There is definitely an increasing interest in conformal coating for electronics, based on recent workshop and seminars run by the SMART Group in the UK and other organisations worldwide. I recently rekindled my interest and knowledge on the subject for a workshop session at SMT Nuremberg. Things have moved on a long way since my time as an apprentice using brush and manual spray coating techniques within GEC. Producing operator instructions and inspection criteria for the number of brush hairs allowed in a coating seems like a lifetime ago.

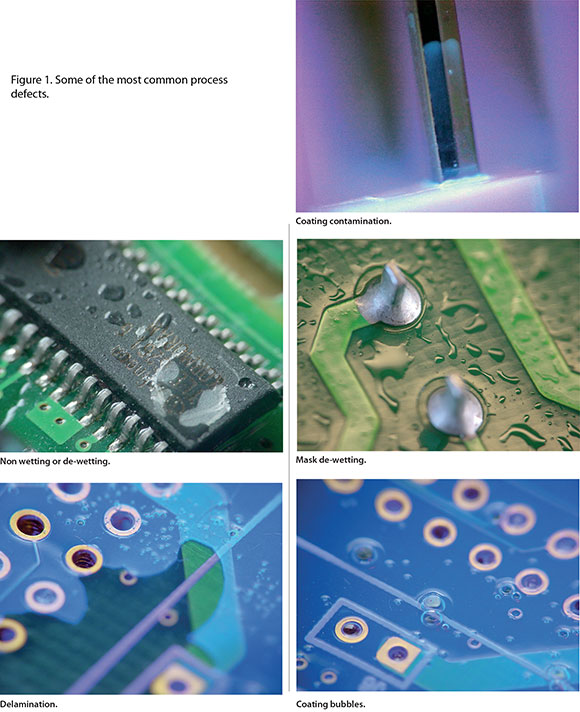

Simple process control checks can be invaluable during conformal coating. These may vary depending on the type of product, material, volume, application and design density. Some of the most common process defects are shown in Figure 1. Checking the wet coating thickness on the surface of the board after application, or alternatively on a blank panel, will make measurement simpler. Using a wet depth gauge, check the coating in two or three areas on a sample board, and ideally check more than one sample in a batch. Record the reading, location, material and process parameters for future reference.

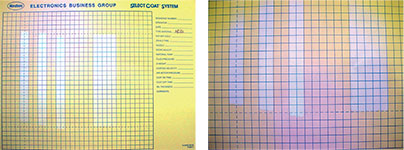

Coating a blank test board prior to running production or using a proprietary matrix test card like that used by Nordson ASYMTEK is a good way of checking spray process parameters (Figure 2). The test board or card can be inspected with a long-wave UV light for coating definition, overspray or coating run-on. Process parameters like solids content, temperature, nozzle type, speed, height and pressure can be recorded with the sample and retained for reference.

Measuring dry coating can be performed on a test label applied to the surface of a board prior to coating. The thickness of the dry label can be recorded prior to coating; subtracting the thickness of the label provides the coating thickness in that location. The label can be retained for future reference and is ideal for engineers to review during process audits. Digital thickness measuring systems are available for logging data for SPC.

With care, coated boards can be examined directly after spray coating using a UV light source on an outfeed conveyor. Care needs to be taken to avoid contamination and disturbance of the coating. Surface contamination with hairs, fibres or other particulate can be a problem with a delay before curing. Recent introduction of automatic optical inspection (AOI) specifically designed for coated boards can be used as off-line or in-line inspection with software which has been specifically developed for coating defects.

When coated boards are cured in a convection or IR oven the temperature profile must be established based on the material supplier’s recommendations. The profile must also be considered in relation to the coating thickness. Temperature profiling procedures should follow the techniques used for reflow soldering with the correct attachment of thermocouples. Attempts to speed up the curing cycle is a common cause of failures.

Inspect sample boards under UV lighting for complete coating coverage. Check areas of the board after removal of any masking for contamination or lifting of the coating at the masking interface. The coating should be compared with any work instructions, alternatively a golden coated board assembly should be available for reference. Obviously in high volume is where AOI systems will have an impact in the future.

During sample inspection of boards all defects and touch-up of the coating must be recorded for future review. Inspection should be based on documented inspection criteria or customer specification. Where new defects or PCB design specific issues are seen they should be photographed and added to inspection criteria, training updates or included with customer specific instructions.

Having images of common process defects and examples of satisfactory coating (see Figure 3) to include in PowerPoint training modules or for onsite work instructions is an ideal resource for process and quality engineers tasked with training sessions.

For more information visit www.bobwillis.co.uk

© Technews Publishing (Pty) Ltd | All Rights Reserved