage

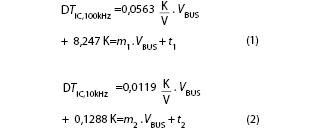

Figure 3 shows the relative temperature increase relative to DC link voltage variation of the IC at two different switching frequencies. The linear approximations are given by these equations:

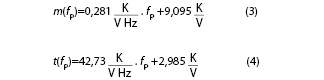

The total influence of switching frequency and the bus voltage can be extracted by deriving a linear function for m = m(fP) and t = t(fP) by using m1, t1, m2 and t2:

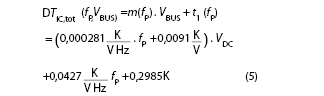

Combining equations 1 – 4 results then in the final thermal model depending on the bus voltage VBus and the switching frequency fP:

where the switching frequency fP is given in kHz.

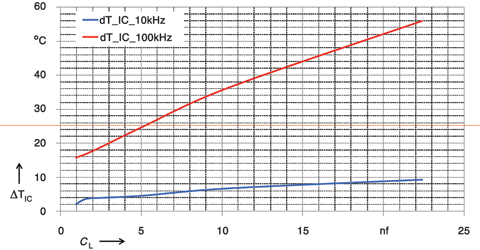

Influence of gate capacitance Cgs.

A third measurement evaluates the dependence of the IC temperature on the gate load. This was achieved by adding higher values for the external gate-source capacitance Cgs. The switching frequency was set to 100 kHz and the bus voltage to 300 V. The IC temperature can be approximated as a linear function of the gate load, as shown in Figure 4.

For more information contact Davis Moodley, Infineon Technologies, +27 (0)11 706 6099, www.infineon.com

© Technews Publishing (Pty) Ltd | All Rights Reserved