Printing using micro stencils for LGA/QFN rework

EMP 2018 Electronics Manufacturing & Production Handbook

Manufacturing / Production Technology, Hardware & Services

By Bob Willis.

If you are repairing land grid array (LGA) or area array devices, should you print the circuit board or the device terminations?

Either method can work, with your own skills determining which is easier and more repeatable.

Recent hands-on rework workshops proved very successful for the author and delegates reworking these fairly new packages. Special thanks go to TECAN in the UK for making the handheld manual rework foils specifically designed for QFN (quad flat no-lead) and LGA packages. Let us now step through the process in this step-by step-guide.

Figure 1. Hand print stencil for land grid array package with a 0,004” foil.

Firstly, make sure that the solder paste being used in rework is the same as in production. Often a dispense grade with larger ball size or lower metal content is used in repair areas but may not be suitable for stencil printing these fine pitch parts.

Select a micro stencil for the component footprint for a land grid array; this would normally be 0,004” (100 μm) foil (Figure 1). The stencil apertures for the outer pads are produced as one to one apertures. The centre aperture can be single or multiple apertures to cover between 50% and 60% of the surface area. It is recommended to have the paste printed to the centre of the device, not to the edge of the centre pad.

The stencil, being very thin, has a backing foil of between 0,010” and 0,012” thick and allows the stencil to be used for manual hand printing.

Figure 2. Laminated support foil welded to stencil foil providing a location for the package alignment.

The thicker support foil (Figure 2), prevents the image foil being flexed during printing, which can lead to inconsistent deposits. The support foil also allows the component to be positioned accurately to the terminations (Figure 3).

Figure 3. LGA is located in the support foil cavity for printing.

Place the LGA/QFN component into the stencil guide and check the right stencil is being used and the apertures are perfectly aligned with the terminations. One finger can be used to hold the component in position while the stencil is turned over for printing (Figure 4). Alternatively a small piece of Kapton tape can be used to hold the part in position.

The component can now be printed with solder paste using a small metal rework squeegee blade. It is important to use the blade in the same way as a printer; make sure the paste is rolling and the surface of the stencil is clean after the print stroke. Inspect to confirm that the paste is completely filling the apertures.

Figure 4. Stencil is turned over while still holding the LGA in place and manually printing with solder paste.

Before printing solder paste onto components, try printing paste images onto a flat surface like copper clad laminate, glass or thick white card. This will allow an opportunity to perfect the repair printing process. When the correct technique has been mastered, check the cleanliness of the stencil apertures and base to prevent contaminating the component surface with paste.

Figure 5. The LGA is lifted from the cavity and placed on the printed board for reflow. Alternatively the stencil is located on a rework system so the machine can lift the printed component directly and place the part on the surface of the board.

Turn the stencil over so the part can be lifted prior to placement (Figure 5). If the component is lifted manually it can be inspected visually prior to placement on the board. If the stencil is going to be located on a rework system the component can be placed automatically, and inspection of the paste deposits can be conducted on the rework system when the component is aligned with the pads prior to placement.

Make sure you check the stencil after use and clean or check for paste remaining in apertures if you intend to print a second device. Paste release from the stencil is just as important as printing in normal manufacture to achieve the best yields.

Another option is to jet print the solder paste directly to the board or on the surface of the component, just like manual printing. There are two or three jetting systems on the market today, one of which is a benchtop system which is perfect to use for rework or bumping packages.

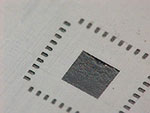

Figure 6. Close up of dummy LGA package used in training and printed with paste.

Bumping QFN/LGA packages can improve reliability and decrease voiding during reflow.

For more information visit www.bobwillis.co.uk

Further reading:

Transparent rigid PCBs launched on PCBWay

PCBWay

Manufacturing / Production Technology, Hardware & Services

[Sponsored] PCBWay is thrilled to announce a highly anticipated new service - transparent rigid PCBs – a combination of technology and aesthetics.

Read more...

20 years of precision, progress and purpose – the Jemstech journey

Jemstech

Editor's Choice Manufacturing / Production Technology, Hardware & Services

Twenty years ago, Jemstech began as a small, determined venture built on technical excellence and trust. Today, it stands among South Africa’s leading electronic manufacturing service providers.

Read more...

An argument to redefine IPC class definitions for class 1, 2, & 3 electronics

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

One of the most critical aspects of electronic assembly reliability is cleanliness. Contaminants left on a circuit board after the reflow process can lead to failures through mechanisms such as electrochemical migration or corrosion.

Read more...

Large platform stencil printer

Techmet

Manufacturing / Production Technology, Hardware & Services

GKG’s large platform stencil printer, the P-Primo, is designed to meet customer’s ultra-large printing requirements by supporting board dimensions up to 850 x 610 mm.

Read more...

Press-fit component inspection

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

In electronics manufacturing, optical inspection of press-fit components is crucial to ensure the quality, reliability, and performance of the final assembled product.

Read more...

A new era in wire bond inspection

Techmet

Editor's Choice Manufacturing / Production Technology, Hardware & Services

Viscom is developing a 3D wire bond inspection system that incorporates substantially improved sensors, a high image resolution, and fast image data processing.

Read more...

High-speed, high-resolution material deposition system

Manufacturing / Production Technology, Hardware & Services

ioTech recently unveiled the io600 inline digital laser material deposition system at productronica 2025.

Read more...

Mycronic’s MYPro A40 pick-and-place solution

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

Mycronic’s MYPro A40 pick-and-place solution, equipped with an MX7 high-speed mounthead technology, increases top placement speeds by 48% over the previous generation.

Read more...

Why ergonomics matters in digital microscopy

TANDM

Manufacturing / Production Technology, Hardware & Services

While magnification technology has kept pace with demand, the wellbeing of the people behind the microscopes has often been overlooked with technicians spending long hours in intense focus, leading to chronic strain, fatigue, and costly mistakes.

Read more...

From ER to effortless: The 15-year journey of Seven Labs Technology

Seven Labs Technology

Editor's Choice Manufacturing / Production Technology, Hardware & Services

What started as a business likened to an ‘ER’ for electronic components has today grown into a trusted partner delivering kitting services and full turnkey solutions – taking the effort out of electronics and helping customers truly ‘Move to Effortless.’

Read more...