Industrial control systems universally employ 24 V DC for their field supply voltage. The presence/absence of power supply voltage is commonly signalled by LEDs found on equipment, like the controller head unit, as well as I/O and communication modules.

LED supply lights aid in minimising installation, maintenance, and downtime in industrial systems/subsystems such as programmable logic controllers (PLCs) and distributed control system (DCS) controllers, power-supply units, sensors, and actuators. Supply LEDs should light up when defined conditions are met, like voltage being in the required operating supply range. Despite their conceptual simplicity, real implementations are not that trivial. They require voltage comparators with hysteresis, need to be self-powered, and must drive LEDs consistently.

Further requirements for such circuits are:

• Low power dissipation.

• The light must be off when the supply voltage is under the minimum operating voltage.

• The light intensity should be invariant of supply voltage.

• The circuit should be tolerant to over voltages.

• Robustness to miswiring, like negative voltages as encountered during reverse polarity.

• Simple circuits can exhibit significant dependence on component, temperature, and voltage variation.

This LED driver circuit is based on repurposing an industrial digital input chip for a function different from its originally intended application. Industrial inputs, as commonly found in industrial control systems, are based on 24 V logic and have clearly specified input current/voltage characteristics with defined input threshold voltages. A sinking input (occasionally called a p-type input) has a pull-down current specified to be larger than 2,0 mA at the maximum input high threshold voltage of 11 V for Type 3 inputs, the most common industrial input type. To minimise power dissipation, today’s digital input circuits limit and tightly regulate the input current to a level just slightly above the 2,0 mA limit.

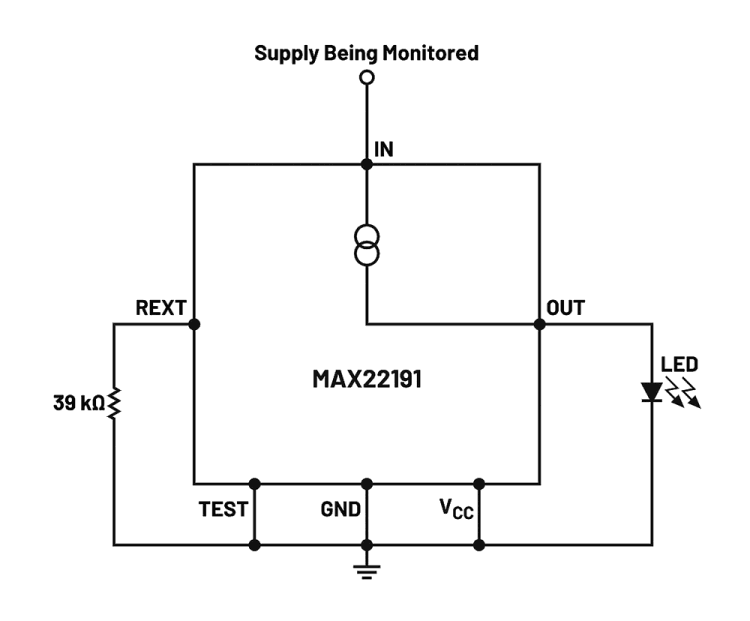

Noticing that the 2,0 mA level coincides with common LED drive currents and that industrial digital inputs have clearly defined switching thresholds, raises the question whether a chip, like the MAX22191 single-channel digital input, would be suitable for power supply monitoring and LED driving. This industrial input device is designed to drive an opto-isolator via its OUT pin. Figure 1 shows the proposed application circuit. REXT is a current-setting resistor, allowing the OUT current to be set in the 2,0 to 2,6 mA range.

The internal current source has a tolerance of ±12,5% over temperature, input voltage, and part to part, ensuring low power dissipation and negligible light intensity variation over supply voltage. With the current source specified OUT output voltage compliance of 5,5 V, it is possible to drive most modern LEDs. The device’s 110 µA (typ) supply current ensures low power dissipation of the solution.

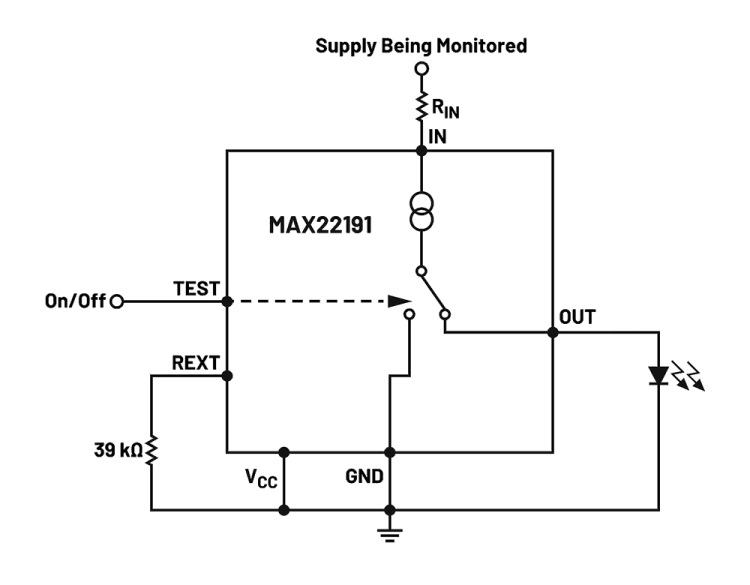

In operation the LED current turns on sharply at 9 V (typ) and turns off at 8 V (typ), providing 1 V hysteresis. The max-on and min-off threshold voltages are specified in the MAX22191 data sheet. Should higher threshold voltages be required, a resistor can be placed in series with the IN input, RIN (see Figure 2). The RIN value is calculated as RIN = (threshold voltage increase)/IIN.

LED control

For application cases where the LED needs to be turned on/off under logic control, the TEST input can be conveniently used, as shown in Figure 2. This allows implementing auxiliary functions like power-up delays, blinking, or other status feedback.

The solution is specified for use over the -40 to 125°C operating temperature range. The IN supply voltage is tolerant to a wide voltage range of -70 to 60 V, which provides headroom for surge protection and robustness to reverse polarity miswiring. In the event of reverse connection, the circuit has a low 1 µA input current in case of a negative input voltage.

Conclusion

The MAX22191 provides a simple means for LED power supply indication applications. Its SOT23 package and low power current-setting resistor constitute a small solution size.

| Tel: | +27 11 923 9600 |

| Email: | [email protected] |

| www: | www.altronarrow.com |

| Articles: | More information and articles about Altron Arrow |

© Technews Publishing (Pty) Ltd | All Rights Reserved