The benefits of using X-ray technology in the electronics industry to inspect printed circuit board assemblies are well proven.

This article summarises X-ray radiation dose, and the techniques that can be employed to reduce radiation exposure to samples in a Nordson Dage Quadra X-ray inspection system.

Quadra X-ray geometry

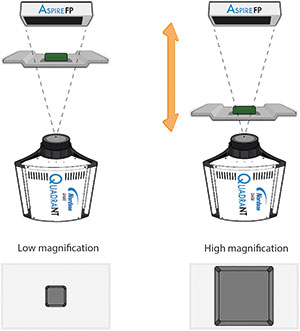

First we need to consider how the Quadra X-ray inspection system works. Quadra allows the internal structure of samples to be seen by shining X-ray light through a sample (Figure 1). This creates a shadow image that is detected in real-time using a high-resolution Aspire flat panel X-ray detector. The darkness of the shadow cast by any point in the sample depends on how much X-ray light has been absorbed by that part of the sample.

High image magnification is used to see smaller features clearly. This is achieved by moving the sample closer to the X-ray tube. For the highest magnification, the sample tray is lowered to the top of the X-ray tube.

Viewing the sample from different angles allows more defects to be observed. The Aspire flat panel detector moves around two oblique axes to allow this. X-rays from the QuadraNT X-ray tube are emitted over a wide cone angle so there are plenty of X-rays available off-axis.

Different materials absorb radiation to differing degrees (Figure 3). Lead is very good at absorbing X-ray radiation which is why it’s used to shield the X-ray cabinet. Silicon and aluminium are relatively poor at absorbing X-rays so images tend to be very bright. Tin and copper, commonly used in solder, are somewhere in between.

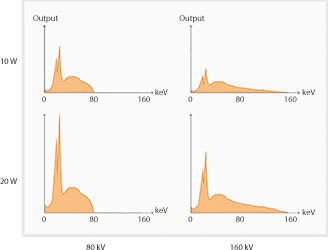

The shadow created at any point also depends on the voltage and power used to drive the X-ray tube (Figure 4). An X-ray tube operating at a voltage of 80 kV creates X-rays over the entire energy range up to 80 keV. Increasing the voltage to 160 kV doubles the X-ray output energy range from 80 keV to 160 keV.

Increasing the tube power increases the number of X-rays emitted at every point over the range. In general, higher energy X-rays are more likely to pass through a sample than lower energies. High energy beams are useful for looking at thick samples, or materials that strongly absorb X-rays, for example lead. Lower energy X-rays are better for thinner samples, or materials that weakly absorb X-rays, for example copper or silicon.

What is X-ray dose?

The X-ray dose for any part of the sample is a measure of the X-ray energy absorbed per unit mass, and is measured in units of gray (Gy), where

1 Gy = 1 J/kg = 100 rad.

Since different materials absorb incoming X-rays with differing efficiency, their absorbed dose will vary when placed in the same X-ray beam. A material like lead, which absorbs X-rays well and casts a dark shadow in an image, will absorb a higher dose than a material like silicon which absorbs X-rays weakly.

The absorbed dose also varies with:

• Distance to the X-ray source: The amount of X-ray radiation reduces as 1/r² in the same way a light appears brighter the closer you are to it.

• Time in X-ray source: X-ray dose is cumulative so the longer spent in the X-ray beam, the higher the absorbed dose.

• X-ray tube output: The higher the tube power or voltage, the larger the absorbed dose.

How to reduce sample dose

Reducing the magnification used and minimising the time the X-ray tube is switched on are effective ways to reduce X-ray dose. Quadra’s low dose mode can be used to switch X-rays off when it detects the sample is no longer being manipulated.

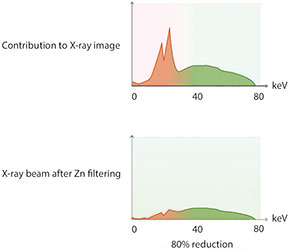

Another method is to filter out lower energy X-rays (Figure 5). These X-rays do not contribute to the final image for two reasons:

• Absorption by sample: At low energies, particularly below 20 keV, X-rays are strongly absorbed by most samples. They contribute to sample dose, but are less likely to make it through the sample to the X-ray detector.

• Detector sensitivity: Flat panel X-ray detectors, like AspireFP, are insensitive to X-rays below ~20 keV. Any X-rays that manage to pass through the sample have a lower likelihood of being detected.

Filtering out low energy X-rays is an effective way to reduce sample dose without compromising image quality. A filtering sample tray is available for Quadra which incorporates zinc strips to absorb low energy X-rays while letting higher powers pass through to the sample. This can reduce overall X-ray dose by up to 80% (Figure 6).

Masking is a simple way of reducing X-ray dose for any components on a board that do not need to be inspected at all by X-ray. A portion of dense material, for example lead, can be attached to the sample tray immediately below the sample to mask the sensitive component from X-rays.

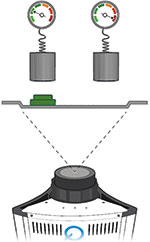

Quadra includes a dose calculation tool that tracks the average dose acquired by the whole sample during inspection. For the most accurate results, the tool can be calibrated by measuring X-ray dose in the path of the X-ray beam before and after the sensitive component (Figure 7).

Getting better images from thin samples

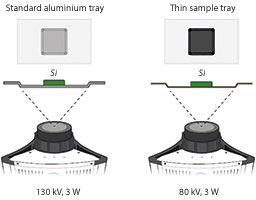

High energy X-rays are poorly absorbed by thin samples, or by weakly absorbing materials such as silicon or aluminium. Medium energy X-rays give the best image contrast for these samples. However, these energies are typically between 30 and 80 kV and are attenuated by ~90% by the standard aluminium sample tray.

A thin sample tray is available for Quadra which is manufactured from a thin layer of carbon fibre instead of a thicker layer of aluminium. This allows 10 times more medium energy X-rays to pass through, creating clearer images with better contrast.

| Tel: | +27 11 869 0049 |

| Email: | [email protected] |

| www: | www.mykaytronics.co.za |

| Articles: | More information and articles about MyKay Tronics |

© Technews Publishing (Pty) Ltd | All Rights Reserved