Automation engineers face new challenges as their tasks become ever more complex. Expectations regarding productivity, profitability, flexibility and the length of innovation cycles are becoming higher.

Furthermore, demands for ever lower power consumption are growing as productivity rises.

For the field and control level, this means efficiency-optimised drives with intelligent controls are needed. As central control units, microcontrollers play a key role in meeting these requirements.

Thanks to its configurability and high degree of software reusability, Infineon Technologies’ XMC4000 family is suitable for a wide range of different industrial applications: electric drives, solar inverters as well as production and building automation.

The five series in the XMC4000 family differ mainly in core frequency, memory capacity, peripheral functions and number of I/Os. The new ‘small brothers’ of the XMC4500 control modules further offer a high-resolution PWM unit for resolutions extending beyond the pulses lying within the CPU clock grid.

Due to their favourable properties regarding dynamic response, positioning accuracy and overload capacity, servo drives are increasingly being used for many applications. Microcontrollers play a central role in their implementation as they are the key component for control of the motors.

For these tasks, all XMC4000 controllers offer timer/PWM units (capture/compare unit or CCU) for signal monitoring and PWM generation. CCU4 is the basic implementation which is extended in terms of advanced features to CCU8. Their identical, modular assembly allows replication of the software and enables reusability in one and the same application or between different applications.

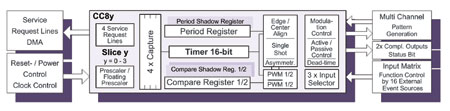

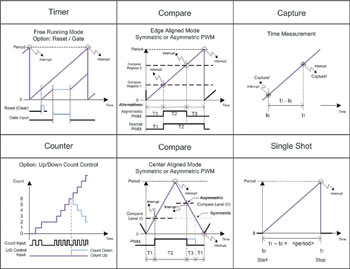

The CCU4/CCU8 module consists of four identical 16-bit time slices. Every slice can be operated in compare or capture mode. The CCU4 has one compare channel available and the CCU8 two. Up to four registers can be used in parallel in capture mode.

Every time slice can generate seven events, which can be assigned to four service request lines. A dedicated output works as PWM signal so that one CCU4 (CCU8) can generate up to 4 (8) separate PWM signals. The CCU8 slices additionally have an independent dead time unit for every output with different times for rising and falling edges (Figure 1).

Every timer slice can work in one of the available modes independently of the other slices. Events at the inputs of the slices are assigned to a certain action via a selection procedure (programmable matrix). This flexible assignment of input signals to desired reactions at the output enables true hardware/software co-design: the wiring on hardware level can be realised without knowing the final specification of the software. In addition to this, multiple slices can be interconnected to each other, thus enabling timer operations either 16, 32, 48 or 64 bits wide (Figure 2).

Exact positioning by rotary encoder

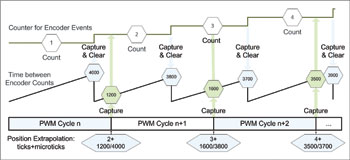

All XMC4000 family members have at least one so-called position interface (POSIF) available for motor control applications. Together with the timer units, the POSIF enables optimum use of rotary encoders such as quadrature encoders or Hall sensors. The timer units count and record the decoded POSIF events simultaneously.

Considering the change in these values over a period of time, it is possible to extrapolate the next rotor position or speed change. This has two benefits: the asynchronous encoder events are synchronised in the control loop and, through extrapolation, have a constant resolution. This improves the quality of control, especially in the case of wide dynamic speed ranges (Figure 3).

High-resolution PWM for digital power control

The high-resolution PWM unit is an extension to the XMC4000 derivatives XMC4400, XMC4200 and XMC4100. This extension is aimed at a variety of applications in the field of digital power conversion. A wide range of circuit topologies (e.g. boost converter, buck converter, forward converter, flyback converter and resonant converter), modulation modes (continuous or discontinuous PWM, phase shifter) and control methods (average or peak current or voltage control) is available for selection.

The advantages of digital control over analog control lie mainly in its easy adaptability. For example, various operating modes and control parameters can be changed dynamically per software. Ageing of passive components and parasitic effects can also be adapted without hardware intervention.

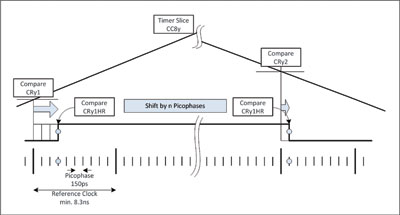

However, digital control has problems with quantisation effects and seldom achieves the quality of an analog variant. This disadvantage is minimised by the high-resolution pulse width modulation unit (HRPWM) of the XMC44/42/41xx modules. A so-called high-resolution channel (HRC) has a step width (pico phase) of only 150 ps.

The following example illustrates the benefit: a conventional timer resolves a 200 kHz buck converter in 20% partial load range with only 6 - 7 bits, presuming a system frequency of 120 MHz (calculation: 20% of 120 MHz/200 kHz = 120 values). Considering that the control variable is captured by an A/D converter with a resolution of 12 bits (20% of 2048 = 410 values), the rough PWM step width limits control.

Using an HRC, a resolution of 12 - 13 bits is obtained with the same calculation, i.e. no limitation of control by the PWM. Up to four HRCs with their own dead time control are implemented on the XMC44/42/41xx and can be connected downstream of the capture/compare units. This allows use of the complex control, trigger and switch-off logic of the CCU4/8. The modular and scalable assembly accommodates the multitude of circuit topologies used (Figure 4).

The second extension of the HRPWM unit is aimed at a further weak point of digital power control, namely its slow adjustment. If, in the above example of the boost converter, adjustment is to take place in every PWM cycle, this results in a not inconsiderable critical real-time CPU load.

However, a microcontroller is used in power control exactly where additional communication or actuator tasks are necessary. The extremely time-critical control of the boost converter must therefore run in the background and must not disturb the main application.

The so-called comparator and control signal generator block (CSG) helps here. This is a unit with a comparator that allows monitoring of the fast signals without CPU load and to actuate the corresponding circuit breaker. The comparator has numerous application-supporting properties on its input and output sides.

Thus the negative input can come from two selectable external signals (e.g. peak current and current zero crossing for control at discontinuous conduction mode limit). A fast digital/analog converter (30 MSamples at 10-bit resolution) controls the positive input. A filter and masking logic at the output of the comparator suppresses unwanted short pulses and a terminal logic ensures a defined state on switching on or off.

The peak current control known from the switching power supply world is enabled by a peculiarity of the D/A converter: it can autonomously generate a ramp whose offset and ramp time are programmable by the CPU. This prevents oscillation of this control method.

A CSG block consists of three comparators and three D/A converters and can be used independently or in interaction with the high-resolution PWM, the capture/compare units and the analog/digital converters. The CSG block manages the fast internal control loop autonomously and the CPU is then only responsible for the slow external control loop.

Here, again, the flexibility of the layout offers users a big advantage. Automation applications often need controlled auxiliary voltages with special properties that cannot be realised with off-the-shelf switching power supply ICs. Often there are special requirements regarding the switch-on/off behaviour, operating modes must be switched and safety aspects must be considered.

This is where the advantages of a programmable microcontroller come to bear. The integrated HRPWM unit on the new XMC4000 derivatives improves the resolution, quality and efficiency of digital power control significantly and closes the gap to the analog world.

For more information contact Davis Moodley, Infineon Technologies, +27 (0)11 706 6099, www.infineon.com

© Technews Publishing (Pty) Ltd | All Rights Reserved