The changing requirements of customers, new products and new materials – especially refractory compound alloys – demand a shift in thinking for reflow soldering.

Whereas four heating zones were absolutely enough to produce a good reflow temperature profile with a low delta T, lead-free compound alloys represent a new challenge and more flexibility is therefore demanded for identical lengths of heating zones and machines. The same thing applies to cleaning the process gas. The noticeably increased process temperatures in the lead-free soldering process inevitably lead to higher rises in evolutions of exhaust gas, eg, from the paste, components, solder resist and conductive material, as well as from the reactive products of these substances. This background inevitably leads to decisive changes in the plant engineering and process engineering of modern reflow systems.

SEHO introduced its new 'MaxiReflow' reflow soldering system for the first time at the 'Productronica 2005' trade fair, after a developmental phase of almost two years. The objective when developing this new oven was to take account of the new requirements and to take a further step beyond that. However, something that had been positively proven in theory and in lab tests, still had to be verified in practice. A demanding partner was found in the firm of RAFI, which has put the MaxiReflow system through its paces in a three-stage operation during recent months.

RAFI uses the most modern systems inhouse for developing and manufacturing the products that its factories produced by the millions each year. CAD systems support the design engineers and the precision parts are manufactured on CNC-controlled machines. Concurrent engineering guarantees optimal results because the production planning and quality assurance have been integrated into a product's developmental phase already.

The methods of production are orientated to meeting both the economical and ecological standards. The objective is to achieve a defined standard of quality with optimal economic efficiency as well as a high degree of environmental compatibility.

Unique transport system

MaxiReflow's new 'LowMassConveyor' transport system has shown itself to be extremely innovative and unique worldwide.

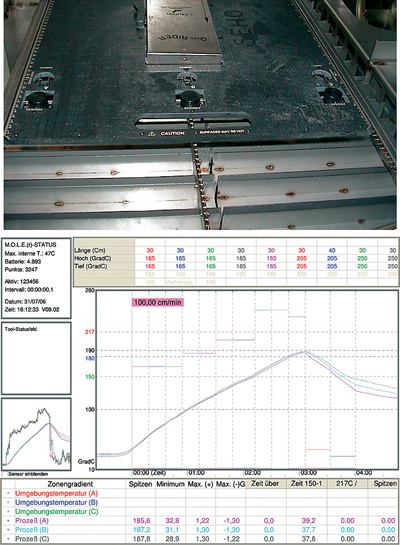

The chain guide profiles are carried by continuous steel cables in this transport system; each of which is pre-stressed with a tensile force of 1,5 metric tons through the entire system. This ensures that the chain guide profiles are aligned absolutely parallel. The extremely thin chain guide profiles are 'thermally invisible' and so can be used at the same time. A similar principle is used for the central support, which also cannot be 'seen' on the temperature profile (Figure 1). Both the carrier transport system and also the central support represent a minimum thermal mass and so they do not offer any resistance to the flow of hot gas within the oven.

This innovative transport system has a further advantage in respect of maintenance. Only one spindle mechanism is required within the process zone because the parallel alignment of the chain guide profiles is not achieved within the oven by spindles, but solely by means of tensile force from the pre-stressed cables. This method results in less potentially-corroding surfaces onto which the contaminated process gases can condense: this reduces to a minimum, the outlay on maintenance and the extent of possible wear.

This new concept also convinced the judges in their award of the internationally recognised 'Global Technology Award 2006' where they evaluated the MaxiReflow system as the most innovative soldering system marketed in 2006.

Effective heat transfer is demanded

The heat transfer's effectiveness is one of the most important criteria for modern reflow soldering systems. It generally applies that the lower the oven's set temperature, the lower is the thermal stress on components and the carrier's materials: the rate of oxidation is correspondingly lower too.

Additionally, the reflow soldering system's flexibility plays an important role because the lead-free soldering process offers less scope for potentially defective influences, on account of the shorter processing time. Systems that have a sufficient number of zones - especially in the peak area - are definitely one step ahead in this case.

A MaxiReflow 3.6 system, which comprises over seven preheating zones and five peak zones, has been evaluated at RAFI in Ravensburg. These multiple peak zones offer the opportunity of influencing the time via the liquidus and the delta-T on the carrier, without changing the oven's other essential parameters like the transport speed or preheating temperatures for example.

