The benefits and drawbacks of conventional lighting technology are well known and documented. In contrast, high-power LEDs are an emerging technology, with the potential to offer enormous opportunities to the lighting market.

With more than seven years of experience in power LED solutions, Future Lighting Solutions provides a comprehensive worldwide LED lighting solutions support structure focused on enabling the adoption of Luxeon-based solid-state lighting. Given that high-power LEDs are so different from conventional light sources, new methods for comparison have been developed and specific standards and regulations are slowly being implemented.

Electrical, optical, thermal

If a lighting solution is designed with high-power LEDs, three areas need to be considered: electrical, optical and thermal. While all three are important, thermal is the most commonly overlooked area and the requirements differ substantially from conventional systems.

From an electrical point of view the forward current, forward voltage and total power consumption all need to be taken into account. High-power LEDs are driven with a fixed forward current, but different LEDs can have a different forward voltage at the same current; therefore, the total power consumption differs. This can be due to manufacturing tolerances, construction processes or simply the differences between LED manufacturers.

From the optical point of view, all high-power LED manufacturers specify the light in lumens, the total amount of light emitted in all directions. There is a direct, non-linear correlation between current and lumens that is published in data sheets.

Finally, there are the thermal parameters which are needed for analysis. Elements to consider are thermal resistance, an indication of how easily heat is conducted through the package, and maximum junction temperature, the maximum allowable temperature of the semiconductor die inside an LED.

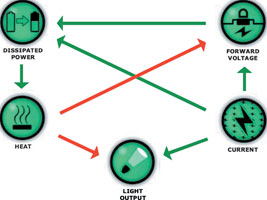

Figure 1 shows the different relationships between electrical, optical and thermal parameters. The green arrows represent direct correlation, while the red arrows represent an inverse correlation. A given fixed current results in a specific amount of light and a specific forward voltage. Multiplying the forward current by the forward voltage equals the total electrical power consumed. Part of this electrical power is converted into light, while the rest is dissipated as heat. This heat can subsequently reduce light output and also reduce forward voltage.

Simulating usable light

In order to calculate what happens in a real-world situation, some iteration is necessary to reach stability, but this is a time-consuming process. A Web-based tool developed by Future Lighting Solutions enables customers to make this kind of analysis with ease.

The Usable Light Tool is available on www.futurelightingsolutions.com, in addition to technical documentation on high-power LEDs, power supplies, optics and other lighting-related issues. Registration is free, and a password is issued immediately, allowing users to analyse and calculate the amount of light produced from a high-power LED in a real-world situation. This tool can, in just a few steps, accurately calculate all the values needed for high power LED analysis and system design. The tool makes it possible to compare two LEDs to see which would be better suited to the simulated operating conditions.

With this information, and the thermal properties of the system, the tool is able to make the analysis. More flexibility is possible and further parameters can be included if required. The tool has been designed with the freedom to modify parameters such as forward current, flux, forward voltage and junction temperature. Entering a value will set the parameters and the tool will use them to make the analysis instead of the default values. This can be useful, for example, when driving the LED from a pre-defined driver for which the forward current is known.

Once analysed, the software tool displays the electrical results such as calculated drive current, forward voltage and power consumption, as well as thermal results and optical results, including flux and efficiency.

Analysing lumen maintenance

Other important aspects to consider when designing an LED system are lifetime and lumen maintenance of the LED; effectively its behaviour over time. For light sources, lifetime is the total period over which this source produces light before a specified cut-off condition is encountered. This is a statistical parameter which is represented by a percentage. In the lighting market the letter B, followed by a number, represents this percentage. For example, B50 would represent the point in time (measured in hours) where 50% of a device population will have met the failure criteria. When evaluating devices that have a very long lifetime, it is more useful to consider what happens during this period.

High-power LEDs, like conventional light sources, experience a depreciation of light output over time. For this reason, the industry has defined another parameter, the lumen maintenance. The lighting market uses the letter L followed by a value that shows the percentage of initial flux remaining. Therefore, L70 means that 70% light output is maintained. Whereas the industry refers to 50% lumen maintenance for traditional light sources, ASSIT (Alliance for Solid-State Illumination Systems and Technologies) recommends 70% for Power LEDs. At 70%, a human observer would not notice a significant change in light output.

Bxx, Lxx graphs are an easy way to give an instant projection of lumen maintenance as a function of the operating conditions of the LED (ie, drive current and junction temperature).

As an example, B50, L70 is the operating time after which 50% of an LED population is likely to reach the 70% lumen maintenance threshold, or 30% depreciation, relative to their initial light output. Alternatively, B10, L70 indicates when 10% of an LED population reaches the 70% lumen maintenance criteria.

Key factors governing the lumen maintenance in high-power LEDs include the construction of the LED (die, packaging and assembly), semiconductor technology (InGaN or AlInGaP) and operating conditions (drive current and junction temperature).

Lumen maintenance figures which do not have clearly specified conditions, or at least the operating current and junction temperature, are questionable and potentially useless to the designer. A decrease in forward current and junction temperature will result in longer B50, L70 lifetimes.

Alternatively, if a B50, L70 of only two or three thousands hours is needed, the LEDs can be driven with higher currents or at higher junction temperatures. The Usable Light Tool can effectively be used in two different ways: Start with the desired L70 timing, then identify suitable current and junction temperature values and use these to predict the output; or calculate the output values and use them with the graphs and Usable Light Tool to determine the overall lifetime of the LED light source.

For more information contact Future Electronics, +27 (0)21 421 8292, [email protected], www.futureelectronics.com

| Tel: | +27 21 421 8292 |

| Email: | [email protected] |

| www: | www.futureelectronics.com |

| Articles: | More information and articles about Future Electronics |

© Technews Publishing (Pty) Ltd | All Rights Reserved