In any process there are always opportunities to improve, reduce the number of process stages or reduce the cost of manufacture. Each may not improve yield initially, and may even increase manufacturing defects, but it must in time benefit some companies’ processes or products.

Engineering is always looking at alternative processes and simultaneous double sided reflow soldering (SDSRS) is a possible new candidate for investigation. It has been used by two Japanese companies, one large computer manufacturer in the USA and is reportedly being used by one other company in Europe. It was originally patented by one large US producer.

Process sequence

The process of SDSRS includes the following stages:

* Stencil print solder paste: Side One.

* Dispense adhesive: Side One.

* Alternatively screen print adhesive: Side One (using recessed stencils).

* Alternatively dispense paste and adhesive.

* Place components: Side One (possible UV curing stage for adhesive).

* Invert board.

* Screen print solder paste: Side Two.

* Place side two components: Side Two.

* Possibly insert through-hole components.

* Reflow solder both sides simultaneously.

The question has to be asked: why consider SDSRS as it will undoubtedly cause problems with loss of components in the early stages of process development? If we examine the time taken for the reflow cycle of a product, typically this is 3 to 4 minutes. By reflowing both sides of the assembly, the total time is then 8 minutes. Clearly, by conducting simultaneous reflow, the process cycle time is reduced, with time saved on the total process cycle.

It used to be the case that placement was the slowest part of the process but with increasing speeds this is not the case. Printing was the last part of the process to be attacked by the speed merchants focusing on the solder paste specification which was the limiting factor in high-speed printing. The formulations of paste have now provided the speed to make other parts of the process the weak links in the chain with cycle speeds for printing being less than 10 seconds per board.

Advantages of SDSRS

Eliminates one reflow process stage

With simultaneous reflow soldering, both sides of a surface mount board can be conducted in one operation. If through-hole parts are also designed to be reflowed, this can be done in a single operation.

Only one heating process for double sided boards

With only one heating process there is a potential benefit to the reliability of the joints with a thinner intermetallic formation being possible. The issues related to reduction in solderability of surface mount pads are also eliminated.

With only one heating process during reflow soldering, in which the board may be supported with a central wire, it is possible to reduce warpage of boards susceptible to this problem. No hold time between reflow cycles means there are less issues of moisture with PCBs and components.

Reduction in capital equipment

Eliminating a reflow process means one less piece of equipment in a production line is required. The cost of power consumption and extraction systems for reflow equipment is higher than any other piece of equipment on the line and they are effectively halved.

Reduced floor space requirements

Eliminating a reflow oven reduces the floor space required in a manufacturing area. Even with the need for an additional printer or the use of a single dispenser for both adhesive and paste, floor space is still being saved.

Reduced handling stages

The number of handling stages is reduced compared to a conventional surface mount process, albeit only slightly reduced from a fully double-sided reflow process.

Increased PCB throughput speed

The total process cycle time for each product is reduced by the elimination of one reflow soldering stage. The increased cycle time for one printing or dispensing stage is still far less than the period taken to reflow one side of a board.

Potential elimination of component weight issues

In a liquid state there is a limit to component weight during traditional double sided surface mount assembly. Large heavy components can fall off the board. If adhesive is used and cured, it will increase the range of components that can be used on both sides of the board.

Improved solderability of OSP circuit boards

There has been great debate on the benefits of using OSP: improved printing and placement, cost reduction and improved yields. OSP coatings have been shown to deteriorate during two reflow cycles; with one reflow process stage the problem is eliminated. It is the opinion of the author that most of the problems seen on OSP coated boards stem back to the quality or preparation of the original coating. Potential users of OSP should understand some of the simple process evaluation techniques or goods receipt tests.

Disadvantages

Of course, no process is perfect, and there are certainly disadvantages to SDSRS.

They are:

* New process introduction.

* Possible loss of components.

* Gluing stage required.

* New glue materials required.

* Glue curing process.

* Possible limits on component positioning.

Examples

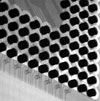

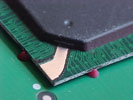

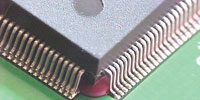

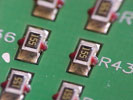

Figures 5 to 8 illustrate examples of joints produced with this process and tin/silver/copper solder paste reflowed in a single convection cycle in air.

For more information visit www.askbobwillis.com

© Technews Publishing (Pty) Ltd | All Rights Reserved