Four reasons for X-ray inspection of surface mount devices

25 February 2015

Manufacturing / Production Technology, Hardware & Services

Vision inspection systems can find visible defects on PCBs, but these systems can only check the surface for errors, not the hidden solder joints of components like BGAs and flip chips. X-ray inspection can provide critical verification of the integrity of hidden solder joints on surface-mount devices.

Figure 1. Solder ball shorts.

The following are four of the most common examples of faults that X-ray inspection is best suited to detecting.

1. Solder ball shorts

Solder ball shorts, or solder bridges, can be easily detected with an X-ray image, as shown in Figure 1.

2. Solder ball voids

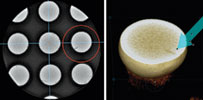

Figure 2. BGA void image with auto void calculation.

Ball-void inspection is used for BGA/CSP inspection along with solder ball bridge inspection.

Modern X-ray inspection systems can perform auto ball-void calculations (Figure 2).

Figure 3. BGA void location.

Not only is the size of the BGA voiding area important, the location of the BGA void is also important (see Figure 3), especially if the voiding area is close to the PCB pad area, because there is a possibility that this voiding area could cause a micro-crack.

Figure 4. Solder ball open.

3. Solder ball open / micro cold solder

Solder ball attachment to the PCB pad is a critical inspection criterion. A high-resolution and high-magnification X-ray inspection system is required to detect a solder ball open defect. The X-ray image in Figure 4 shows a solder-ball open where the copper pad is separated below the solder ball.

Figure 5. Solder ball open caused by small solder ball.

3D CT can assist with clear visualisation of open patterns. Figure 5 shows a solder ball open caused by the solder ball being too small. The image on the left shows a Y-Z slice image, indicating that the solder ball is smaller than the other ones. The image on the right shows an X-Y slice, indicating that the PCB pad (dark area) is not surrounded by a solder ball (white edges).

Figure 6. Cold solder – optical image.

Micro cold-solder joints can also be visualised with 3D CT, as illustrated in Figures 6 and 7.

Figure 7. Cold solder – non-destructive 3D CT image.

4. Solder ball crack

Using oblique CT technology, a solder ball crack can be visualised. Figure 8 shows a 10 micron solder ball crack.

Figure 8. Solder ball crack.

For more information contact Igmar Grewar, Quamba Technologies, +27 (0)83 417 4294, [email protected], www.quamba.co.za

Further reading:

20 years of precision, progress and purpose – the Jemstech journey

Jemstech

Editor's Choice Manufacturing / Production Technology, Hardware & Services

Twenty years ago, Jemstech began as a small, determined venture built on technical excellence and trust. Today, it stands among South Africa’s leading electronic manufacturing service providers.

Read more...

An argument to redefine IPC class definitions for class 1, 2, & 3 electronics

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

One of the most critical aspects of electronic assembly reliability is cleanliness. Contaminants left on a circuit board after the reflow process can lead to failures through mechanisms such as electrochemical migration or corrosion.

Read more...

Large platform stencil printer

Techmet

Manufacturing / Production Technology, Hardware & Services

GKG’s large platform stencil printer, the P-Primo, is designed to meet customer’s ultra-large printing requirements by supporting board dimensions up to 850 x 610 mm.

Read more...

Press-fit component inspection

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

In electronics manufacturing, optical inspection of press-fit components is crucial to ensure the quality, reliability, and performance of the final assembled product.

Read more...

A new era in wire bond inspection

Techmet

Editor's Choice Manufacturing / Production Technology, Hardware & Services

Viscom is developing a 3D wire bond inspection system that incorporates substantially improved sensors, a high image resolution, and fast image data processing.

Read more...

High-speed, high-resolution material deposition system

Manufacturing / Production Technology, Hardware & Services

ioTech recently unveiled the io600 inline digital laser material deposition system at productronica 2025.

Read more...

Mycronic’s MYPro A40 pick-and-place solution

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

Mycronic’s MYPro A40 pick-and-place solution, equipped with an MX7 high-speed mounthead technology, increases top placement speeds by 48% over the previous generation.

Read more...

Why ergonomics matters in digital microscopy

TANDM

Manufacturing / Production Technology, Hardware & Services

While magnification technology has kept pace with demand, the wellbeing of the people behind the microscopes has often been overlooked with technicians spending long hours in intense focus, leading to chronic strain, fatigue, and costly mistakes.

Read more...

From ER to effortless: The 15-year journey of Seven Labs Technology

Seven Labs Technology

Editor's Choice Manufacturing / Production Technology, Hardware & Services

What started as a business likened to an ‘ER’ for electronic components has today grown into a trusted partner delivering kitting services and full turnkey solutions – taking the effort out of electronics and helping customers truly ‘Move to Effortless.’

Read more...

Choosing the right electrical component supplier for reliability and scale

Rebound Electronics

Manufacturing / Production Technology, Hardware & Services

Selecting the right supplier extends beyond cost or delivery time; it is about ensuring long-term reliability, compliance, and scalability.

Read more...