Careful consideration of the appropriate communication protocol and data rate, combined with the power-saving features offered by the latest RF devices, can all be used to reduce power consumption. The result is a wireless sensor node which can operate almost indefinitely and with little or no human intervention.

The simple energy harvesting techniques discussed throughout this article can be used to implement maintenance-free wireless sensors for cost-effective networking in applications such as smart homes, building automation and M2M communication.

Whilst the cost of a wireless network may start with the hardware, there are other factors which can add to the cost. These may include additional hardware and software costs, certification to standards such as ZigBee and Bluetooth, and also royalty costs.

Energy sources

The amount of energy that can be harvested by a wireless sensor is typically limited by cost and size. It is critical, therefore, to ensure that the amount of energy drawn by the sensor and the wireless transmitter is lower than the amount which can be supplied by energy harvesting.

There are a number of sources from which energy can be harvested, of which the most common is solar power. Solar panels come in sizes ranging from large panels integrating a high number of solar cells, to the small cells that are used to power products such as calculators and toys.

Other sources of power include radio waves, which are received by an antenna and converted into electrical energy, and the electromechanical energy which is harvested from a magnet moving near to an inductor coil. Temperature gradients can also be used to provide thermoelectrical energy for harvesting using the Seebeck effect.

A question of compatibility

Common wireless protocols such as ZigBee or Bluetooth may be the first that spring to mind when considering which wireless technology to use for an energy harvesting design, however not all designs will need to incur the cost or the complexity of using an industry-standard wireless protocol.

The choice will be based on the degree of compatibility required by each design. For example, a wireless headset for a mobile phone will almost certainly need to offer wide compatibility, whereas a simple RF remote control may not need or be able to support the cost of compatibility with other manufacturers’ products.

The cost of certification

Any design which includes a wireless sensor will need FCC or CE certification, so this cost is common across all designs. The cost of gaining certification to a specialised standard, however, will typically be higher than the cost for FCC or CE certification, and can often be under-estimated.

The overall cost of implementing a wireless standard goes much further than basic hardware and software costs. Before going through the compliance process the design will probably need to undergo pre-compliance testing.

Hiring the specialist equipment for these pre-compliance tests can cost around $750 per month. Then there is the cost of the actual certification process to a wireless standard, which will typically include costs for compliance testing, profile testing and the appropriate hardware sniffer tools. Altogether these tests bring the typical cost for certification to the ZigBee standard to around $3000. Then there may also be an annual membership fee as well as per-chip royalties which will need to be included.

The overall impact of certification on the cost per unit will depend on the production volume. Take, for example, a design with hardware costs of around $1 to $1,5 per unit over a production quantity of 10 000 units. At an estimated cost of around $10 000, certification to FCC would effectively double the cost per unit of the product. Then the cost of certification to an RF standard, including pre-compliance testing, the certification process and RF test equipment, could easily push the cost over $10 000.

Power optimisation

Effective management of power consumption is critical for a wireless sensor node powered by energy harvesting, and will have an impact on every design decision. The configuration of the RF transmission deserves special consideration to enable the system to eliminate all unnecessary power consumption.

Parameters such as the modulation scheme, the speed at which data is transmitted, and the RF output power into the antenna, will all affect the overall power consumption. As a general guideline, shorter periods of active operation will result in lower average power consumption. This can include ensuring that all of the devices used in the design, from an LED to a microcontroller or transmitter, spend the maximum time in low-power mode.

Power versus data rate

Using a higher data rate will mean that the design uses more power, but the trade-off is that shorter packet lengths will reduce energy consumption. The modulation scheme will also have a role to play in managing energy consumption. ASK or OOK modulation uses less energy because there are periods when the RF power is reduced with ASK modulation, or zero with OOK. The average current draw will also be lower with ASK. Despite this, the preferred modulation scheme is FSK because it can achieve significantly higher data rates.

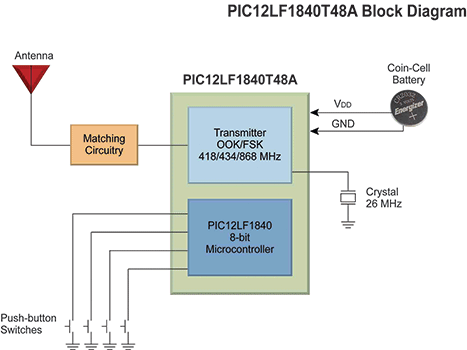

If basic one-way communication is all that is needed, the design could use a simple RF transmitter; but if the goal is certification to a wireless standard such as IEEE 802.15.4 then a specialised controller may be preferred. For example, Microchip’s PIC12LF1840T48A microcontroller has an integrated transmitter which supports a data rate of 10 Kbps in OOK mode and 100 Kbps in FSK mode. This data is therefore sent 10 times faster using FSK modulation than with OOK. At higher data rates, an RF receiver can also receive and decode FSK signals much more efficiently than with ASK modulation.

