Tips for detecting counterfeit components

17 October 2012

Manufacturing / Production Technology, Hardware & Services

Bob Willis

In an ideal world, components would only be purchased from the original producer, a franchised distributor or an approved non-franchised source. However, this is not an ideal world. With the majority of components being counterfeited falling in the $1 to $10 range, this is a problem for all.

A simple approach to minimise counterfeit components passing through goods receipt to production is to create a component reference database so that reference components and images of known good components can be used for future comparison.

The following should be considered by engineers for inclusion in their company database. Reference component details should be obtained when a component is known to be going obsolete, on long lead times, difficult to obtain or found to be in circulation as a counterfeit product. Using a spreadsheet provides a simple way of storing data and links to other information.

Where components are being used in existing products or being considered in new products that are single source or subject to long lead times, they should be added to the component database. Where components are considered to be high risk, are knowingly purchased from a new source or the supplier has not been previously qualified, reference samples must be obtained for review and possible testing.

A golden board assembly is often held in manufacture as a reference for build quality or as an inspection reference and could be used by goods receipt staff. This is an ideal solution for OEM and also provides confidence for contract assembly staff as a working product is always the best reference.

X-ray inspection is a very powerful tool to examine a component or a batch of components without taking them out of their protective packaging. X-ray allows the lead frames, die size, bond wire type and package type to be identified. Figure 1 shows components inspected without opening the sealed MSD bags.

Figure 1. Components can be inspected by X-ray without removing them from their MSD packaging.

A guide to inspection of plastic ICs can be conducted by production staff after some hands-on training and a reference guide can be created for counterfeit avoidance with samples such as those in Figure 2.

Figure 2a. Genuine sample with pronounced moulding nodules.

The surface of the component body should be inspected: all surfaces should have a similar surface appearance and reflect light in a similar manner. If a surface has been modified/ground to remove previous marks there will be a difference in the surface, particularly around the markings. Figure 2b shows how the sharply defined moulding nodules have been flattened.

Figure 2b. Counterfeit component with ground-down surface.

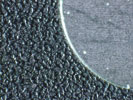

Any modification to the surface may change the appearance of surface features like moulding marks, laser marks and pin dimple indicators when compared with reference samples. In Figure 3, the surface of the plastic is as produced with sharp edges to the mould contours and no scratching on the surface of the mould contours.

Figure 3. Genuine component shows sharp edges to the mould contours and no scratching on the surface.

A reference source/photo guide should be compiled of existing qualified manufacturers’ logos, packing labels, SMT reel labels and outer packing labels for use at goods receipt inspection. This may take time to compile but the sooner one starts, the better future problems are prevented.

Manufacturers should select and appoint an independent laboratory to conduct component testing when specialist tests may be required for independent verification. It makes sense that when someone is needed on call for support, company approval and financial issues have already been sorted in advance.

For more information visit www.bobwillisonline.com

Further reading:

Yamaha reveals software innovations to boost printing, mounting, and intelligent factory

Truth Electronic Manufacturing

Manufacturing / Production Technology, Hardware & Services

Yamaha Robotics Europe SMT Section has added new features to native equipment software and Intelligent Factory tools that accelerate equipment programming, increase production efficiency, and enhance factory productivity.

Read more...

UltiMaker introduces defence-grade 3D printing

RS South Africa

Manufacturing / Production Technology, Hardware & Services

Leading at launch are the UltiMaker S6 Secure and UltiMaker S8 Secure, two robust solutions designed to deliver trusted and reliable, on-demand production capabilities.

Read more...

The future is built by hand

Manufacturing / Production Technology, Hardware & Services

Choosing a trade or technical path does not just open doors for your future self. It opens doors for the people you will serve, the systems you will maintain, the businesses you will grow, and the communities you will strengthen.

Read more...

September exclusives at PCBWay: Big savings on PCBs and 3D printing

PCBWay

Manufacturing / Production Technology, Hardware & Services

[Sponsored] This September, PCBWay is bringing you two exciting, limited time offers that showcase both style and versatility. Whether you are designing with PCBs or prototyping with 3D printing, these will help you create more while spending less.

Read more...

Understanding solder paste viscosity and thixotropy

Truth Electronic Manufacturing

Manufacturing / Production Technology, Hardware & Services

A solder paste’s viscosity and thixotropic properties, a measure of its resistance to flow, influence its performance in different production environments.

Read more...

Global electronics trade in an age of disruption

Manufacturing / Production Technology, Hardware & Services

Governments should invest in domestic strengths, coordinate with international partners, and align trade and industrial policy with the realities of a globally connected electronics sector.

Read more...

The new tool design of IWISS

Startech Industrial

Manufacturing / Production Technology, Hardware & Services

Rooted in IWISS’ dedication to reliability, comfort, and efficiency, the company’s new design refresh elevates craftsmanship by incorporating a rich cultural influence.

Read more...

Strategic collaboration to advance industrial robotics training in South Africa

Manufacturing / Production Technology, Hardware & Services

Yaskawa Southern Africa has announced a strategic collaboration with Sol-Tech, a private vocational training institution based in Pretoria, to strengthen technical education in industrial robotics.

Read more...

Filling high-end PCB manufacturing gaps to accelerate AI electronics growth

PCBWay

Manufacturing / Production Technology, Hardware & Services

[Sponsored] In the digital era, AI and big data technologies are developing at a rapid pace. PCBWay is continuously advancing its PCB manufacturing technology to support the growth.

Read more...

Microtronix revives defunct cell phone plant

Microtronix Manufacturing

Editor's Choice Manufacturing / Production Technology, Hardware & Services

In a significant move for South Africa’s struggling electronics manufacturing sector, local technology firm Microtronix has breathed new life into a formerly defunct cell phone manufacturing facility.

Read more...