The manufacturing industry has been one of the most receptive sectors to artificial intelligence and machine learning, especially in electronics manufacturing. There is no denying that the electronics sector has a long history of invention. The sector has frequently shown itself to be at the forefront of technology adoption. Electronics industry experts have identified and highlighted a significant change driven by artificial intelligence in the industry which reveals that using AI in electronic manufacturing has many advantages.

According to a report, by 2030, AI will have a value of about $22,6 billion, at a CAGR of 48,2% in the manufacturing sector. It indicates that AI is essential to the future of electronics manufacturing, and early adopters will benefit from process optimisation, reduced costs, improved product quality, and the generation of fresh ideas that AI offers.

Application of AI to improve the manufacturing process

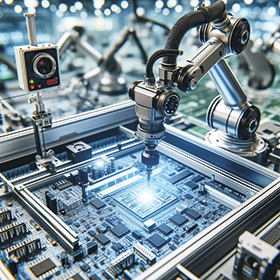

AI in the electronics manufacturing sector can be utilised in almost all processes. For example, AI can help automate the design process by analysing the schematic, and generating a layout that is optimised for performance and manufacturability. AI can also assist in identifying and removing faulty components before they consume further resources. Listed are three ways in which AI can benefit a manufacturing process:

1. Quality control

Quality control is a significant use of AI in the manufacturing of electronics. It involves analysing images and other data from production processes to identify defects and other issues that can impact product quality. Early detection of problems allows manufacturers to limit the quantity of substandard goods that reach the market. Due to its role in ensuring that goods satisfy the high standards of quality that customers want, quality control is crucial to the electronics manufacturing sector.

2. Predictive maintenance

Predictive maintenance is an application of AI that uses data from sensors and other sources to forecast when a machine is likely to break down. Predictive maintenance plans repairs or maintenance before a machine breaks down, thereby minimising downtime and enhancing product quality. This is a crucial component of electronics manufacturing, as it helps avoid costly downtime and repairs that can result from equipment failures.

3. Production process optimisation

One of the most significant benefits of AI in electronics manufacturing is the ability to optimise production processes. By analysing data from machines and other sources, AI algorithms can identify areas where production can be improved, such as by modifying machine settings or changing the order of production steps. In the very competitive electronics manufacturing sector, cost reduction and increased productivity can both be achieved with the help of AI for optimisation.

Challenges of AI in electronic manufacturing

AI is one of the most impressive human achievements that offers endless opportunities in the electronics manufacturing industry. However, certain barriers impeding digital transformation and AI initiatives in this industry need to be overcome.

Lack of skilled workers: Developing and implementing AI systems requires specialised skills and knowledge, which may be in short supply in some organisations. Although AI is often associated with the rise of robotic automation systems, machine learning technologies are constantly advancing. If an inhouse team lacks skilled data scientists, it may be beneficial to seek out AI professionals with the relevant experience.

Data quality: The quality of data used to train AI models is critical to the model’s success. Electronic manufacturing can generate a large amount of complex data, and ensuring its accuracy and completeness can be challenging.

Integration: Integrating AI systems with existing manufacturing processes and systems can be difficult, as it could require significant changes to the organisation’s infrastructure.

Cost: Implementing AI systems can be initially expensive, as it requires significant investment in hardware, software, and personnel.

Regulatory compliance: Electronic manufacturing is subject to a range of regulations and standards, and ensuring that AI systems comply with these regulations can be challenging.

Security: AI systems used in electronic manufacturing may be vulnerable to cyber-attacks, and ensuring their security is critical, to avoid losing critical data or system uptime.

Ethical considerations: The use of AI in electronic manufacturing raises ethical considerations, such as privacy and transparency, which must be addressed.

Overall, these challenges need to be carefully considered and addressed for the successful implementation.

As the industry becomes more competitive, manufacturers need new ways to reduce costs, improve efficiency, and maintain high product quality. AI technologies provide a way to achieve these goals and stay ahead of the competition. Predictive maintenance, quality control, and production optimisation are just a few examples of the applications of AI in electronics manufacturing.

© Technews Publishing (Pty) Ltd | All Rights Reserved