One of the key features that separates a well thought-out industrial enclosure design from one claiming to be designed for the task is its ability to remove heat. Heat is the fiend of the applications engineer - it reduces the overall MTBF of the system; it causes the system CPU(s) to lock or run at a reduced speed; it derates power supplies, damages batteries used for uninterruptible power supply units (UPS) and prevents hard disks from being used.

The text book industrial application sits in an hermetically sealed environment - one in which pollutants never enter, moisture and dust are filtered out and noise and vibration just do not exist. Reality builds a different picture that could almost be alien to the traditional designers of 19" systems. Not all applications are identical and therefore, based on this statement, not all industrially suited systems should look identical.

Traditional 19" off-the-shelf rack designs are constructed of conductive aluminium for optimum heat transfer and EMI shielding, are well-ventilated to allow heat to escape by convection and are readily available. Fan trays for forced air cooling partially alleviate the problem but require frequent maintenance and add to the bulk of the unit. However, the actual real-life problems with heat removal have not been properly addressed - until now.

Inova Computers is a leading manufacturer of high volume, low cost embedded industrial computing solutions based on the 3U CompactPCI form-factor. To justify this claim, a great deal of effort and manpower has been invested to investigate the properties of a well-engineered, conformant, functional and yet affordable industrial 19" enclosure.

Its research has shown that in the real world the working components within an enclosure need to be shielded from their immediate environment. This idea has hermetic overtones, which at first glance makes it unsuitable for use since free airflow is now prevented. Wrong! By dividing the enclosure into separate, compartments heat can be exchanged more efficiently through a combination of forced air circulation and convection cooling without jeopardising space or weight.

These practical results led Inova to develop a range of aluminium Cool Breeze CompactPCI enclosures that are impervious to foreign matter and yet allow EMI-shielded, CompactPCI boards to be fixed in place while still permitting a constant passage of air flow to prevent local hot-spot build-up. In fact, a complete system fitted with two high performance, passively cooled 450 MHz CPUs, power supply, UPS and I/O boards has a 'delta' of less than +5°C compared to the outside ambient.

Operation

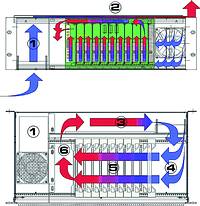

Referring to Figure 1, ambient air is drawn by a fan through the bottom of the enclosure one and forced to the lid where it is guided across the entire surface area two collecting and removing heat as it flows. Chambers 1 and 2 are completely separated from the main chamber. The fan in the main chamber circulates the air 3 by drawing it from behind the backplane and forcing it into a cool air chamber 4 which cools the high-performance CPUs. Due to blocking seals the cool air is forced beneath the first CPU to the second single-slot CPU and then up to the lid. From here it transfers heat to the lid 5 as it flows across all boards and power supply before repeating the cycle 6.

For further information contact Sean van der Walt, Systematic Designs, (021) 555 3866, [email protected]

© Technews Publishing (Pty) Ltd | All Rights Reserved