Interest in cold plasma technology is growing across a wide range of industries, owing to the fact that it enables the surface properties of materials to be manipulated in a multitude of ways without causing damage or destruction, and it can be used to clean and disinfect surfaces and spaces.

As one of the four fundamental states of matter, plasma is formed when a gas is ionised. Plasma possesses conductive properties that are similar to those of metals and depend on the input parameters such as energy, pressure, process gas composition, and the addition of primer substances.

Plasma treatment is already implemented in numerous applications in almost all industrial branches. For an increasing amount of these applications a cold (non-thermal) atmospheric pressure plasma is required – especially in both industrial and healthcare applications such as surface treatment, cleaning, disinfection and odour reduction, to name just a few.

Plasma sources require high voltages to operate and thus also need high-voltage transformers or RF generators in the gigahertz range. For manufacturability and safety reasons, the high-voltage power supply and the plasma generating unit in these sources are typically designed in separate housings.

Safety measures are necessary to protect users from exposure to the inherently high voltages, making existing solutions bulky. In addition, they can only use a limited selection of process gases. The market, however, is demanding high-performance solutions for cold, atmospheric pressure plasma generation that are compact, lightweight and easy to handle. The ideal product solution is battery-driven and supports a wide range of process gases.

Single component solution

A completely new kind of EPCOS component called CeraPlas meets these requirements. Developed in TDK’s Austrian competence centre for ceramic components, CeraPlas leverages, among other things, the know-how accumulated over many years in the volume manufacturing of piezo actuators and in multilayer ceramic technology. The development of CeraPlas is being conducted in close cooperation with relyon plasma, a leading manufacturer of plasma sources in Germany.

This new piezoelectric component enables the very efficient generation of cold atmospheric pressure plasma and uniquely combines the voltage transformation and plasma generation in a single component. As a piezoelectric transformer, it is able to generate the necessary high voltages while simultaneously generating plasma at the output side of the component.

Innovative piezoelectric material

The new patented technology is based on a hard PZT (lead zirconate titanate) ceramic material, which can be co-fired with internal copper electrodes. As a result, the material set offers both a high and stable mechanical quality factor over a wide range of strain, as well as good electromechanical coupling and low losses.

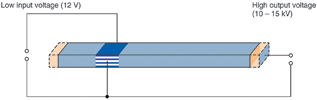

The component is designed as a multilayer, Rosen-type piezoelectric transformer: The input side features a multilayer structure with copper inner electrodes, while the output side of the transformer has a monolithic structure (Figure 1).

The voltage transformation is achieved at resonant frequency due to the formation of a standing acoustic wave which transforms the low voltage from the input side to a high voltage at the mechanically coupled output side. Because the piezoelectric transformer operates at the 2nd harmonic vibration mode, it can be contacted and mounted at the vibration nodal points without disturbing its mechanical movement.

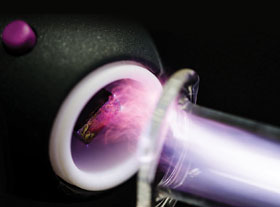

The standard dielectric barrier discharge (DBD) process used for plasma generation causes an electrical discharge between two electrodes that are separated by a dielectric barrier. With the CeraPlas, however, the discharge occurs directly on the surface of the piezoelectric transformer’s output side as a result of the generated high voltage. Since the piezoelectric transformer operates here as a dielectric electrode as well, there is no need for a discharge electrode such as required by conventional DBD solutions.

Charges collect on the surface of the dielectric material, where high electric fields are located and discharge within microseconds, leading to their reformation elsewhere on the surface. Similar to other electrical discharge methods, the plasma is sustained as long as the energy source provides sufficient ionisation.

Compact and safe

The EPCOS CeraPlas is a component that features compact size, low weight, low power consumption, a low input voltage and a high output voltage. It can be integrated easily into different plasma source concepts without the need for special high-voltage safety measures, thus giving it a high degree of application flexibility. All these beneficial properties are combined with outstanding performance regarding plasma temperature and surface activation.

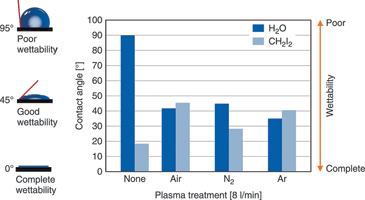

In comparison with conventional plasma generation techniques, CeraPlas achieves a more effective surface activation at very low power (Figure 2). Voltages up to 20 kV can be reached at the output of the component with a sinusoidal voltage of 12 to 24 Vpp, which is high enough to generate a discharge in air and other industrial gases such as nitrogen or argon (Figure 3). The plasma itself has a temperature of below 50°C and is therefore suitable for treating the surface of nearly all temperature sensitive materials.

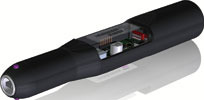

To enhance the efficiency of the CeraPlas component, a driver has been developed that is optimally matched to the requirements of the piezoelectric plasma generator. A piezoelectric transformer must be driven at its resonance frequency. For stable operation it is essential to immediately react to load and environmental changes. The prototype driving stage shown in Figure 4 with a CeraPlas plasma generator tunes the piezoelectric transformer and thus reduces potential stress to the component.

Plasma sources based on CeraPlas exhibit outstanding performance in comparison to existing low-power plasma generators. The overall plasma generator concept is very elegant, requiring only a low-voltage power supply, the driver, CeraPlas and an optional gas supply. Thus, depending on the application requirements, CeraPlas can enable a wide range of designs for plasma generation units: from simple pen designs and handheld devices up to integrated modules for industrial applications.

Commercial use of CeraPlas

The first product on the market based on CeraPlas is the piezobrush PZ2, a wear-free cold atmospheric pressure plasma source that was developed by relyon plasma in close cooperation with TDK (Figure 5). Needing no external processing gas, this compact handheld device produces plasma which is ignited by the CeraPlas component in the gas flow and features high activation efficiency.

Due to its low plasma temperature of less than 50°C, the piezobrush PZ2 can be used to activate temperature-sensitive materials. These features, combined with its compact size, show the potential for implementation in handheld devices and industrial plasma applications.

Samples of CeraPlas are now available, with series production currently in preparation based on the existing volume manufacturing technology for EPCOS multilayer piezoelectric components such as the successful piezo actuators for automotive fuel injection systems.

As the world’s first combined transformer and plasma-generating component, CeraPlas is suitable for use in a wide range of innovative applications such as surface treatment of car interior textiles and plastics, the sterilisation of food processing machines and medical devices, or even the direct treatment of wounds.

| Tel: | +27 11 458 9000 |

| Email: | [email protected] |

| www: | www.electrocomp.co.za |

| Articles: | More information and articles about Electrocomp |

© Technews Publishing (Pty) Ltd | All Rights Reserved