Managing energy consumption

The low-power shutdown modes of the microcontroller can also be used to minimise energy consumption. The frequency with which the sensor needs to transmit data will depend on the response time of each application. Extending the time between active periods will mean that the controller will spend more time in low-power mode and therefore reduce the average power consumption.

The current draw will also be determined by the type of data that the sensor captures between transmissions. Receiving data from op-amps and a bridge load cell, for example, will demand a relatively large current compared to the current used during the transmission of RF data.

Calculating energy consumption

An example design based on Microchip’s PIC12LF1840T48A microcontroller shows the calculations for energy consumption: The PIC12LF1840T48A’s integrated transmitter has a maximum frequency deviation of up to 200 kHz which allows a maximum bit-rate of 100 Kbps.

Using a small data packet with a 16-bit preamble, a 16-bit synchronisation pattern and a 32-bit payload, one complete data packet can be transmitted in just 640 μs. With the energy measured in joules (J) this provides:

1 J = 1 W * 1 s = 1 V * 1 A * 1 s

The energy consumption used for sending one data package is calculated by:

E = 10,5 mA * 640 µs → 10,5 mA * 3,0 V * 640 μs = 31,5 mW * 640 μs = 20,16 μJ

The startup time for the crystal oscillator is typically 650 μs, with an energy draw of 5 mA during startup. The startup power consumption is therefore calculated by:

E1 = 5 mA * 3,0 V * 650 μs = 9,75 μJ

The data transmission used in the example design contains 16 bits of preamble, 16 bits of synchronisation pattern and 32 bits of data. For the selected bit-rate of 100 Kbps, this gives a transmission time of 640 μs. For an RF transmission of +0 dB at 868 MHz, using FSK modulation, the power consumption is 12 mA.

E2 = 12 mA * 3 V * 640 μs = 23,04 μJ

Using a simple transmission at 10 Kbps the energy used would be:

E2 = 7,5 mA * 3 V * 6,40 ms = 144 μJ

This comparison shows the difference in the energy used and reinforces the importance of using a higher data rate.

The PIC12LF1840T48A transmitter will automatically time-out and revert to a low-power shutdown mode after sending the last data bit. With a minimum timeout period of 2 ms the additional energy consumption will be:

E3 = 12 mA * 3 V * 2 ms = 72 μJ

These calculations provide a total power draw for the transmission of a single data packet of:

E = E1 + E2 + E3 = 9,75 μJ + 23,04 μJ + 72 μJ = 104,79 μJ

A miniature solar cell that generates a current output of 4,5 μA at 3 V will need to be active for the number of seconds that are required to get enough energy for a single data transmission. Using a low-cost solar cell as an example, a best-case scenario of 3 V at 40 μA, only generates 120 μW of power:

3 V * 40 μA = 120 μW

The calculation for the amount of time required to collect sufficient energy to send a single data transmission is:

T = 104,79 μJ / 120 μW = 0,87 s

This shows that the sensor unit has to wait for 0,87 seconds between two sequential data transmissions, assuming that the solar cell has a constant light source. In real-world applications the natural light, which is the primary source of energy, is available only during the day. The calculation, therefore, must be extended to take into consideration the fact that the harvesting system must store the energy harvested during the day so that it can be used during the night. Another factor to consider is that the energy required to carry out the actual sensor measurement in not included in the example calculations.

Storing energy

There are a number of options which can be implemented to store the energy harvested during daylight hours. These options include using a supercapacitor as the storage element, or trickle-charging low-cost NiMH rechargeable batteries directly from the solar cell. In the few applications where the source of energy is constant, there may be no need for storage.

The case for energy harvesting

The main advantage of using energy harvesting in low-power wireless sensor nodes is not for an immediate reduction in the cost per unit, but for the long-term savings in maintenance costs. These savings are particularly useful if the sensor nodes are in remote locations, or if the network contains a high number of nodes. In both of these scenarios, energy harvesting could power the wireless sensors almost indefinitely and with virtually no human intervention.

Energy harvesting is becoming an increasingly viable solution for powering wireless sensor nodes, particularly in networks which are not based on networking standards such as ZigBee or Wi-Fi. There is also a growing range of energy sources such as light, heat, radio waves, mechanical energy and, more recently, even blood sugar.

The successful implementation of energy harvesting to power a wireless sensor node needs careful control of the wireless sensor’s overall power draw. This can be achieved by selecting the most appropriate communication protocol and data rate, and by using all of the power-saving features integrated into RF devices such as Microchip’s PIC12LF1840T48A microcontroller.

| Email: | willem.hijbeek@tempetech.co.za |

| www: | |

| Articles: | More information and articles about Tempe Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved