Digital manufacturing is seen as one of the next major leaps within the manufacturing value chains. This digital revolution promises to align product and production processes from concept to the end consumer. Potential is huge and could hold opportunities in the reduction of costs, time to market and improvement of production processes.

According to Siemens (2017) the digital manufacturing environment may be defined as “the use of an integrated, computer-based system comprised of simulation, three-dimensional (3D) visualisation, analytics and various collaboration tools to create product and manufacturing process definitions simultaneously”. It is indeed a complex topic and is being studied and published widely worldwide. Various countries launched initiatives and are contributing to the body of knowledge, from Industry 4.0 originating in Germany, the Made in China 2025 initiative from China, and even South Africa’s own government and private sectors seeking solutions to implement it locally. There are, however, many burning questions that the business environment within South Africa would have to answer when it comes to taking the leap into the digital manufacturing world.

Do we have sufficient infrastructure on which to implement the digitisation process or are we still stuck in manual manufacturing processes that haven’t been automated properly? Is this the playground of large multinational companies or can the technologies and processes be applied to smaller businesses? How do we develop the future workforce to be prepared for the changes that the digital manufacturing environment will bring? Which enablers, technological or not, are required to implement digital manufacturing in the business?

To supply some of the answers to these questions, Accenture Strategy (2016) identified 11 enablers that companies must consider if they wish to implement digital manufacturing within their environment. These are: digital foundation, intelligent automation and control, operational analytics and process monitoring, digital safety and energy management, mobility, advanced technologies, engineering collaboration, digital production system, talent development and learning, manufacturing control tower, and industrial security.

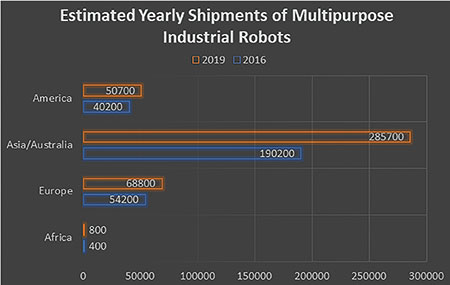

What really drew my attention was the potential that digital manufacturing holds for the development of staff in new ‘high-tech’ skill sets. The workforce will have to be upskilled in how to deal with smart technologies (Deloitte, 2016). This would include skills in information technology, digital technologies, as well as IoT technologies. Africa also faces major challenges in manufacturing infrastructure and connectedness as an enabler for digitisation. Challenges are further made clear by the diagram below from the International Federation of Robotics showing the number of industrial robots being imported to various countries. The fact is that Africa is lagging behind the rest of the industrialised countries.

Examples of successful digital manufacturing implementation are far and few between, with many still in a trial phase showing the potential a fully automated system holds. Industry 4.0 also heightens fears that the digitisation of manufacturing will reduce the workforce required in factories to the point where they are completely run by machines. If this statement is taken seriously without further research it could offer significant barriers to the implementation of these platforms in countries where manufacturing employs a large number of the workforce. In my view it would be more correct to state that (in the immediate future) Industry 4.0 offers improvements in the existing processes, but human beings would still run processes required to implement and evolve the system.

The technology for implementation in various industries would also have to grow exponentially and be able to offer the same adaptability that humans offer within the manufacturing industry to be a significant threat to a workforce. While the technology evolves, the opportunities will be there for companies to develop their workforce and implement the technology in phases until they see the full benefits promised by digital manufacturing technologies and strategies. In the long run companies adopting this approach would be able to receive better information that could be used to develop improved predictive methods for maintenance, production, product planning and also staff development in the adoption, use and adaptation of technologies.

In conclusion, Jeff Immelt probably explained it best by saying that if companies like it or not, more and more of them would have to change their technologies, people and business models to operate in the information space. Countries in Africa are thus at a cross roads; be the first to trial the technologies and strategies being offered by digital manufacturing, or wait and see what happens to their competitors and risk seeing them improve to the point where they dominate existing and new manufacturing processes.

For more information contact Kobus Vorster, Technology Station in Electronics, +27 (0)12 382 5039, [email protected], www.facebook.com/technologystationinelectronics

| Tel: | +27 12 382 5039 |

| Email: | [email protected] , [email protected] |

| www: | www.tselectronics.co.za |

| Articles: | More information and articles about Technology Station in Electronics |

© Technews Publishing (Pty) Ltd | All Rights Reserved