Product development issues explored in new video

27 March 2019

Manufacturing / Production Technology, Hardware & Services

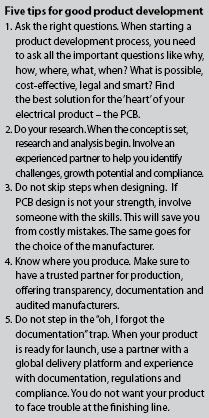

Printed circuit broker, Elmatica, recently released a new film about product development, explaining why cooperating with an experienced partner could be a smart move.

“We have several times seen the unfortunate result of inadequate planning and execution in the early phase of the product development process, explains the company’s CEO, Didrik Bech. “Early involvement of an experienced partner in the design phase can save you from costly mistakes. This new movie is meant to inspire all parties involved in product development, and bring attention to doing things correctly, from the beginning. At Elmatica we value transparency and sharing knowledge, we are not reluctant to share our know-how or ask the challenging questions.”

The animated movie (accessible at www.youtube.com/watch?v=kGFJvLBqmCE) follows a product, this time a robot, from when the idea is hatched in the designer’s head until the finished product is loaded safe and sound on an aeroplane towards the end customer. The whole process is supported by the printed circuit broker.

“The product development process is broken down as a six-step process from idea generation to launch. We want to focus on how close cooperation with an experienced partner, which knows PCBs by heart, can improve the process and ensure that cost and time saving elements are considered in all phases,” says Bech.

Changes in the supply chain

Elmatica has supported the development of thousands of products since its establishment in 1971. Even if the process is more or less the same in 2019 compared to 1971, some things have changed as several companies have outsourced parts of their supply chain and products have increased in complexity, with the result that many are often more reliant on external knowledge and specialists.

“We have organised our products to match different parts of your development process. This makes it easier for you to understand what we do, and for you to decide when and how you would like to include us. In this movie, we show how each of our products can fit with your product development process, supporting it from the beginning until the end, delivering technical assistance, auditing, experience, seminars and contacts,” says Bech.

For more information visit https://elmatica.com/contact/

Further reading:

Transparent rigid PCBs launched on PCBWay

PCBWay

Manufacturing / Production Technology, Hardware & Services

[Sponsored] PCBWay is thrilled to announce a highly anticipated new service - transparent rigid PCBs – a combination of technology and aesthetics.

Read more...

20 years of precision, progress and purpose – the Jemstech journey

Jemstech

Editor's Choice Manufacturing / Production Technology, Hardware & Services

Twenty years ago, Jemstech began as a small, determined venture built on technical excellence and trust. Today, it stands among South Africa’s leading electronic manufacturing service providers.

Read more...

An argument to redefine IPC class definitions for class 1, 2, & 3 electronics

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

One of the most critical aspects of electronic assembly reliability is cleanliness. Contaminants left on a circuit board after the reflow process can lead to failures through mechanisms such as electrochemical migration or corrosion.

Read more...

Large platform stencil printer

Techmet

Manufacturing / Production Technology, Hardware & Services

GKG’s large platform stencil printer, the P-Primo, is designed to meet customer’s ultra-large printing requirements by supporting board dimensions up to 850 x 610 mm.

Read more...

Press-fit component inspection

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

In electronics manufacturing, optical inspection of press-fit components is crucial to ensure the quality, reliability, and performance of the final assembled product.

Read more...

A new era in wire bond inspection

Techmet

Editor's Choice Manufacturing / Production Technology, Hardware & Services

Viscom is developing a 3D wire bond inspection system that incorporates substantially improved sensors, a high image resolution, and fast image data processing.

Read more...

High-speed, high-resolution material deposition system

Manufacturing / Production Technology, Hardware & Services

ioTech recently unveiled the io600 inline digital laser material deposition system at productronica 2025.

Read more...

Mycronic’s MYPro A40 pick-and-place solution

MyKay Tronics

Manufacturing / Production Technology, Hardware & Services

Mycronic’s MYPro A40 pick-and-place solution, equipped with an MX7 high-speed mounthead technology, increases top placement speeds by 48% over the previous generation.

Read more...

Why ergonomics matters in digital microscopy

TANDM

Manufacturing / Production Technology, Hardware & Services

While magnification technology has kept pace with demand, the wellbeing of the people behind the microscopes has often been overlooked with technicians spending long hours in intense focus, leading to chronic strain, fatigue, and costly mistakes.

Read more...

From ER to effortless: The 15-year journey of Seven Labs Technology

Seven Labs Technology

Editor's Choice Manufacturing / Production Technology, Hardware & Services

What started as a business likened to an ‘ER’ for electronic components has today grown into a trusted partner delivering kitting services and full turnkey solutions – taking the effort out of electronics and helping customers truly ‘Move to Effortless.’

Read more...