Temperature sensors are used in a wide range of functions, ranging from shut-down in the event of an over-temperature condition, to display temperature and thermal calibration in high-accuracy systems.

System performance can be improved, and development cycles shortened, if the most suitable temperature sensor for a specific application is chosen from the outset.

The design pressures of different applications have resulted in a number of different approaches to silicon-based temperature sensing, differentiated by their output signalling method. The first silicon-based sensors were simple analog types. However, demands for system simplicity have brought about a number of ICs that integrate a significant part of the signal-conditioning circuit. The most popular varieties of these offer a voltage, logic or digital output.

Analog sensors

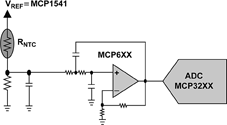

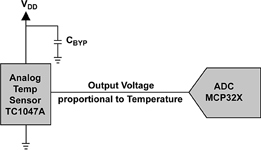

The basic analog sensor works in a way very similar to a thermistor, providing a voltage output that is proportional to the measured temperature. When a linear relationship between temperature and output voltage is needed, a silicon temperature sensor is a better choice than a thermistor, as it eliminates the need for an external linearisation circuit (see Figure 1). Analog temperature sensors are available with different output scales (K,°C or °F) and also with voltage offsets, which allow negative temperatures to be monitored while using a single-ended supply. The output signal of an analog temperature sensor can be fed to a comparator to generate an over-temperature indication, or it can be input to an A/D converter for displaying realtime temperature data (see Figure 2). Analog temperature sensors are ideal for applications requiring low cost, small size and low power consumption.

Digital sensors

The logic-output temperature sensor, also known as the temperature switch, outputs a logic-level signal when a measured temperature is higher (or lower) than a specified limit. The trip point (limit) is either factory-programmable or can be set via an external resistor. This type of sensor has the benefits of low cost and ease of design-in. Additional functions, such as adjustable hysteresis level and multiple trip points/output signals, are often available. Typical applications include systems that require an over- or under-temperature indication to shut down the system (temperature alert), and those that turn on a fan or start a heater (thermostat control).

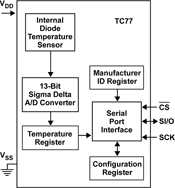

As the need for sophisticated control, better accuracy and higher resolution has grown, digital temperature sensors have been developed to meet that need. These sensors provide direct temperature readings without the need for other external components. They accomplish this by integrating all the necessary functions in space-saving packages (see Figure 3). A major advantage of the digital interface is the increased sophistication offered by the temperature-control loop and the software control, allowing an easy upgrade when changing system hardware or thermal properties. Applications for these sensors include CPU/board thermal protection and system thermal calibration.

Selecting to application

Faced with this choice, designers can simplify the selection process by carrying out a preliminary evaluation of the end application, its purpose and its requirements. The attributes to be considered include temperature range, total cost, thermal-response time, package size, interface electronics location, and required accuracy.

A typical application for modern digital thermal temperature sensors is the protection of electronic components and systems. Thermal protection of sensitive components becomes critical as system designers are asked to pack more functions, operating at higher speeds, into smaller packages. For example, the Intel Pentium processor dissipates up to 16 W at 66 MHz and will be damaged if the cooling system fails. High ambient temperatures can also degrade performance or damage components in communications systems, file servers, power supplies, motor drives and many other applications where heat is generated.

These components and systems are easily protected with semiconductor temperature sensors because the sensor operating characteristics and packaging are compatible with the components being protected. Proper mounting of the temperature sensor in relation to the heat source is critical to ensure correct results. Therefore, it is important to select the correct package for a particular task. Microchip's TC62X family for example, includes variants with internal sensors and others for use with external sensors, and is available in a wide variety of packages.

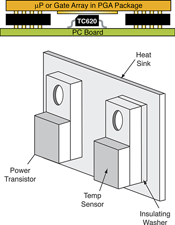

For example, protecting a microprocessor such as Intel's Pentium is simplified when a TC620 in an SO package is mounted underneath the microprocessor's pin grid array (PGA) package (see Figure 4). The two set-points provided by the device allow designers to offer a 'graceful' shut-down procedure: if the low set-point temperature is exceeded, unnecessary peripherals can be shut down, files backed up, and a system warning generated; if the high set-point is exceeded, the system is shut down to prevent damage to the CPU.

Protecting power transistors, diodes and similar components is easy when the TO-220 variant of the TC622 is used (Figure 4). The tab of the TC622 package is internally connected to VCC, so an insulating washer may be required if the heat sink is at a potential beyond the TC622's VCC range of 4,5 V to 18 V.

Measuring the internal air temperature inside a system is accomplished using the DIP, small outline (SO) or TO-220 packages. Since the sensor is mounted in the same type of package as other ICs, and is at the PC board level, its output will accurately reflect the actual environment of components within the system. For measuring specific hot spots on sensitive components, the TC621 offers a wide variety of options when combined with an almost infinite selection of thermistor packaging types.

Sensing that a component is too hot is not sufficient protection, however. Further action, such as turning on a cooling fan, is required. The TC622 or TC624, combined with a switching transistor, will turn on a fan at the pre-programmed temperature. Keeping the fan turned off until cooling is required produces several advantages. Reliability is improved because the amount of time that the fan must run is reduced. In addition, efficiency is improved and noise is reduced.

But sometimes turning on a cooling fan is not enough to ensure protection. For example, equipment can still be damaged if the fan fails or air intake vents are blocked. If additional protection is required, the TC620 will control a fan and provide a warning of thermal runaway. A simple circuit can be designed to turn on the fan at one temperature and give an over-temperature warning at a higher temperature. Such a circuit can operate from a single +5 V power supply, so the over-temperature warning is CMOS/TTL compatible.

Summary

Semiconductor thermal sensors offer low and repeatable hysteresis when compared with bimetallic devices. Low hysteresis is very important in protecting critical electronic systems that must be restarted as soon as possible, such as a file server. Since the system will normally attempt a restart operation as soon as the temperature returns to an acceptable level, minimum hysteresis equates to minimum time before the system can return to service.

Silicon-based temperature sensors are easy to interface to the rest of the circuitry and require little or even no additional signal-conditioning circuitry. Understanding the differences between sensor types can help engineers to select the best product for an application.

| Tel: | +27 11 923 9600 |

| Email: | [email protected] |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

| Email: | [email protected] |

| www: | |

| Articles: | More information and articles about Tempe Technologies |

© Technews Publishing (Pty) Ltd | All Rights Reserved