The new MaxiReflow system incorporates the proven tangential fan technology of the FDS MaxiPower series. A high volume of recirculating gas along with moderate flow speeds ensures very efficient and homogeneous heat transfer to the flat assemblies. Work can thus be done at comparably lower entering temperatures, which complies with the present requirements for a short processing period in lead-free soldering processes. All of the components are soldered reliably, while the thermal stress - especially on components of low mass - is reduced noticeably.

"Minimising the delta-T plays a primarily important role for RAFI inhouse", explains Bernd Spahlinger, who is responsible for the Process Technology division at RAFI. "Areas of greatly-varying thermal masses can be found on many of the assemblies which need to be processed. These varying thermal masses make it difficult to guarantee a suitable soldering environment for all areas of the assembly" he further explains. "However, very good results can be achieved in this case by means of the 'multiple peak' principle".

The temperature setting for the Maxi-Reflow system at RAFI in the first peak zone is chosen to be higher than in the following peak zones, in order to achieve the lowest possible delta-T. It is important for this purpose, that a rising gradient of 3°C/s max. should be taken into consideration. A delta-T of 18,5°C has been achieved with the tested assembly by means of this process. This temperature difference was measured between the PCB surface and a high-mass copper coil. However, a delta-T of only 25°C was able to be achieved in a competitor's reflow system with the same heating area length but a lower number of zones.

"The maximum temperature in the peak area, is one of the Multi-Peak system's further noticeable advantages," explains Spahlinger. "A flat peak can be produced by means of controlling the individual zones separately. The soldering time can be varied via the liquidus, without raising the maximum temperature in the peak, which signifies a lower temperature stress for the assemblies in the end."

Efficient gas cleaning process saves

An efficient condensate management system with cleaning of the process gas is an absolute must for a modern reflow soldering system, in order to ensure that the steam which inevitably results does not condense within the process area or on the products to be processed.

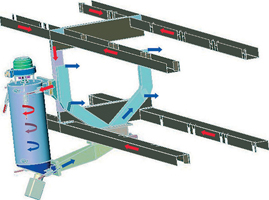

The MaxiReflow system that was tested at RAFI is equipped with a further developed system for cleaning the process gas, which enables long maintenance intervals to be achieved. A new feature for this purpose is that all of the heated zones are directly connected to the system for cleaning the process gas. Moreover, the removed process gas is conducted within the hot area up to the cleaning point, in order to guarantee that the condensation is controlled. The cleaning system itself is the first cold point that the process gas - which has to be cleaned - meets: a thermally-conditionable condensing cyclone (Figure 2).

Physically well thought out indeed: but is it suitable in practice? The employees were given the 'instruction' not to clean the soldering system on the test system's installation at RAFI. A hardness test was intended to indicate whether SEHO's process technologists had been correct with their physical calculations and laboratory tests.

The MaxiReflow system was scrutinised for the first time after 1160 operating hours (this corresponds to about 10 weeks of production time) without cleaning and with 26 300 carriers; most of which had a format of 340 mm square with six panels. Not only SEHO but also RAFI were satisfied with the result. The collection sump in the condensation cyclone was up to 90% full (Figure 3). The cyclone's inner walls were covered with a layer of deposited residues about 7 mm thick, which were easily removable with an industrial vacuum cleaner. There was something much more important however: the heating zone had hardly any residues at all and it was absolutely clean. Residues were only found in the inlet tunnel (Figure 4) but this has been provided with a non-stick coating and is easy to clean.

The residues in the cooling module also showed that they could be removed with the industrial vacuum cleaner. The condensation cyclone had fulfilled its function well. The efficiency would be somewhat reduced whenever the covering on the walls is thicker because the residues have a thermally-insulating effect. The cleaning interval must therefore be adapted to the circumstances. Currently the cleaning is done cyclically every four weeks at RAFI. The cleaning of the cyclone is done quickly and the residues accumulate in a very concentrated fashion. As every electronics manufacturer has to deal with problematic waste, then, it makes sense to have as little as possible.

© Technews Publishing (Pty) Ltd | All Rights Reserved