Many people are familiar with Moore’s Law, which states that transistor density doubles every 24 months. This increased processing density has been exploited in the microprocessors used in enterprise desktop and server environments, which have seen tremendous growth in their respective markets. Away from the desktop, electronic devices from handheld PDAs through to command and control systems have seen similar explosive growth, as emerging applications have sought to exploit these new capabilities.

Device manufacturers have tried to stay one step ahead of each other by providing new features to differentiate their products from their competitors. This increasing complexity has required increasing levels of investment, whilst the time-to-market windows have continued to shrink. This has placed enormous pressures on device manufacturers to reduce development timescales, not to mention the financial risk of the investment in the development of product versus the financial returns from its success in the marketplace. If the product development overruns and the product does not enter the market within the window, its success can be greatly diminished. In addition, if the product encounters quality or reliability issues after deployment, the manufacturer's reputation can suffer, and product sales can dwindle rapidly. The Wind River Management Suite was developed to provide advanced technologies to address the problems directly related to these business issues.

Workbench diagnostics: cure for development test migraines

Many engineering development organisations are seeking to use new processor technologies and other semiconductor devices in their designs, which can mean that hardware teams need to prove the operation of these new designs. Sometimes the scarce availability of new silicon can mean that there is a lack of hardware early during the development phase for the software teams to undertake development. This often results in parallel development of hardware and software, which leads to a short and intense integration phase later in the development life cycle. This can present a significant risk to the project development because the later that faults are detected in the development lifecycle, the more expensive they are to rectify.

To reduce the risk that a fault detected during testing will require protracted debugging, advanced development diagnostic tools are required which enable software developers and testers to rapidly pinpoint the causes of faults and to test patches which rectify the problem. Wind River Workbench Diagnostics addresses these needs through the introduction of two runtime technologies: core images and sensor points.

Core images, as the name suggests, provide a snapshot of the system memory and the state of the processor when a fault occurs. The core image can be generated by VxWorks 6.2 when a fault occurs, and the image can be analysed by a developer in the Workbench Diagnostics environment, where they can quickly isolate the root cause of the problem by reviewing the point of execution at source code level where the fault occurred. This precise information enables the developer to quickly determine the cause of the fault, and then fix the fault using sensor points.

Sensor points provide the ability to dynamically patch a running system with new code. This enables developers to rapidly prototype and test possible fixes on a system production build without having to undergo a rebuild of the software or to create a specific debug build which may alter the runtime characteristics of the application. The sensor points can be dynamically enabled and disabled to confirm the absence and presence of the fault respectively, and once proven the sensor point can be integrated into the source code at a convenient point in the product test schedule, rather than having to wait to trial the fix in the next production build. This approach can speed up the time to fault resolution quite dramatically.

Field diagnostics: transforming service delivery

Even with rigorous testing regimes, hardware and software simulation and integration testing strategies, it is hardly guaranteed that all potential hardware and software faults will be detected before the product leaves the factory. As a result, manufacturers are increasingly looking for ways to manage the software in their electronic devices post-deployment in order to provide a means to address software problems which occur in the field, and to provide software patches which enable continued operation.

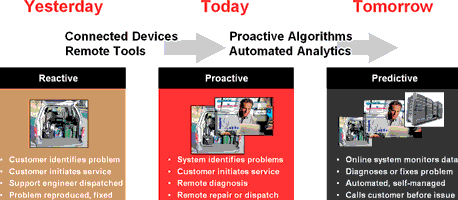

Normally, when a fault occurs in the field, the customer reports the fault to the device manufacturer, and a service engineer is dispatched to investigate and resolve the problem, or the device is returned to the manufacturer for repair. In both cases, this reactive approach is slow and inefficient, and the disruption caused could jeopardise the manufacturer's reputation. However, for some devices, such as space probes, deployment literally is the point of no return, so the ability to manage devices in the field can be essential.

Recent developments have produced the Wind River Field Diagnostics technologies which are transforming service delivery (see Figure 1). These complement the Wind River Workbench Diagnostics technologies by providing the capability to run and manage software deployed on devices in the field. This technology provides a scalable remote diagnostics system which allows support engineers to securely collect and manage operational information from deployed devices. This approach provides accurate information in relation to a fault, which can lead to faster diagnosis and resolution of the fault. This reduces the impact on the customer, leading to improved customer satisfaction.

The next logical step requires a step function change. This involves taking a proactive approach by using automated analytics to monitor systems to enable service engineers to detect trends in system behaviour and to diagnose and fix a problem before it impacts a device. Wind River is investing in the development of technologies to provide these capabilities.

For more information contact Andrew Palmer, Embedded Industrial Solutions, +27 (0)12 547 6071, [email protected], www.eisol.co.za

| Email: | [email protected] |

| www: | www.eisol.co.za |

| Articles: | More information and articles about Embedded Industrial Solutions |

© Technews Publishing (Pty) Ltd | All Rights Reserved