The growth of the mobile communications market is clearly in the newer digital wireless products. The consumer advantages are significant – improved transmission quality, accessibility, security and operating time.

Digital mobile communications devices transmit in short bursts which conserves power between transmissions, thus extending talk time of the battery. Likewise, during standby, some digital devices also ‘wake up’ and listen for incoming calls in short bursts, again extending battery life.

The resulting battery drain is pulsed current, ranging from milliamperes to amperes. Accurate current drain measurements are important to assure proper battery life for these different operating modes.

Mobile communications devices incorporate a wide variety of battery charging schemes. Constant and pulsed charge currents ranging from milliamperes to amperes are characteristic of rapid, slow and trickle battery charge modes of these devices. There are a variety of charge termination methods, all primarily determined by battery voltage.

In the production testing of mobile communications products, a system power supply replaces the battery. High-volume manufacturing often dictates that the device under test (DUT) fixture is located remotely from the test system, introducing significant impedance due to long wiring length.

This, in combination with pulsed current drain, makes it challenging to maintain a stable, transient-free voltage at the fixture just as if the DUT were operating directly from a battery. In addition to emulating the battery, the power supply can also provide current and voltage measurements required for testing and calibrating the DUT.

All of these things dictate the need for a system power supply with power sourcing, loading and measurement capabilities specially tailored for this application. By properly evaluating these unique needs of the test system and power supply, the test system designer can avoid production test problems by selecting a power supply suited for the application.

There are several unique needs to consider in the system current supply selection, specific to mobile communications device testing. These needs can be categorised as sourcing power, battery charger loading and current measurement.

Considerations when sourcing power to the DUT

There are important factors the designer needs to consider in sourcing power to the DUT:

1. Transient voltage drop at the DUT fixture.

2. Pulsed current sourcing for DUT transmit burst current drain.

A stable DC voltage at the test fixture is necessary in mobile communication device test. Transient voltage drop can be a particular problem due to the DUT transmit burst current drain and the impedance of long wiring connecting the test system to a remote test fixture. If the transient voltage drop is large enough, it will activate the DUT low-voltage shutdown circuit and disrupt the test, impairing test throughput and yield.

Since digital mobile communications products draw current in pulses, the average current is low compared to the pulsed current. Being able to specify the power supply based on pulsed instead of average current capability can result in a smaller and less costly unit. Careful evaluation of these current sourcing capabilities will assure optimum performance at the remote DUT test fixture.

1. Transient voltage drop at the DUT fixture

The transient voltage drop should be kept below 150 mV for mobile communications devices operating at 3,6 V. The transient voltage response specification on typical power supplies is not adequate to assure proper performance in this application. It specifies the performance directly at the power supply output terminals operating in local voltage sense mode. It does not consider the wiring voltage drop that the power supply is attempting to compensate for when operating in remote voltage sense mode.

Moreover, most power supplies do not have sufficient speed to match the fast rise and fall times of the DUT transmit burst current. As a result, the actual transient voltage drop may be significant at the DUT even when the power supply is operating in remote voltage sense mode.

A suitably fast-responding power supply can provide an order of magnitude reduction of the transient voltage drop. However, at this fast response speed, the test set wiring, relays, connector resistance, wiring inductance, and the DUT’s characteristics, all influence transient voltage drop performance. A fast-responding power supply typically provides optimum performance only over a specific range of operating conditions.

Test system parasitic elements

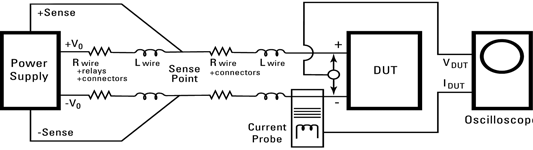

The parasitic elements in the test system are wiring, relay and connector resistance, and wiring inductance, modelled in Figure 1. To evaluate transient voltage drop, one must test over the range of expected parasitic values. The variety of test platforms in production, R&D, service and repair benches should also be considered in determining the range of parasitic values to be expected.

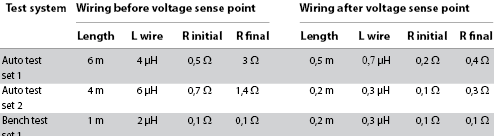

Typical parasitic values for the test system wiring are as follows:

* Wiring inductance; 1,5 to 2 μH/metre untwisted, 0,5 to 1 μH/metre twisted.

* Wiring resistance; depends on diameter; add 50% for twisted.

* Connector or relay resistance; initial: 0,01 to 0,05 Ω.

* Connector or relay resistance; end of life: 0,1 to 0,5 Ω.

These values are for illustrative purposes. It is important to estimate the parasitic values over the anticipated test system life. Otherwise an increasing frequency of unexplainable intermittent problems could occur as the test system connectors and relays wear.

One should always try to minimise these test system parasitic values as much as is practical.

Simulating the test system parasitic elements

The best final proof of performance is with the actual test system. When using the test system, it is important to ascertain the condition of the relays and connectors. To properly test at initial conditions, any worn components should be replaced.

In many cases the actual test system may not exist yet. The test system wiring parasitic values can be simulated using appropriate lengths and diameters of actual wire pairs as called for in the design. Untwisted wire pairs should be kept closely spaced to minimise loop area and resulting inductance and noise pick-up. Connector and relay initial and end-of-life resistance can be simulated using appropriate non-inductive resistors.

It may be useful to set up a matrix for the range of parameters and conditions to conduct the evaluation, similar to Table 1.

