To avoid problems with micro cracks and delaminating during the processing of electronic components, it is necessary to take appropriate storage into account.

Since the introduction of lead-free soldering and the higher processing temperatures involved, the consequent vapour pressure within components increases considerably (up to 30 bars).

Manufacturers deliver these sensitive components in effective protective packaging to avoid absorption of humidity during transport and storage. After opening the package, the countdown begins and the components start absorbing humidity. Depending upon ambient humidity and temperature, the components can be safely used only within a limited time period. This time period is classified by the IPC/JEDEC J-Std 033B.1. When a component has exceeded the allowed exposure time, the humidity can be decreased through a baking process, after which the component should be processed immediately.

Repeated absorption of humidity must be avoided, because although the standard allows a second baking, the process induces oxidation. This in turn reduces the wetting ability of the connection surfaces. To fight this well-known effect, many suppliers of drying ovens provide an additional reduction of oxygen by means of a nitrogen atmosphere or vacuum during the drying process. Setting the clock back to zero for the component can take as long as 48 hours, inevitably bringing about considerable costs for nitrogen, and only a low rest-oxygen content of less than 13 ppm stops the oxidation.

Because of the considerably higher content of tin in lead-free soldering alloys, the need to consider oxidation protection during storage has increased in importance. This is caused by higher oxidation percentage of these alloys and the generally worse wet ability and flow properties of lead-free soldering alloys.

The oxygen causing the oxidation originates from two different sources. The first is the oxygen molecule O2, found worldwide in our atmosphere. However, because of its atomic bond it only occurs at temperatures higher than 40°C. The second and in fact more aggressive bearer of oxygen is the water molecule H2O, in which the oxygen atom is only weakly connected, and a considerable oxidation percentage can already be observed at low temperatures. This means that over and above the content of oxygen, the content of humidity is an even bigger contributor to the oxidation percentage in stored components.

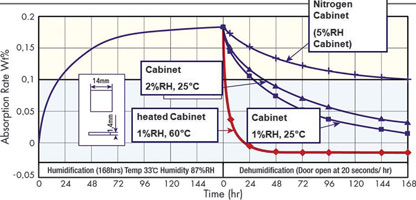

Technically it is possible to solve both problems at the same time. However, it is important to avoid heating above 40°C thereby eliminating the air-oxygen as reaction partner, and to provide strong dehumidification of the air at the same time. To achieve this, dry storage systems have been designed that can produce internal atmospheres of below 1% RH. Only by this extremely low content of humidity it is possible to protect not only the components against the additional absorption of moisture, but also to remove the moisture already absorbed within the packaging of the components. As the accompanying graph below shows, even storage in very clean nitrogen does not provide actual dehumidification of components, as levels under 0,1 Wt % are not possible.

When considering how the speed of diffusion affects the drying of components, the variables of concentration and temperature are decisive. Ultra low humidity desiccant cabinets are now available that can sustain a low rest-humidity of <1% RH and the latest technology even provides recovery times (after door openings) of less than one minute. This thereby offers not just safe storage but effective drying of components, even at room temperature. This is impossible to achieve with nitrogen alone. Components stored in ultra low RH cabinets utilising such technology are thus at the same time dehumidified and prepared to be processed.

By virtue of the oxidation protection explained previously, longer periods of storage without the use of moisture barrier bags are also practical.

For more information contact Shanelo Technologies, +27 (0)74 319 6785, [email protected], www.shanelo.co.za

© Technews Publishing (Pty) Ltd | All Rights Reserved