Embedded vision systems are becoming part of everyday life. The development of autonomous cars has caught the headlines, and the use of visual systems will play a key role in their future success. Embedded vision, combined with other sensors, provides guidance for the vehicle. Systems such as lidar (light direction and ranging) measures distance, and the embedded vision systems then provide object recognition. With this technology, the vehicle is able to identify potential obstacles and react accordingly.

The automotive industry, with its headline-grabbing developments, represents the most public example of embedded vision systems for collision avoidance. However, the same technology has a range of applications in the industrial world. As operators are employing more autonomous robots in the factory environment, the need for collision avoidance grows. Embedded vision systems allow factory robots to identify potential hazards and act in the most appropriate way. This keeps the factory safe, while maintaining the best possible efficiency.

Embedded vision systems also have applications within the area of machine safety. The task of providing safe working areas continues to grow in complexity as manufacturing plants become more flexible. Not only do machines have to detect possible hazards, but it is also vital for them to understand the nature of the hazard in real time, so that the right action can be taken to prevent accidents. It is only with the sophistication of modern embedded vision systems that this has become truly possible.

Embedded vision systems also bring benefits to an efficient production line. On any production line, one of the key tasks is quality control. If the only source of quality control is manual inspection, manufacturers are forced to choose between random sampling or 100% inspection. The first method tries to predict the quality of the entire batch based upon a random selection of products. This process introduces fewer delays, but can risk the release of faulty products if the sample is too small. The alternative, 100% inspection, is considerably slower and therefore makes the process more expensive.

Integration into the Smart Factory

As a solution, the sophistication of modern embedded vision systems allows automated, 100% visual inspection. Each item can be imaged by a dedicated camera and compared to the standard in real time. The result is that faulty products can be identified immediately and discarded (or retained for further analysis). This immediate inspection also provides important data that can be used to understand maintenance needs and even predict future failures.

This use of data is at the heart of the smart factory concept. For example, vision systems might identify a rising trend in faults from a moulding machine, which could suggest the need for corrective maintenance. This information can be correlated with other data collected from the same machine, including temperatures and energy consumption. By analysing all the associated data, the maintenance of the machine can be planned before a major failure occurs, which in turn minimises the disruption to production.

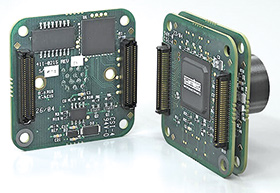

Embedded vision systems are continually being developed to make them smaller, more cost effective and more capable. Their ease of use makes them an increasingly effective solution for a wide range of applications in the smart factory, from logistics to safety, forming part of the factory network and sharing data to increase the integration of all systems.

Combined with artificial intelligence, vision systems have surged forward, reshaping the way manufacturing processes are conducted. These advanced systems combine modern computer vision with machine learning algorithms to analyse and interpret visual data, providing unparalleled efficiency, accuracy, and productivity on factory floors.

AI vision systems can be used for quality control and inspection, defect detection and prevention, intelligent robotics and automation, inventory management and supply chain optimisation, and worker safety. They can detect and analyse potential safety hazards, such as equipment malfunctions, improper tool usage, or unsafe working conditions.

Using an intelligent vision system provides a proactive approach, which helps prevent faulty products from reaching the market, thereby reducing customer complaints and minimising recall costs.

For more information, visit www.samtec.com

© Technews Publishing (Pty) Ltd | All Rights Reserved