The DUT characteristics

The range of various different models of DUTs likely to be tested need to be taken into consideration in the transient voltage drop evaluation testing. Typical ranges of DUT talk-mode operating values may be as follows:

* Operating voltage: 2,5 to 8,0 V.

* Talk-mode low-level pulsed current drain: 75 to 300 mA.

* Talk-mode high-level pulsed current drain: 0,8 to 2 A.

* Talk-mode initial peak transient current drain: 1,2 to 3 A.

* Pulsed current drain rise and fall times: TDMA: 25 microseconds or slower; GSM: 17 microseconds or slower; CDMA: 3 microseconds or slower.

A mobile communications device’s battery input port is very complex with regard to its impedance and actual pulse wave shape. It is important to conduct testing with actual DUTs to verify true transient voltage drop performance.

DUT operating conditions to consider

The DUT should be set to maximum transmit power and be operated at the lowest input voltage to get maximum current drain. This will usually give the largest transient voltage drop.

System performance should also be verified at maximum DUT operating voltage to verify that the power supply still has adequate voltage reserve to compensate for peak voltage drop in the wiring. One should check transient voltage drop performance with all DUTs to be tested on the system.

It is worthwhile documenting the actual DUT characteristics used to conduct the evaluation for future reference.

Using an electronic load to simulate the DUT

One should not depend on using a commercial electronic load or power transistor and pulse generator to simulate the DUT pulsed drain current to verify transient voltage drop performance. Their characteristics are very different in comparison to an actual DUT. The results will be approximate at best, so the final proof is to always use an actual DUT.

Transient voltage drop evaluation example

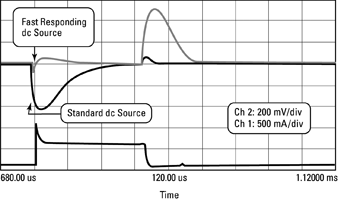

The transient voltage drop performance and pulsed current drain are measured directly at the DUT with an oscilloscope and current probe, as shown in Figure 1. Typical values of these measurements are illustrated in Figure 2.

It may be useful to set up a matrix for the range of parameters and conditions to track the results of the evaluation, as illustrated in Table 2. Again, it is important to test the DUT at both low and high operating voltage limits.

2. Pulsed current sourcing for DUT transmit burst current drain

Power supplies specifically developed for this application may offer pulsed current sourcing capability that exceed their DC average current sourcing capability. This effectively provides more power in a smaller package for digital mobile communications devices, which draw current in pulses.

The pulsed current drain of digital mobile communications devices

Two common examples for transmit bursts are TDMA and GSM products.

* TDMA transmits in 6,67 millisecond bursts with a 2/6-duty cycle.

* GSM transmits in 0,57 millisecond bursts on a 1/8-duty cycle.

In application, the DUT operates at a specified voltage and draws current based on its power needs. The voltage is being controlled by the power supply while the levels of current are being determined by the DUT.

Simulating the DUT pulsed current drain

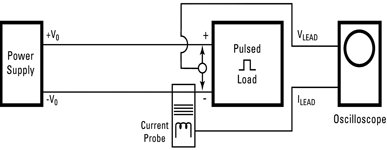

The evaluation needs to reflect the application conditions, to correctly test the suitability of a power supply’s pulsed current sourcing capability. In Figure 3, the power supply is set to the DUT operating voltage. An electronic load is set to alternate between two constant current levels to simulate the pulsed current drain of a DUT.

Both the DC average current and pulsed current levels need to be considered.

A power supply that provides pulsed current sourcing capability has a fast current limit to protect from excess peak current drain and a slow current limit to protect from excess DC average current drain. These limits protect the power supply as well as the DUT.

Measuring the power supply’s pulsed current sourcing capability

To measure the pulsed current sourcing capability, the electronic load pulse duration is increased while duty cycle is decreased to avoid exceeding the DC average current sourcing capability of the power supply.

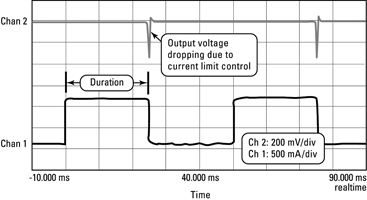

When the pulsed current sourcing capability is exceeded, the pulsed current limit takes over control of the source output collapsing the output voltage. The pulse current source duration is the time taken from the start of the current pulse to the collapse of the output voltage as observed by the oscilloscope trace example in Figure 4.

This testing can be conducted at several pulse current levels to determine the duration for each as the duration may be a function of the pulse level.

Applying a short circuit to measure the pulsed current sourcing capability

Applying a short circuit to the power supply output may not correctly measure the pulsed current source duration as required in the application. A short circuit instantly drives the power supply into current limit operation. This does not reflect the constant voltage operation and DUT’s repetitive current pulse drain of the application.

Minimising the transient voltage drop at the DUT fixture is a primary concern as it impacts production throughput and yield. A fast responding power supply can significantly reduce transient voltage drop. Output pulsed current source capability is beneficial by reducing the size and cost of the power supply in the test system.

The Agilent 66111A, 66311B/D and 66309B/D DC sources feature fast response and pulsed current source capability.

The second part of this article will run in a future issue of Dataweek, and will look at considerations when loading the DUT battery charger and when making power measurements.

| Tel: | +27 12 678 9200 |

| Email: | [email protected] |

| www: | www.concilium.co.za/test-measurement |

| Articles: | More information and articles about Concilium Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved