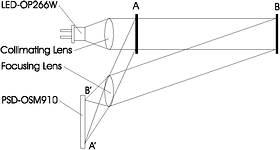

Triangulation sensors provide distance or range information without contacting the target object. A sensing system operates by projecting a beam of light onto the target and detecting where the reflected light falls along the length of the sensing photodiode. As the position of the target object moves closer or further from the light source, the reflected light spot on the detector changes (see Figure 1).

In this example the detector used is Optek's OSM910 position sensing detector (PSD). The following discussion will focus on the operating principles of the PSD and the basic elements of a triangulation system.

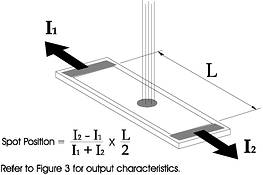

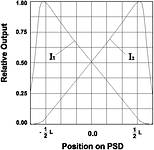

The PSD is a silicon photodiode that has an anode contact at each end of its length and a high resistance between the contacts. When a spot of light falls on the detector's surface, the current from each anode is proportional to the relative position of the spot. If the spot is centred, the currents will be equal. As the spot moves, the output currents change, allowing the position to be calculated by the formula shown in Figure 2.

The PSD is capable of operation up to 200 kHz and system performance is usually limited only by the signal processing electronics. Because the output is based on the centroid of the light spot, the light does not have to be focused tightly to obtain a valid distance reading. The outputs are independent of the light level between dark current and saturation because they respond proportionately to the lightspot. The PSD requires no initial calibration and no adjustments are required if the reflectance of the target changes. These characteristics make the PSD an excellent choice for use in distance measurement systems.

The triangulation system

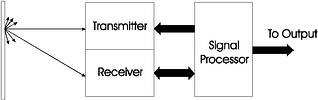

A triangulation system consists of three subsystems: the transmitter, receiver and signal processor. Figure 3 shows a system block diagram.

The transmitter

The light source chosen for Optek's triangulation example is aGaAIAs infrared LED, the Optek OP266W.

The package does not have a lens that allows the use of collimating optics to shape the beam. Other light sources suitable for the application include visible LEDs or laser diodes. In this case, the infrared LED was chosen because it is lower in cost than the laser diode and requires less drive current than a visible LED.

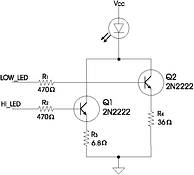

The drive circuitry for the transmitter includes a means for adjusting the drive current based on the output signals from the receiver. This is required to keep a consistent output level over the relatively wide distance range of 20cm to 100cm. In this application, two LED current levels are available: low and high. The LED drive is selected low if the PSD outputs are near saturation or selected high if the signal levels are near dark current. The LED drive circuit schematic is shown in Figure 5.

The receiver

The PSD outputs are fed into a buffer and amplification stage and then into separate analog-to-digital converters (see Figure 6). This method produces two digital signals that correspond to the magnitude of the currents produced by the PSD. The two analog signals could be combined before the digital conversion. It is left up to the designer to determine the best method for the application.

The signal processor

The processor for Optek's triangulation sensor is a one-time-programmable microcontroller with 2 Kbytes of internal ROM. When the processor receives the digital signals from the receiver, the data is analysed for signal strength and the LED drive is adjusted accordingly. The LED is then pulsed and readings are taken from the receiver. An average is obtained from 10 consecutive readings and the distance is calculated and displayed.

Conclusion

The optical triangulation sensor presented is capable of measuring the distance of a diffuse reflective object from 20 cm to 100 cm. By using the OSM910 PSD, system components and complexity are kept to a minimum without sacrificing accuracy or repeatability.

| Tel: | +27 12 657 3500 |

| Email: | [email protected] |

| www: | www.communica.co.za |

| Articles: | More information and articles about Communica |

© Technews Publishing (Pty) Ltd | All Rights Reserved