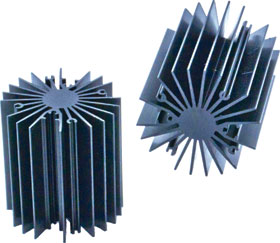

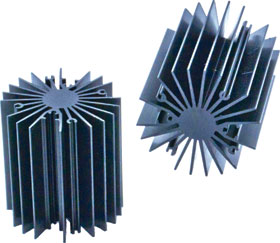

Heatsink extrusions for LED lighting

1 May 2013

Circuit & System Protection

Ohmite Manufacturing is supplying Wakefield Solutions’ 19000 series radial-fin heatsink extrusions for LED light engines.

Developed in conjunction with an engineering team from a leading LED manufacturer, the 19000 series is designed to help LED engineers meet both space constraints and operating parameters. With a low-cost, lightweight aluminium profile, it offers high thermal performance that makes matching the right heatsink to the right LED a much less time-consuming process.

In addition to being black anodised for maximum thermal performance, the heatsinks are also constructed with a radial-fin geom-etry that has been optimised for natural convection. This design is well suited for many types of LED lighting fixtures.

Though 19000 series heatsinks are most commonly used in both recessed and externally mounted downlighting applications, they are equipped with extrusion profiles that suit a variety of LED configurations. Mounting features are in fact incorporated as part of the extrusion, so that the heatsink can be easily mounted with standard hardware.

Each extrusion profile has screw bosses located precisely to enable easy LED substrate attachment, and provisions for slip-nut attachment make it easy to assemble the heatsinks into diverse lighting fixtures.

Wakefield offers five different models of the 19000 series, each designed for a different maximum power rating and expected temperature rise above ambient temperature. Options range from a maximum 14,7°C rise for a 4,5 Watt power rating to a maximum 29,2°C rise for a 42,8 Watt power rating. All models do not exceed a maximum LED substrate temperature of 75°C, and are available in multiple sizes, weights and thermal resistances.

Heatsink lengths range from 50,8 to 190,5 mm, with diameters of 32 to 115 mm, while their weights range from 92 grams to 1199 grams. Available power ratings include 42,8; 26,3; 9; 4,5 and 24 Watts, with corresponding thermal resistances of 0,68; 1,15; 2,38; 3,27 and 1,15 C/W.

For more information visit www.ohmite.com

Further reading:

Clearing the Static: Staying grounded

Actum

Circuit & System Protection

To maintain reliable electrostatic discharge control, regular testing and accurate measurement are essential, with grounding products and ESD testing equipment being vital.

Read more...

Smarter protection without disruption

NewElec Pretoria

Circuit & System Protection

Designed for operations still running without integrated automation, NewElec’s retrofit-friendly systems let you upgrade performance and safety without overhauling your entire network.

Read more...

Circuit breaker for reliable, compliant protection

RS South Africa

Circuit & System Protection

Legrand’s low-voltage power distribution portfolio encompasses the DX3 range of miniature circuit breakers, designed to deliver dependable protection in residential, commercial and industrial installations.

Read more...

Reducing noise on power supply lines

Future Electronics

Circuit & System Protection

Murata has introduced the EMIFIL ESD Series Noise Filters, a breakthrough solution engineered for superior noise suppression and enhanced electrostatic discharge (ESD) protection.

Read more...

Clearing the Static: Fundamental principles of static control

Actum

Circuit & System Protection

Controlling electrostatic discharge in electronics manufacturing is essential with effective ESD programs built on six key principles.

Read more...

Electrical fire safety in lithium-ion battery rooms

Circuit & System Protection

Pratliperl is a non-combustible, ultra-lightweight aggregate that can be mixed with cement and applied as a plaster or screed to walls, floors, and ceilings.

Read more...

Clearing the Static: ESD training in the workplace

Actum

Circuit & System Protection

To protect sensitive electronic components, A structured, consistent, and sustainable ESD training program is essential.

Read more...

Protect your pumps – protect your profit

NewElec Pretoria

Circuit & System Protection

In South Africa’s demanding agricultural landscape, irrigation is not just an essential service – it is the heartbeat of farm productivity.

Read more...

Clearing the Static: ESD and installation: A durable antistatic solution

Actum

Circuit & System Protection

ESD flooring provides a reliable, long-term solution for managing static electricity by safely dissipating static charges through the floor to a designated ground point.

Read more...

Why wait to automate

NewElec Pretoria

Circuit & System Protection

NewElec’s initiative helps you gain operational visibility via HMI or PLC by retrofitting intelligent motor protection relays without replacing MCCs or rewiring the plant.

Read more...