While large-scale conflict can often result in technological breakthroughs, the pursuit of peace may drive innovation too. This dichotomy has far reaching implications that help shape the modern world.

There are many parallels between the commercial and high-reliability electronics sectors, with a history of cross-fertilisation. The concept of commercial-off-the-shelf (COTS) has existed within the defence sector for several decades, while the design philosophy of open architectures arguably started in Hi-Rel sectors but now pervades the IT industry. Standards exist because large industries like aerospace/defence support a huge number of suppliers that must be able to cooperate yet remain competitive.

The aerospace/defence industry benefits from and helps drive innovation in the global electronics industry. The size of the defence market encourages investment and this can often shape the direction of other markets, while conversely trends like IoT also exert an influence on the way the defence industry develops. This symbiosis means many of the technologies primarily developed for one market will have applications in others, helping to mitigate risk and therefore promote greater overall confidence in R&D spend by semiconductor manufacturers.

Like any other industry, the aerospace/defence sector needs to balance effectiveness with efficiency, and modern developments are apparent here too. In some respects, this sector is at the forefront of technological advancements, such as using augmented reality (AR) and virtual reality (VR) to help supplement having the right expertise in the right place at the right time.

Using AR, it is now possible to have the hands of a soldier in the field being ‘guided’ by a more experienced soldier (who may be located anywhere in the connected world). This not only provides greater expertise in critical situations, but reduces the dependency on a small number of experienced soldiers. The same is true in medicine – where a doctor with expertise in a particular procedure can assist another medical professional, without being present in the same theatre.

Just as with the commercial sector, some of the focus in aerospace/defence is now on the potential of wearable technology, and how it could be used to monitor the health of deployed infantry. New wearable solutions (or more specifically hearable solutions, as they are worn in-ear) provide continuous access to vital statistics such as core body temperature and heart rate, as well as a way of tracking and locating the particular soldier.

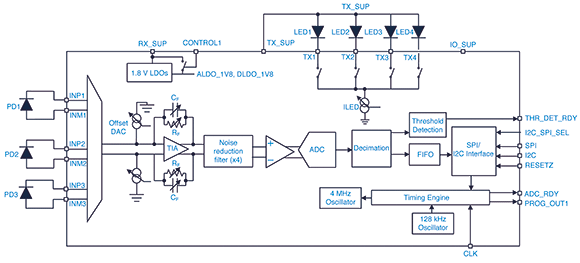

This is being enabled by developments like the AFE4410 from Texas Instruments – an ultra-small analog front end (AFE) designed for wearable devices. The device is intended to provide functions including continuous heart rate monitoring and oxygen consumption through optical biosensing. This involves using LEDs and photodiodes, with the AFE4410 simultaneously driving up to three LEDs optimised for biosensing.

The block diagram shown in Figure 1 highlights the main functions: a transimpedance amplifier, ADC, 128-sample FIFO, programmable LED driver and I²C/SPI interface. The highly integrated AFE solution is housed in a 0,4 mm pitch DSBGA package measuring just 2,6 x 2,1 mm.

Satellite positioning is a well known and often cited example of how technology developed for military applications now has a bearing on modern life. Receivers are used in conjunction with mapping software to put advanced navigation at the fingertips of most car or smartphone owners. With several satellite systems now in place, providing redundancy and greater coverage, receiver technology has advanced enough to enable a wider range of applications – such as asset tracking, personal navigation and geotagging.

The MAX2769C from Maxim Integrated is a single-chip universal global navigation satellite system (GNSS) receiver that works across the GPS, Galileo, BeiDou and GLONASS positioning platforms. It integrates a complete receiver chain and measures just 5 x 5 mm (making it small enough to be used in practically anything), while its high level of integration reduces the overall bill-of-materials (BOM). The device can be evaluated using the MAX2769CEVKIT, which is supported by control software and requires no additional circuitry.

Another trend that has had a significant impact in both aerospace/defence and consumer sectors is unmanned aerial vehicles (UAVs), also referred to as drones. The latest developments here see the addition of greater autonomy, which will allow these units to not only self-stabilise but actually determine their own flightpaths. Such drones can be used for reconnaissance and maintenance inspections in dangerous or hazardous environments, or simply to reduce the human effort required.

The Outrider is a prime example. Developed by Lockheed Martin and officially announced at the recent Defence and Security Equipment International Exhibition, this diminutive UAV measures just 10 cm wide and weighs around 1,7 kg. Capable of being launched from a canister, it has been developed for use under conditions where a more conventional, larger-scale UAV deployment wouldn’t be feasible.

The functionality that underpins self-flying drones includes positional awareness. This goes beyond just GPS coordinates, it includes inclination, attitude, rotation, velocity and altitude. Measuring these parameters is enabled through the development of highly accurate sensors, which are increasingly realised through micro electro-mechanical system (MEMS) technology.

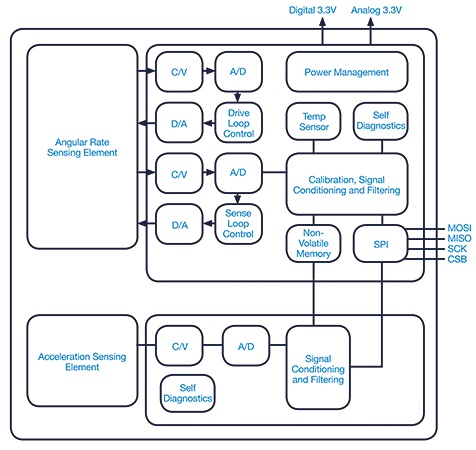

MEMS are characterised by their small size and low power, which makes them viable for wearable technology as well as autonomous drones. The integration of multiple MEMS sensors has given rise to a class of device known as inertial measurement units (IMUs). Many of these have been designed specifically for control and navigational systems, like the SCC2230-E02 from Murata, which combines a three-axis accelerometer with a z-axis angular rate sensor (Figure 2 shows a block diagram of the main functions).

The sensors are manufactured using Murata’s high aspect ratio 3D-MEMS technology. It works by detecting changes in capacitance, caused by moving masses, with changes sensed and processed by the integrated signal conditioning ASIC. All functions are accessed through the SPI interface.

One technology with a long history in aerospace/defence, which is now making its way into other markets, is radar. The automotive industry is moving towards radar for advanced driver assistance system (ADAS) implementation and it will no doubt be instrumental in the progression of self-driving cars. It also has the potential to shape the future of the UAS (unmanned aircraft system)/drone market.

Accessing the technology that enables radar is now easier than ever, thanks to the availability of evaluation platforms such as the EV-RADAR-MMIC2 from Analog Devices. This kit has been developed to give developers access to the ADF5901 24 GHz transmitter, ADF5904 24 GHz receiver and ADF4159 13 GHz PLL, which are all used in the development of frequency modulated continuous wave (FMWC) radar systems.

Recent years have seen an erosion of the invisible barrier separating technologies targeting specific vertical sectors. What was once intended for use in national defence may now be found in every home (think virus protection software or data encryption). While in a similar manner, the technology used to record a person’s sporting activity is now also being employed to monitor a soldier’s vital statistics in the field. As this cutting-edge technology becomes more accessible, we can expect to see new applications emerge that will further encourage cross-fertilisation and even greater innovation.

For more information contact TRX Electronics, authorised Mouser partner in South Africa, +27 (0)12 997 0509, [email protected], www.trxe.com

| Email: | [email protected] |

| www: | www.trxe.com |

| Articles: | More information and articles about TRX Electronics |

© Technews Publishing (Pty) Ltd | All Rights Reserved