A solder paste’s viscosity and thixotropic properties influence its performance in different production environments. Viscosity is a measure of a fluid’s resistance to flow. Think of it as a fluid’s ’thickness or ‘thinness.’ A fluid that flows slowly, like molasses, has a high viscosity, while one that flows easily, like water, has a low viscosity.

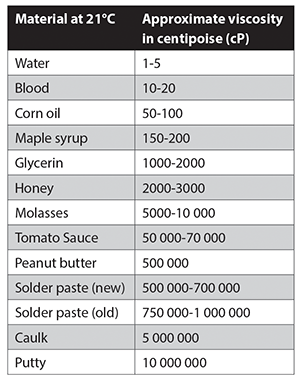

For reference, Table 1 shows the typical viscosities of various liquids.

Thixotropy is a property unique to certain non-Newtonian fluids. It describes how a fluid’s viscosity changes under applied forces, but gradually recovers when the stress is removed. (The difference between Newtonian fluids and non-Newtonian fluids is that the former maintains a consistent viscosity regardless of applied forces.)

Wall paint is an example of a thixotropic non-Newtonian fluid. The paint thins when force is applied during the brush or roller stroke for ease of flow and to fill imperfections, but quickly thickens to prevent runs and drips once the force is removed.

Solder paste printing is much like paint in this way. The squeegee blade applies a shear force as it rolls solder across the stencil. This temporarily reduces viscosity, allowing the paste to flow and fill the stencil apertures. Once the force is removed, the solder paste thickens, maintaining the shape of the apertures after the stencil is lifted.

High volume production: The need for consistent viscosity

In high-volume, high-throughput production, rapid application processes require solder pastes capable of withstanding high print speeds and higher squeegee pressure. This creates greater shear forces on the paste, helping it flow into the stencil apertures, but also demands that it return to its original thickness quickly.

A paste that is too thick may not shear thin adequately, leading to incomplete aperture filling or excessive stencil cleaning requirements. Conversely, a paste that is too thin may spread or slump, causing bridging or solder balling. Thus, for high-volume lines, a solder paste with a balanced initial viscosity and responsive thixotropic behaviour is optimal.

High-mix environments: Leveraging thixotropic properties

In high-mix environments, where PCB layouts are diverse and production runs are shorter, the flexibility of solder paste becomes a key factor. Thixotropic properties allow the paste to adjust its viscosity based on the shear forces applied during printing. This adaptability ensures that the paste performs well across a wide range of conditions, from low-speed, low-pressure applications to scenarios requiring rapid deposition.

In such environments the ideal solder paste has stable thixotropic properties, offering a wide process window to accommodate different squeegee speeds, pressures, and stencil designs without compromising transfer efficiency or first-pass yields.

Figure 1 illustrates the response of two different solder pastes under shear forces. Paste A has a higher initial viscosity that decreases more significantly under shear stress. This behaviour suggests that while Paste A may perform well under specific conditions, its narrower process window could limit its effectiveness across varied production scenarios.

Paste B has a lower initial viscosity and less pronounced thinning under shear forces. This offers more consistent performance across a wide range of print conditions, which is often most desired for modern solder pastes.

Practical tips for managing solder paste viscosity

Selecting the right paste for the job and adjusting process parameters helps achieve the best results. This requires understanding the specific needs of your production environment and the capabilities of available pastes.

• Do not assume low initial viscosity is an indicator of poor quality or slump. Many newer formulations are ‘wide-window’ pastes with more stable thixotropic properties.

• Visual assessments of viscosity are obsolete. If viscosity is used as an incoming screening procedure, it should be measured on a viscometer and compared to the manufacturer’s specification.

• Reconsider the use of paste conditioning/mixing equipment. These machines usually spin or oscillate the solder paste to shear thin the paste before printing. Pastes may not recover their original, intended properties after this process.

| Tel: | +27 31 822 8555/6 |

| Email: | [email protected] |

| www: | www.truthelectronics.co.za |

| Articles: | More information and articles about Truth Electronic Manufacturing |

© Technews Publishing (Pty) Ltd | All Rights Reserved